Application of supported catalyst in cracking of trifluoromethane

A supported catalyst, trifluoromethane technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve high conversion rate, low cracking efficiency, and many by-products and other problems, to achieve the effects of high temperature resistance, strong acid corrosion resistance, improved use stability, high conversion rate and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Manganese chloride was used as a precursor, and acid-treated activated carbon supported manganese catalyst was prepared:

[0028] Activated carbon was treated with nitric acid with a mass concentration of 30% at 90°C for 5 hours, filtered, washed with water to neutrality, and the filter cake was baked at 120°C for 12 hours to obtain acid-treated activated carbon;

[0029] Impregnation method or impregnation fluorination method: Put 9.82g of manganese chloride into 10mL of deionized water, heat and stir to dissolve evenly, add 10g of acid-treated activated carbon carrier, stir evenly, let stand for 12h, then dry at 80°C for 12h, put into a quartz boat, 100mL / min nitrogen, roasted at 500°C for 4 hours to obtain activated carbon-loaded manganese solids, and then soak the solids in 10% HF aqueous solution for 1 hour, filter, wash with water, and dry at 80°C to obtain activated carbon-loaded manganese solids. Manganese catalyst, manganese mass loading is 30%.

[0030]Precip...

Embodiment 2

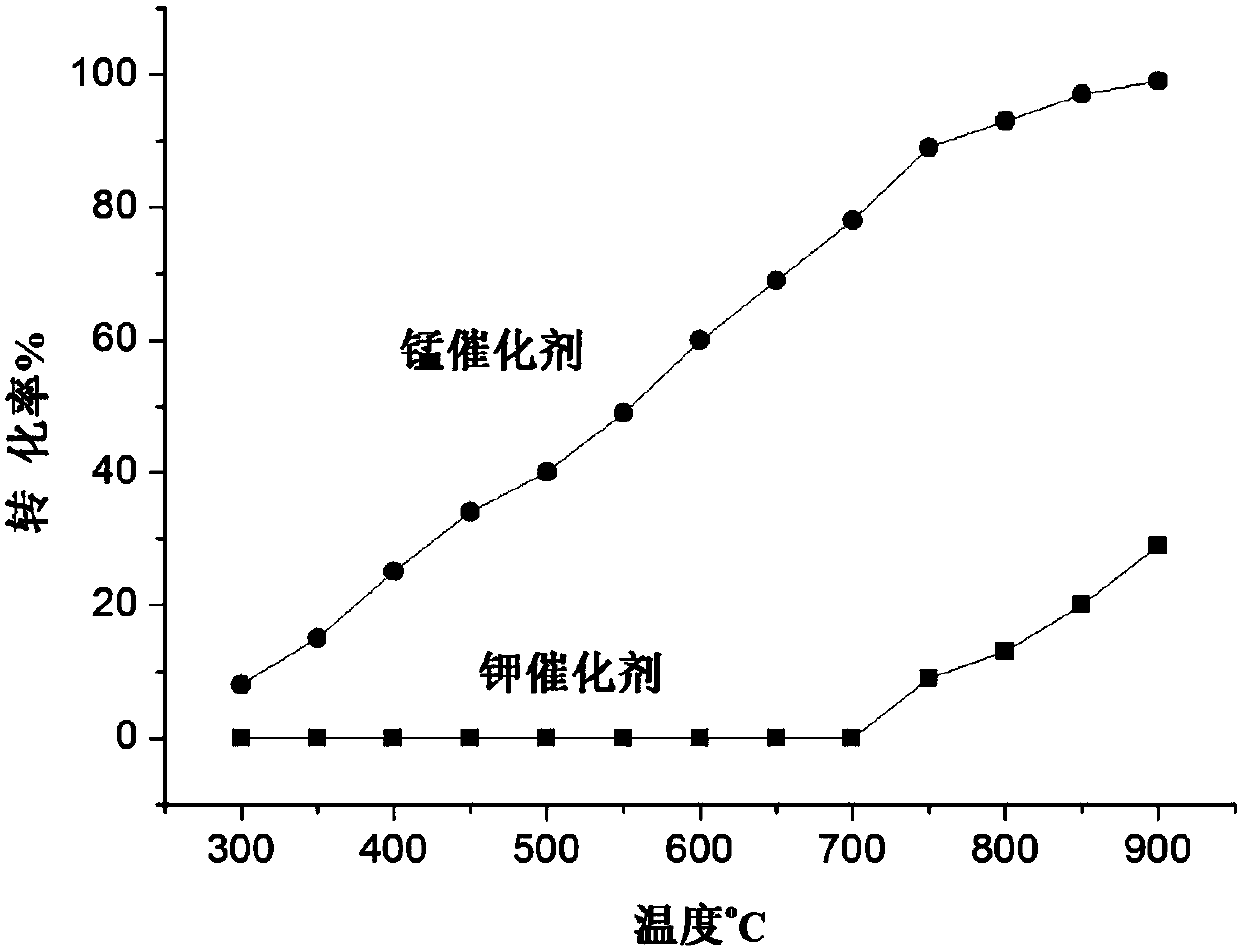

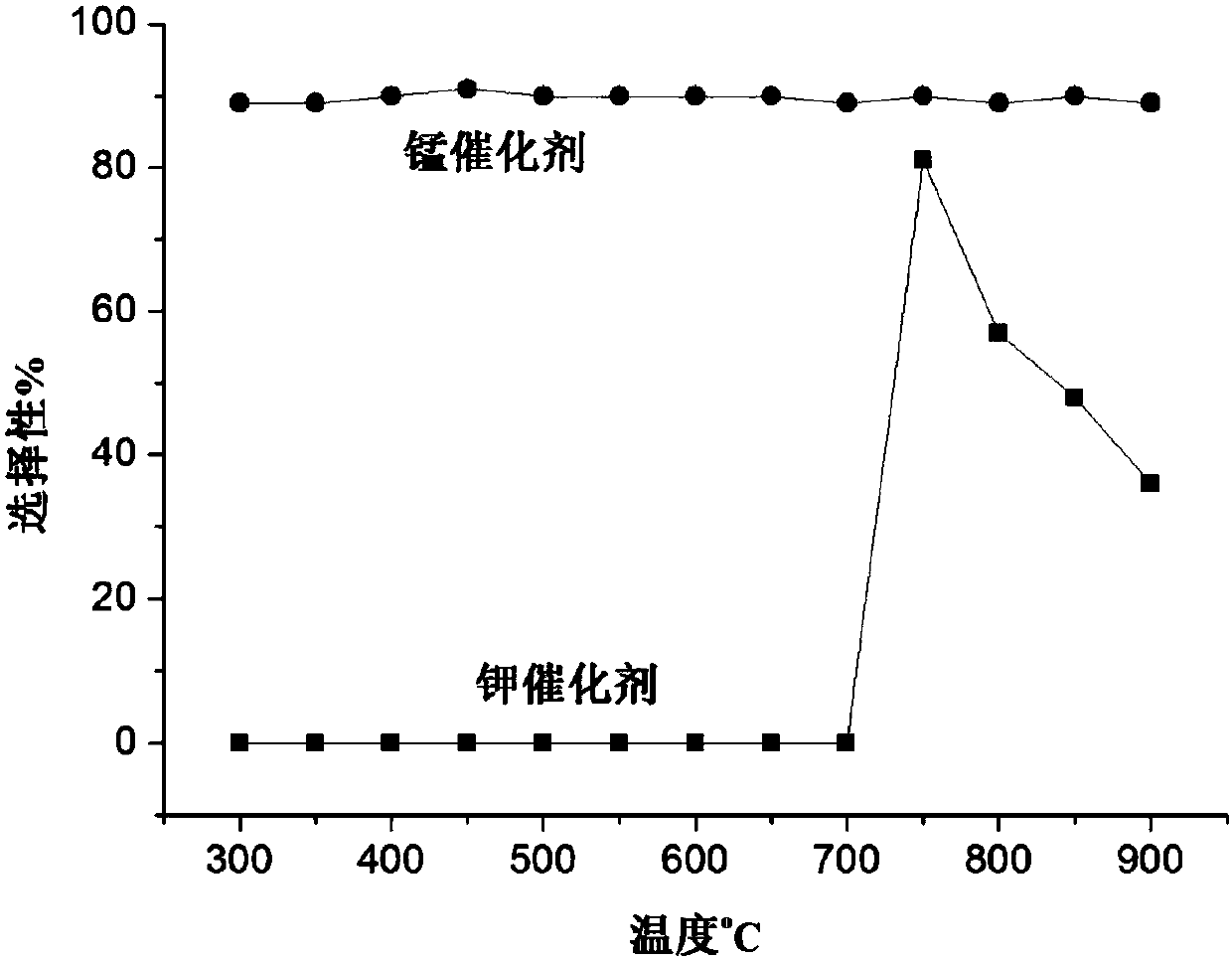

[0035] The trifluoromethane cracking catalytic activity under the catalyst test different temperature that adopts embodiment 1 to obtain: the 3g acid treatment activated carbon supported manganese catalyst that embodiment 1 obtains is packed into reaction tube, feeds trifluoromethane, and flow rate is 50mL / min, Then, the temperature of the reaction tube was raised from 300° C. to 900° C., and the temperature was kept constant for half an hour every time the temperature was increased by 50° C., and then analyzed by gas chromatography sampling. According to the change of trifluoromethane peak area before and after the reaction, the conversion rate from 300°C to 900°C was calculated; the selectivity was obtained by comparing the peak areas of tetrafluoroethylene and hexafluoropropylene standard products. The results are shown in Fig.

Embodiment 3

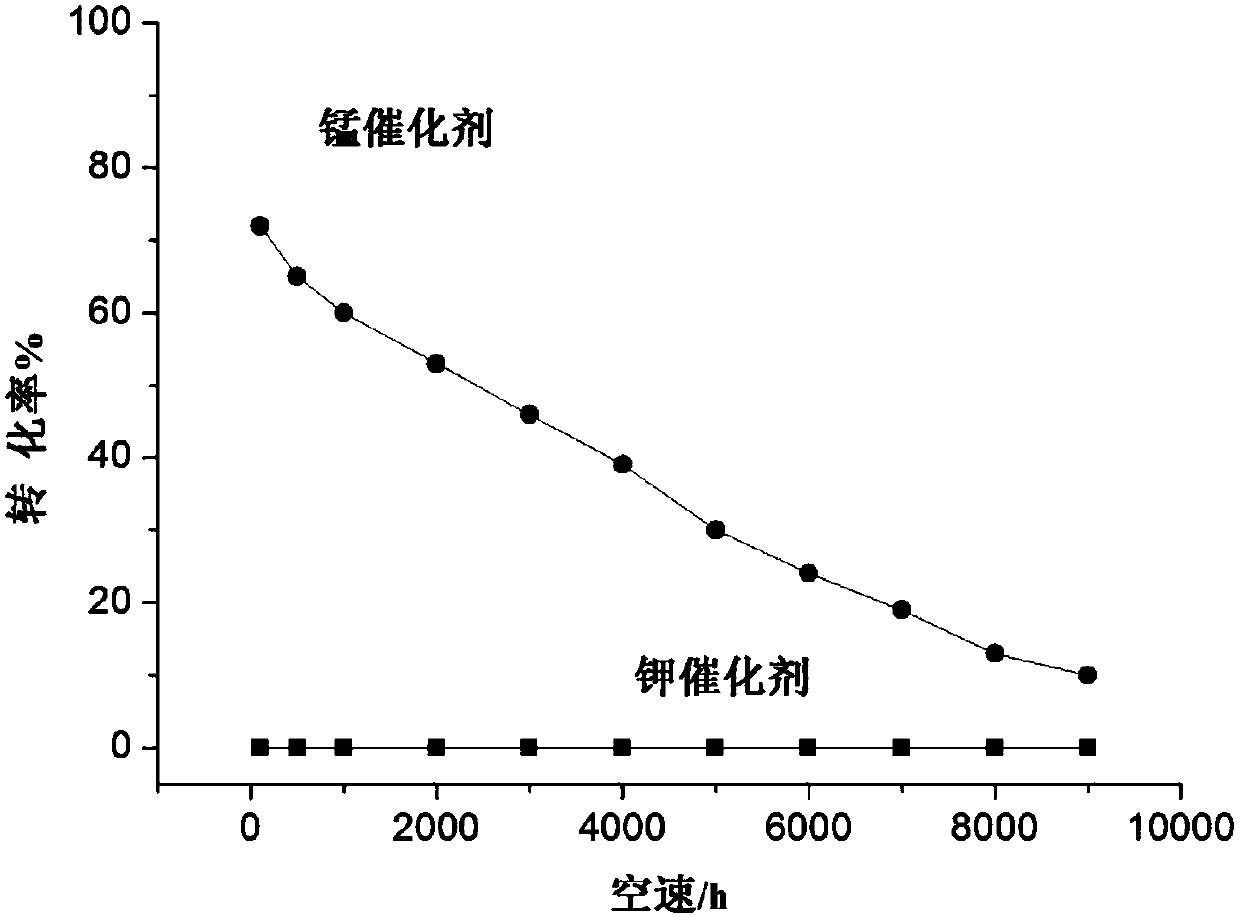

[0037] Using the catalyst obtained in Example 1 to test the trifluoromethane cracking catalytic activity under different space velocities: the 3mL acid-treated activated carbon-loaded manganese catalyst obtained in Example 1 is packed into the reaction tube, feeds trifluoromethane, adjusts the flow rate, and controls the space velocity The temperature is 100 / h-9000 / h, and then the temperature of the reaction tube is raised to 600°C for half an hour, and then analyzed by gas chromatography sampling. According to the change of trifluoromethane peak area before and after the reaction, the conversion rate at different space velocities was calculated; the selectivity was obtained by comparing the peak areas of tetrafluoroethylene and hexafluoropropylene standard products. The results are shown in Fig.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com