Fabric capable of generating electricity by means of airflow and preparation method and application of fabric

A fabric and airflow technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of poor flexibility, heavy weight, difficult to make into fibers or fabrics, etc., to achieve excellent flexibility and mechanical properties, easy to operate 、Structural stability and performance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a method for preparing fabrics that generate electricity by means of airflow, comprising the following steps:

[0048] S1, preparing flexible conductive yarn fabric: Winding the conductive silk core-spun yarn into a flexible conductive coil for a predetermined number of turns to form a closed loop, and sewing several flexible conductive coils in series on the fabric substrate to obtain a flexible conductive fabric of a predetermined size. yarn fabric, forming the coil conductor;

[0049] S2, preparation of flexible magnetic yarn fabric:

[0050] S21, preparing flexible fiber strips S1: cutting the non-woven flexible surface material with an area density of 2-100 g / m2 into flexible fiber strips S1 with a linear density of 10-800 g / km;

[0051] S22, preparation of composite fiber strip S2': demagnetize the magnetic powder, put the fiber strip S2 with a width of 10-20 mm and a linear density of 10-1000 g / km into the reaction vessel, conduct electric...

Embodiment 1

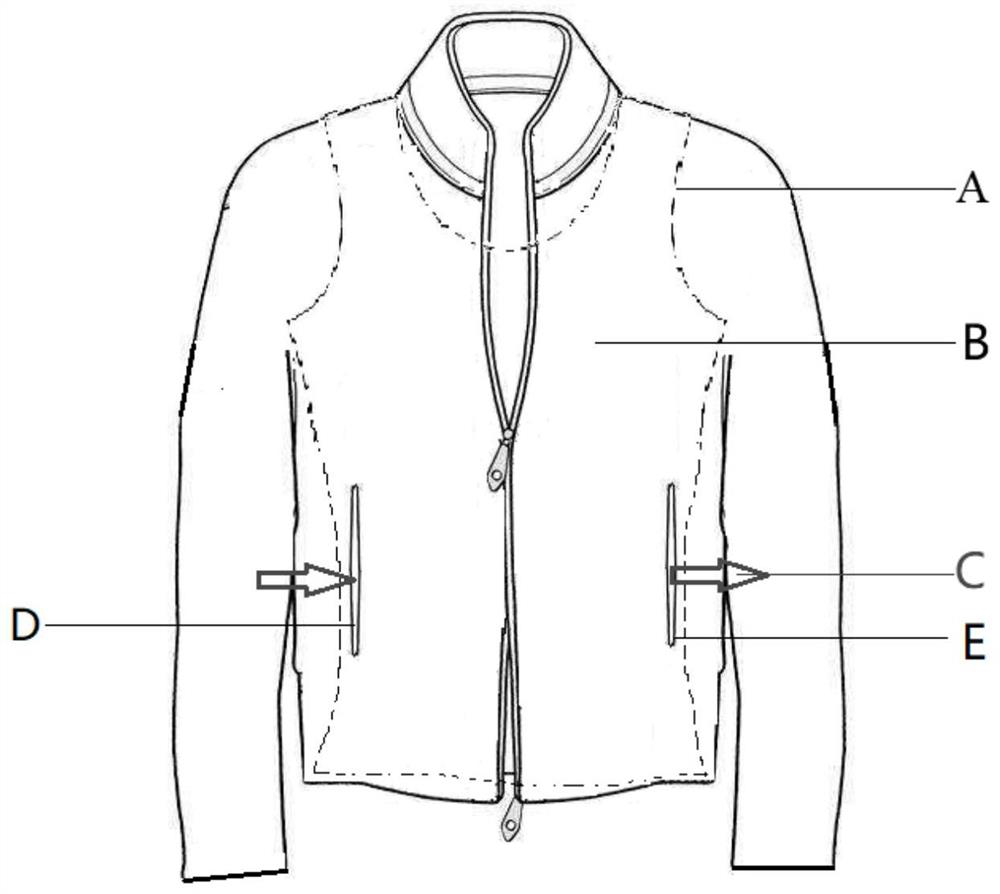

[0059] see figure 2 As shown, this embodiment provides a wearable garment that generates electricity by means of airflow. The garment includes a garment body and is designed as a double-layer structure. The preparation method thereof includes the following steps:

[0060] S1, prepare surface layer fabric:

[0061] Winding the conductive silk core-spun yarn 100 turns into a flexible conductive coil to form a closed loop, and connecting 40 flexible conductive coils in series and evenly dividing them into two groups, and sewing them symmetrically on the front of the garment body in pairs. The surface layer flexible conductive yarn fabric is prepared to form a coil conductor; the conductive filament core-spun yarn is provided with conductive filaments, the conductive filaments are copper wires, and the diameter of the conductive filaments is 0.05mm;

[0062] S2, preparing inner layer fabric:

[0063] S21, preparing flexible fiber strips S1: cutting the non-woven flexible surfac...

Embodiment 2

[0072] see image 3 As shown, the present embodiment provides a field surgical vest with the help of airflow power generation. The vest includes a vest body and is designed as a double-layer structure. The preparation method includes the following steps:

[0073] S1, prepare surface layer fabric:

[0074] S211, preparing flexible fiber strips S1: cutting the non-woven flexible surface material with an area density of 40 g / m2 into flexible fiber strips S1 with a linear density of 800 g / km;

[0075] S12, preparation of composite fiber strip S2': demagnetize the magnetic powder, put the fiber strip S2 with a width of 20 mm and a linear density of 500 g / km into the reaction vessel, and polymerize the conductive polymer in situ. The conductive polymer is grown on the fiber strip, and after being pulled, dried and dried, a composite fiber strip with a conductive polymer is obtained; the composite fiber strip is immersed in magnetic powder with a particle size of 500nm, magnetic pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com