Low-cost heating agent for converter and production method

A production method and technology of exothermic agent, which are applied in the field of iron and steel metallurgy, can solve the problem of not developing a recovery technology with better economic benefits and environmental protection benefits, and achieve the effects of excellent heating effect, low cost and excellent heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

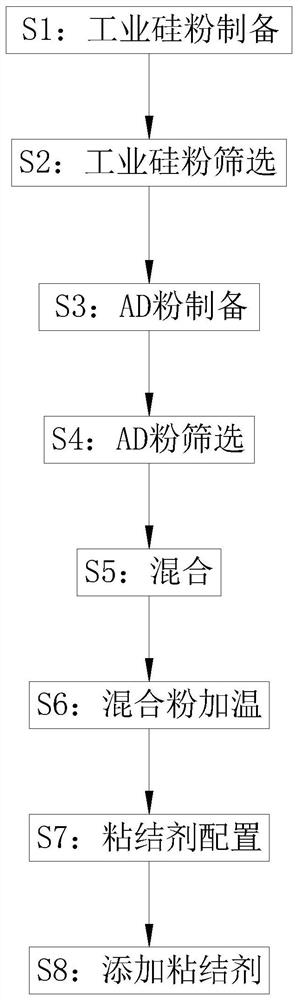

Method used

Image

Examples

Embodiment 1

[0042] A low-cost heating agent for converter steelmaking, including industrial silicon powder, AD powder, binder, and additives. The percentage by weight is: 65% of industrial silicon powder; 25% of AD powder; 3% of binder; 7% of silicon carbide.

Embodiment 2

[0044] A low-cost heating agent for converter steelmaking, including industrial silicon powder, AD powder, binder, and additives. The weight percent is: industrial silicon powder 75%; AD powder 15%; binder 2%; silicon carbide 8%.

Embodiment 3

[0046] A low-cost heating agent for converter steelmaking includes industrial silicon powder, AD powder, binder and additives. Its weight percent is: industrial silicon powder 80%; AD powder 17%; binder 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com