Industrial waste salt refining and purifying coupling process and device

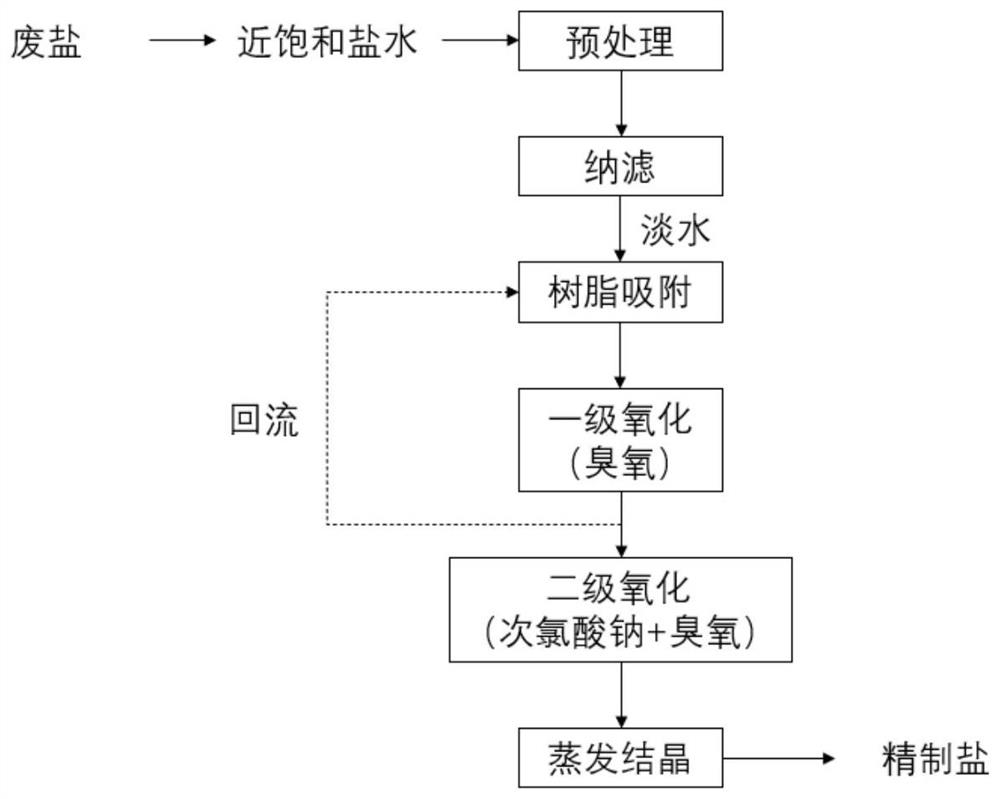

An industrial waste salt and process technology, applied in the field of industrial waste salt refining and purification coupling processes and devices, can solve the problems of inability to effectively reduce TN and high treatment costs, and achieve the effects of reducing TN, low treatment costs, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

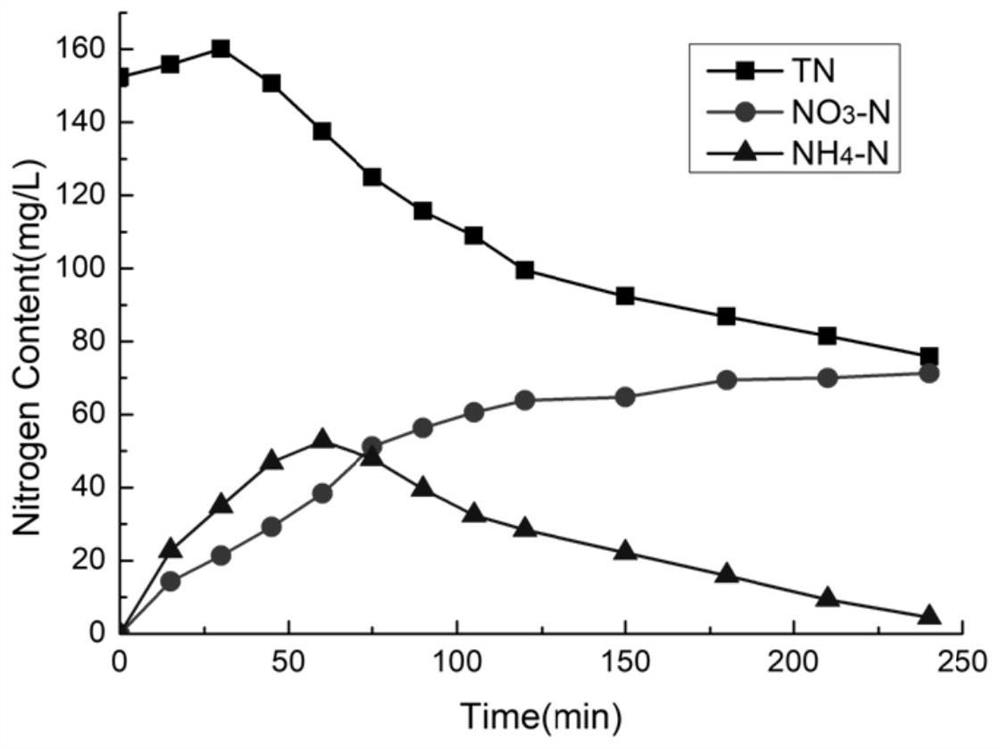

[0056] Atrazine waste salt was treated by nanofiltration separation-resin adsorption-multistage oxidation combined process. The TOC content in the waste salt is 600.7mg / kg, the TN content is 430.2mg / kg, and the impurities are mainly organic substances such as atrazine, propazine, simazine, and cyanuric chloride.

[0057] Step 1. Use a forklift to transport the waste salt into the salt tank to prepare nearly saturated brine, pre-treat to remove insoluble matter, and then pump it into the water inlet tank of the nanofiltration separation device; specifically: dissolve sodium chloride salt in deionized water Make nearly saturated brine, use sand filtration and ultrafiltration (hollow fiber PVDF ultrafiltration membrane, molecular weight cut-off 300000-500000) to remove large particles of insoluble matter in brine, at this time the brine TOC is 289.5mg / L, TN is 152.4 mg / L, and then enter the nanofiltration separation step;

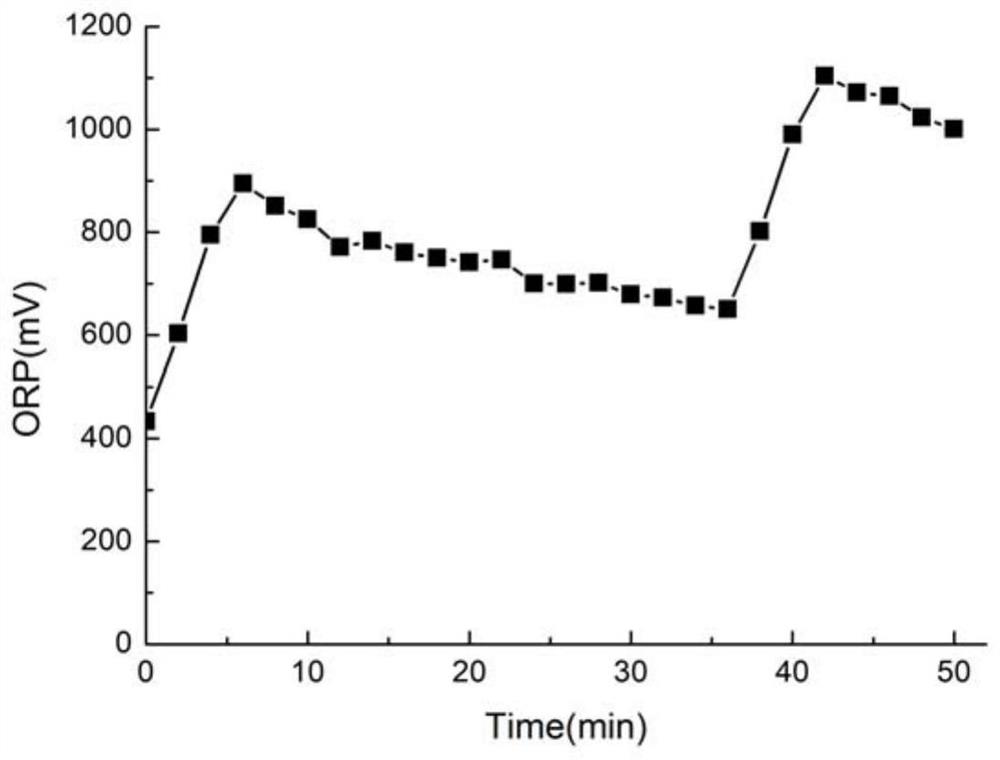

[0058] Step 2. Adjust the pH of the brine, pump the bri...

Embodiment 2

[0079] The combined process of nanofiltration separation-resin adsorption-multistage oxidation was used to treat the waste salt of propiconazole. The TOC content in the waste salt is 530mg / kg, the TN content is 196.1mg / kg, and the impurities are mainly organic substances such as propiconazole, N-methylpyrrolidone, and dimethyl sulfide.

[0080] Step 1. Use a forklift to transport the waste salt into the salt tank to prepare nearly saturated brine, pre-treat to remove insoluble matter, and then pump it into the water inlet tank of the nanofiltration separation device; specifically: dissolve sodium chloride salt in deionized water Make nearly saturated brine, use sand filtration and ultrafiltration (hollow fiber PVDF ultrafiltration membrane, molecular weight cut-off is 300000-500000) to remove large particles of insoluble matter in brine, at this time the brine TOC is 159mg / L, TN is 58.9mg / L, then enter the nanofiltration separation step;

[0081] Step 2. Adjust the pH of the...

Embodiment 3

[0102] The combined process of nanofiltration separation-resin adsorption-multistage oxidation was used to treat the waste salt of tebuconazole. The TOC content in the waste salt is 1010.8mg / kg, the TN content is 413.1mg / kg, and the impurities are mainly other organic substances.

[0103] Step 1. Use a forklift to transport the waste salt into the salt tank to prepare nearly saturated brine, pre-treat to remove insoluble matter, and then pump it into the water inlet tank of the nanofiltration separation device; specifically: dissolve sodium chloride salt in deionized water Make nearly saturated brine, use sand filtration and ultrafiltration (hollow fiber PVDF ultrafiltration membrane, molecular weight cut-off 300000-500000) to remove large particles of insoluble matter in brine, at this time the brine TOC is 337.3mg / L, TN is 113.5 mg / L, and then enter the nanofiltration separation step;

[0104] Step 2. Adjust the pH of the brine, pump the brine into the nanofiltration separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com