Photothermal Microfluidic Mixer Based on Single Hole Optical Fiber

A mixer and microfluidic technology, applied in the field of optofluidics, can solve the problems of complex technology and size requirements, high cost, cumbersome preparation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0037] figure 1 The cross-sectional structure of the single-hole fiber is shown, the single-hole fiber is composed of air holes 1-1 that can enter the microfluidic liquid, and the core 1-2 and cladding 1-3 structures with a refractive index slightly higher than that of the cladding material consist of.

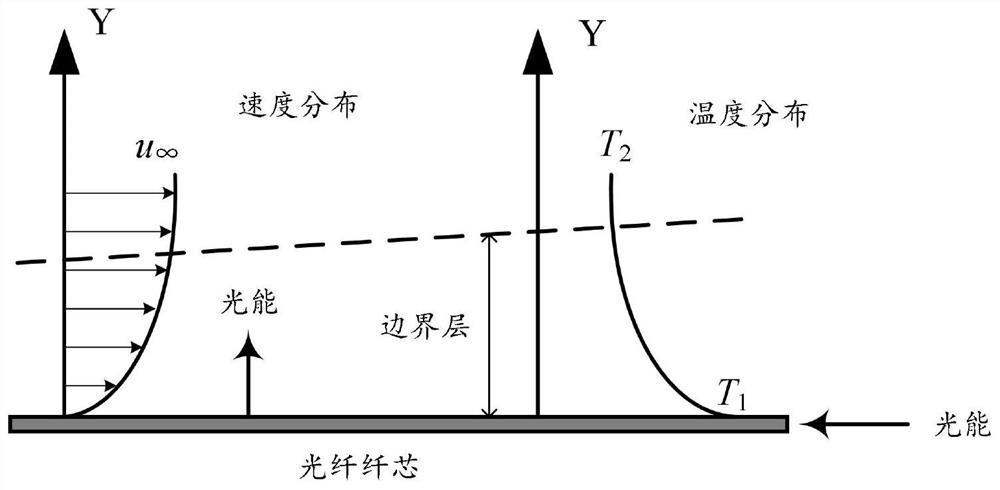

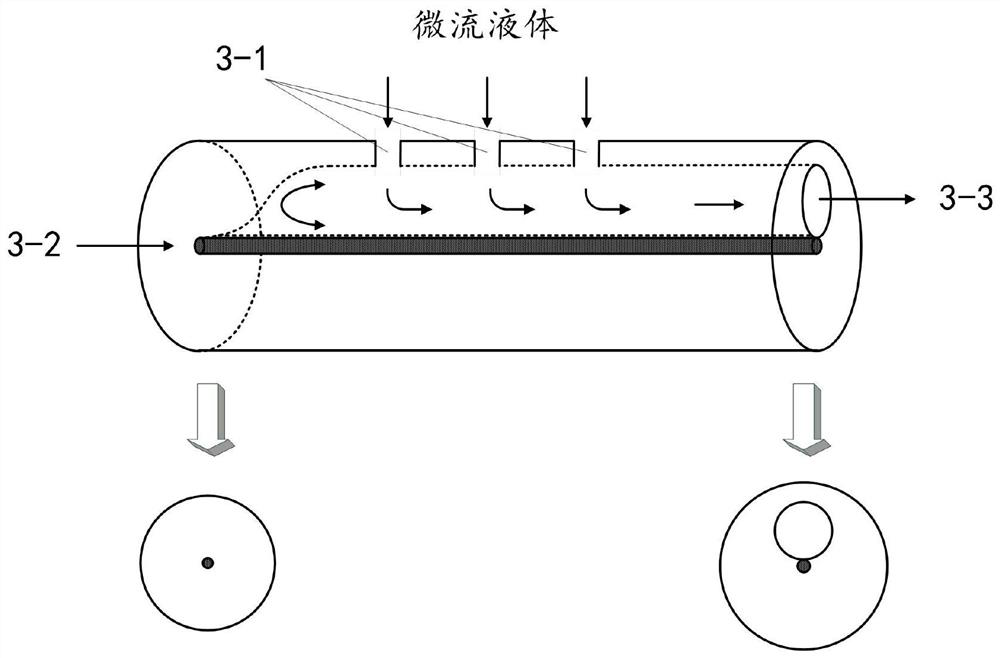

[0038] image 3 It shows the structure of processing a single-hole optical fiber into a photothermal microfluidic mixer, and preparing a plurality of micro-holes outside the air hole. Tangent, after passing in light energy, heat energy radiation is generated to the microfluidic liquid, which makes the liquid molecules accelerate to achieve the purpose of mixing.

[0039] Without loss of generality, we use image 3 The specific embodiment of the single-hole optical fiber photothermal microfluidic mixer shown is used to describe the specific im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com