A low-cost q355c steel plate production process

A production process and low-cost technology, applied in the field of steel plates, can solve problems such as difficult to achieve low-cost production and high prices, and achieve the effect of improving 0°C impact toughness and compensating for strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Steel species: Q355C; 2. 20 mm thickness thickness; rolled product specification: 16mm; quantity: 8 pieces, total 80.20t.

[0035] 1, smelting component: C = 0.17%, Si = 0.30%, Mn = 1.45%, P = 0.015%, S = 0.012%, Alt = 0.025%;

[0036] The slab is low, H content is 2.5 ppm, t [o]: 20 ppm; N content 44 ppm.

[0037] 2, average heat temperature: 1200 ° C; rough rolling temperature: 1130 ° C; finished rolling temperature: 950 ° C; final rolling temperature 840 ° C; ACC finishing temperature 680 ° C.

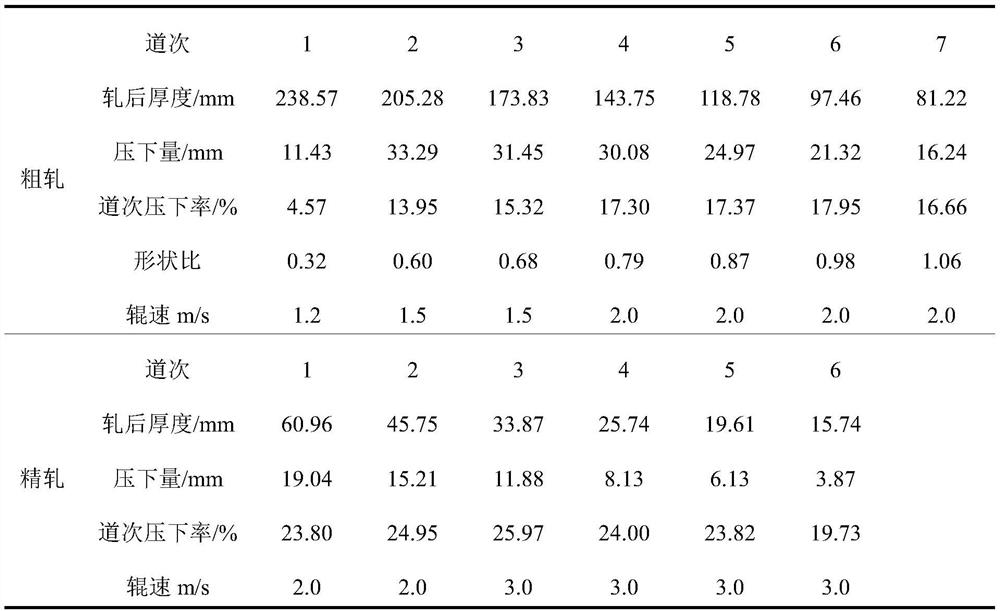

[0038] 3, the crude rolling channel is assigned to 7 / 7, the intermediate blank 80mm, the intermediate blank is compressed ratio 5, and the specific parameters are shown in Table 1.

[0039] Table 1 Example 1 Scene of rolling channel

[0040]

[0041] 4, the steel sheet is rolled down the line to pile up, the lower line temperature is 250 ° C.

[0042] 5, the steel sheet is piled up to the room temperature and then dismantled automatic flaw, the detection standard is GB / T 2970...

Embodiment 2

[0047] Steel species: Q355C; 2. 20mm thickness thickness; rolled product specification: 30mm; quantity: 7, a total of 85.23t.

[0048]1, smelting component: C = 0.15%, Si = 0.35%, Mn = 1.51%, P = 0.018%, S = 0.010%, Alt = 0.025%;

[0049] The slab is low, the H content is 2.5 ppm, T [o]: 22 ppm; N content 49 ppm.

[0050] 2, average heat temperature: 1180 ° C; rough rolled rolling temperature: 1100 ° C; finishing rolling temperature: 910 ° C; final rolling temperature 840 ° C; ACC finishing at 10 ° C.

[0051] 3, the crude rolling channel is assigned to 7 / 7, the intermediate blank is 110mm, the intermediate blank is compressed ratio 3.7, and the specific parameters are shown in Table 3.

[0052] Table 3 Example 2 Rolling Channel

[0053]

[0054] 4, the steel sheet is rolled off the line to the lower line, the lower line temperature is 280 ° C.

[0055] 5, the steel sheet is piled up to the room temperature and then dismantled automatic flaw, the detection standard is GB / T 297...

Embodiment 3

[0060] Steel species: Q355C; 2. 200 mm thickness of the die; rolled finished product specification: 50mm; quantity: 6 pieces, total 78.72t.

[0061] 1, smelting component: C = 0.18%, Si = 0.32%, Mn = 1.56%, P = 0.017%, S = 0.008%, Alt = 0.030%;

[0062] The slab is low, H content 1.8 ppm, T [o]: 20 ppm; N content 46 ppm.

[0063] 2, average heat temperature: 1160 ° C; rough rolling, rolling temperature: 1090 ° C; finishing rolling temperature: 870 ° C; final rolling temperature 850 ° C; ACC refrigeration temperature 630 ° C.

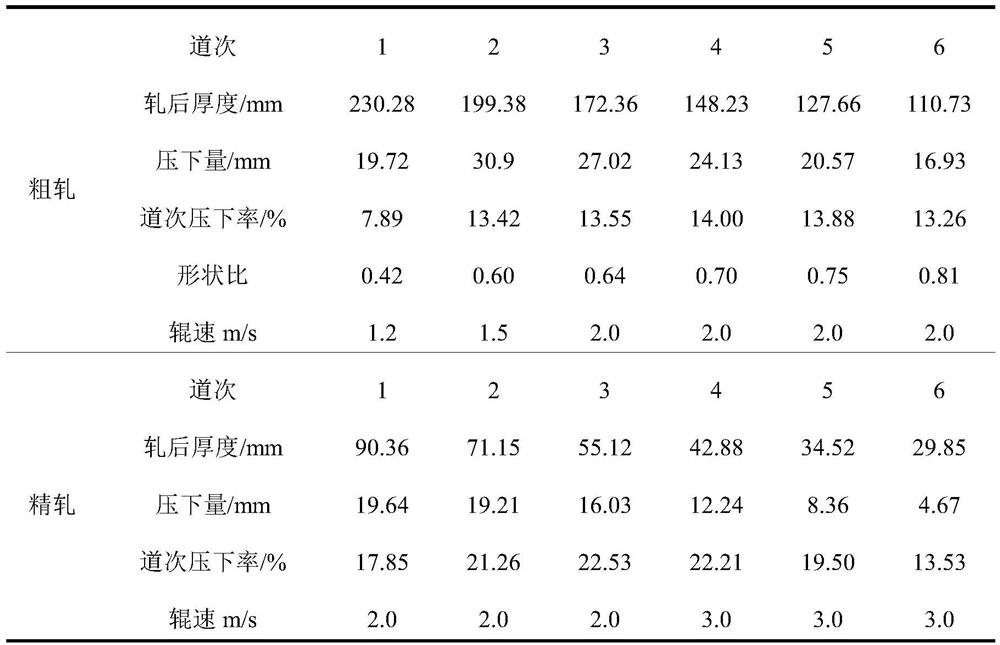

[0064] 3, the coarse rolling channel is assigned to 5 / 7, the intermediate blank is 150mm, the intermediate blank compression ratio 3, and the specific parameters are shown in Table 5.

[0065] Table 5 Example 3 Rolling Channel

[0066]

[0067] 4, the steel plate rolling is lowered, and the line is piled up, the lower line temperature is 310 ° C.

[0068] 5, the steel sheet is piled up to the room temperature and then dismantled automatic flaw, the detecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com