A water-based permeable crystalline concrete surface repair reinforcement material and its preparation method and application

A technology of infiltrating crystallization and reinforcing materials, applied in the field of concrete building materials, can solve the problems of long curing time and low reaction rate, and achieve the effects of accelerating the speed and strength, high reactivity, and insignificant improvement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

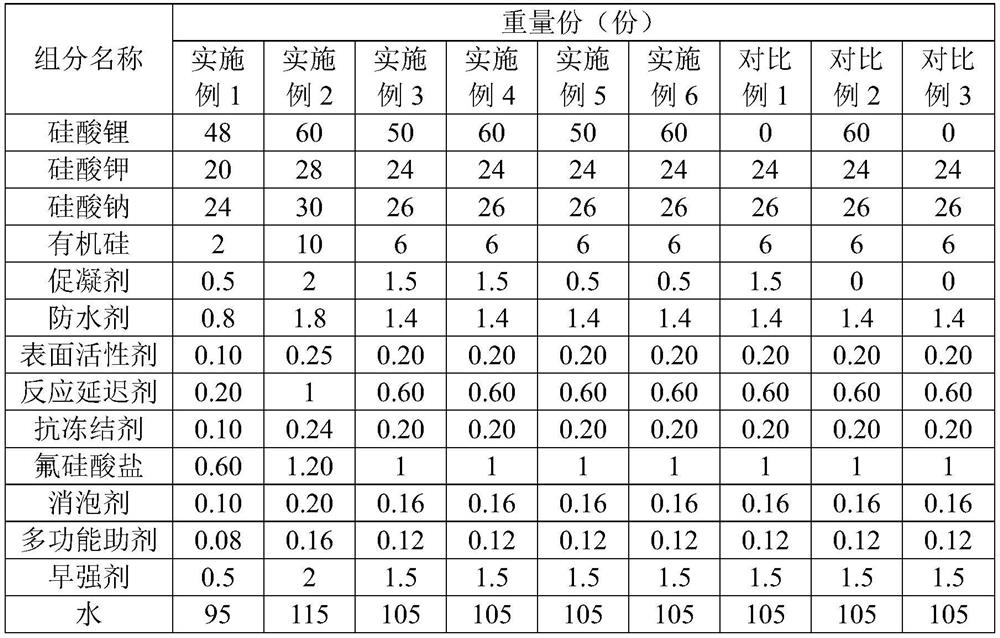

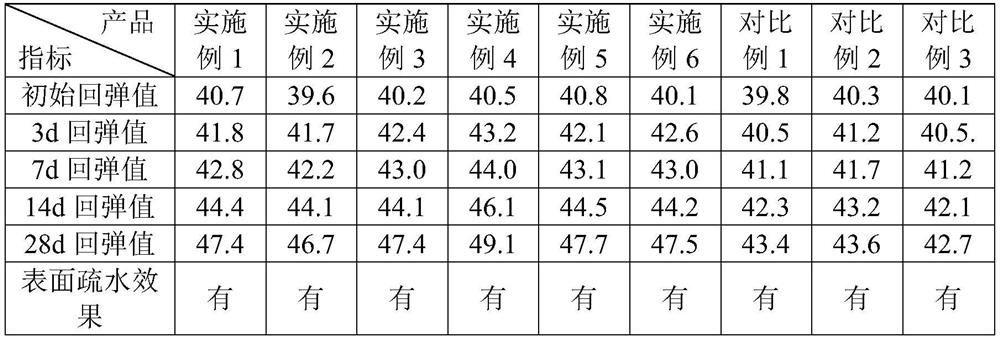

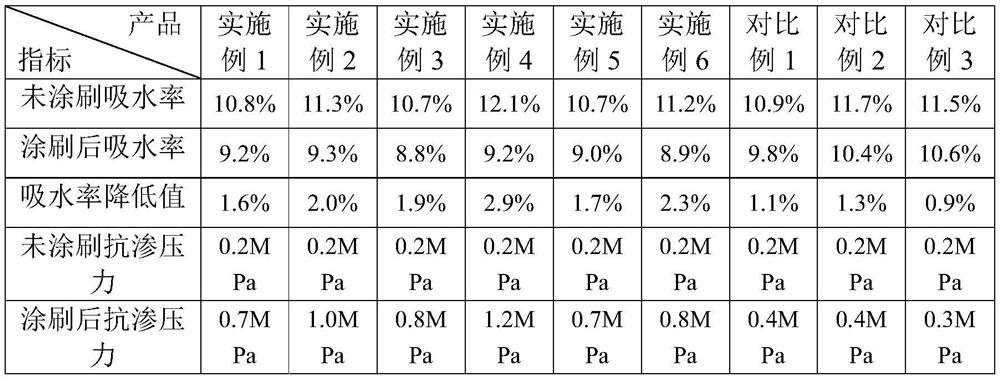

[0060] The specific formula of water-based permeable crystalline concrete surface repair reinforcing material is shown in Table 1.

[0061] Wherein embodiment 3 and 4, embodiment 5 and 6 are respectively aimed at the comparison of different parts of lithium silicate, embodiment 3 and 5, embodiment 4 and 6 are respectively aimed at the comparison of different parts of coagulant.

[0062] Table I

[0063]

[0064] Wherein, the lithium silicate solution is an aqueous lithium silicate solution with a mass fraction of 20%, the potassium silicate solution is an aqueous potassium silicate solution with a mass fraction of 30%, the sodium silicate solution is an aqueous sodium silicate solution with a mass fraction of 40%, and the organosilicon is Potassium methyl silicate, sodium formate as a coagulant, sodium stearate as a waterproofing agent, sodium dodecylsulfonate as a surfactant, citric acid as a reaction delay agent, potassium carbonate and fluorosilicate as an antifreeze age...

Embodiment 7

[0072] Example 7 has the same components as Example 4, except that the lithium silicate solution is an aqueous lithium silicate solution with a mass fraction of 30%, the potassium silicate solution is an aqueous potassium silicate solution with a mass fraction of 40%, and the sodium silicate solution It is an aqueous solution of sodium silicate with a mass fraction of 30%, the organosilicon is magnesium methyl silicate, the coagulant is potassium formate, the waterproofing agent is potassium stearate, the surfactant is sodium dodecylsulfonate, and the reaction delay agent for citric acid. The antifreeze agent is potassium carbonate, and the fluorosilicate is sodium fluorosilicate.

Embodiment 8

[0074] Example 8 has the same components as Example 4, except that the lithium silicate solution is an aqueous lithium silicate solution with a mass fraction of 25%, the potassium silicate solution is an aqueous potassium silicate solution with a mass fraction of 35%, and the sodium silicate solution It is an aqueous solution of sodium silicate with a mass fraction of 35%, and the fluorosilicate is ammonium fluorosilicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com