A high-efficiency and precise repair method for ring pipes with complex structures of engines

A technology with complex structure and engine, applied in tubular articles, auxiliary welding equipment, welding equipment, etc., can solve the problems of high positioning accuracy, low production efficiency, long loop processing cycle, etc., to improve assembly positioning accuracy and production. Efficiency, the effect of shortening the assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

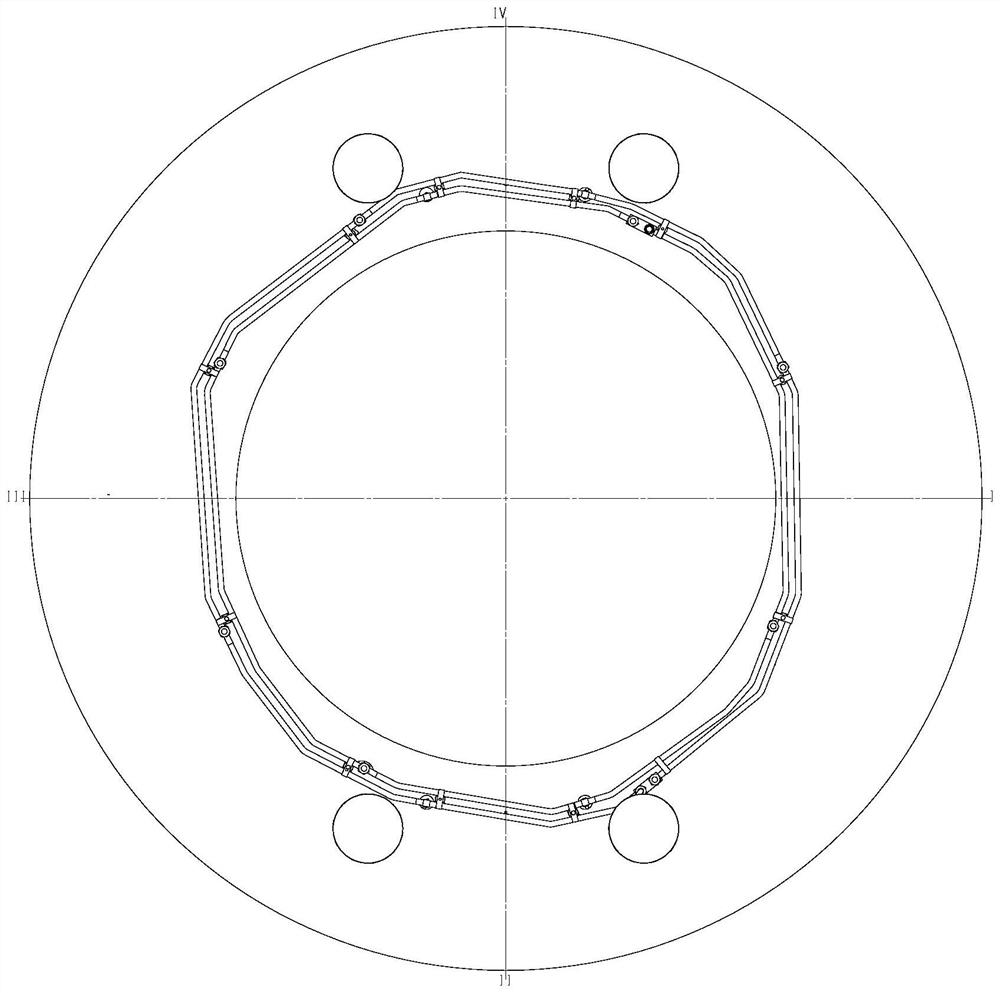

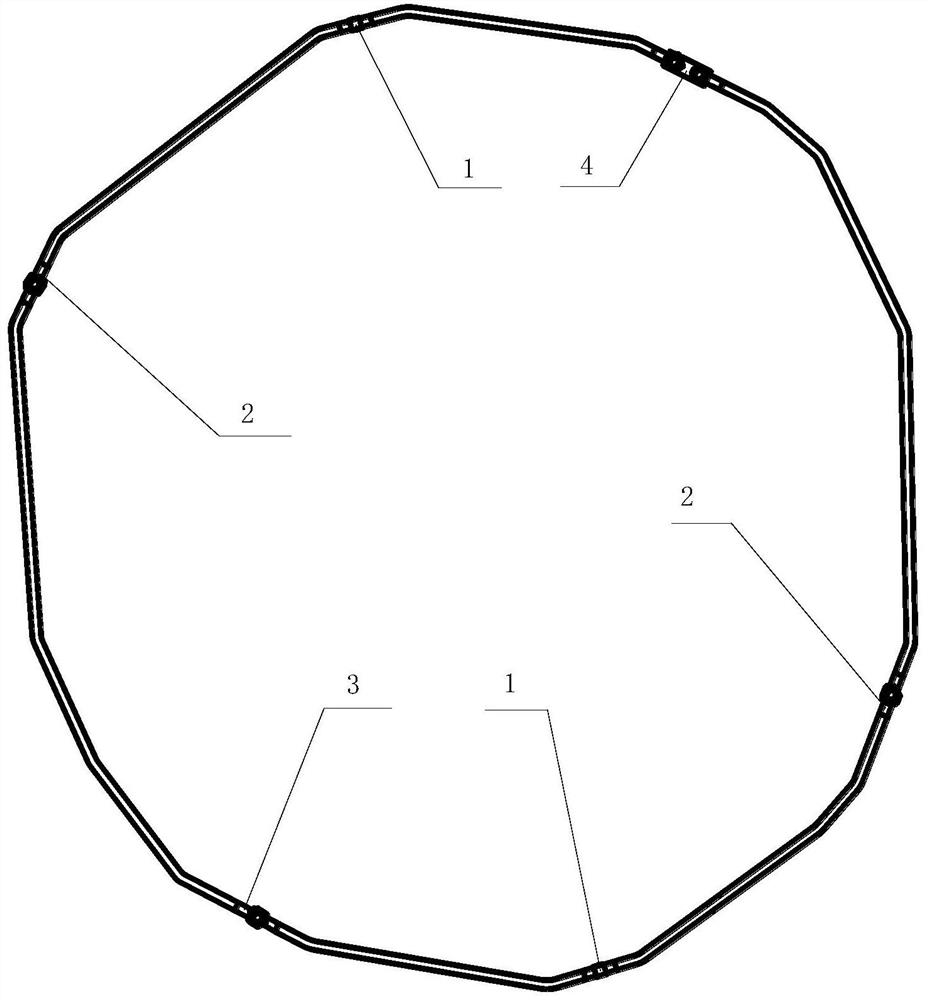

[0019] The invention provides an efficient and precise repairing method for the ring pipe of the engine with a complex structure. The ring pipe includes two ring pipes, the inner and outer ring pipes. A series of tooling is used to simultaneously position each connection on the two ring pipes, so that the two ring pipes can be completed at one time. Repairing, described technological method comprises the following steps:

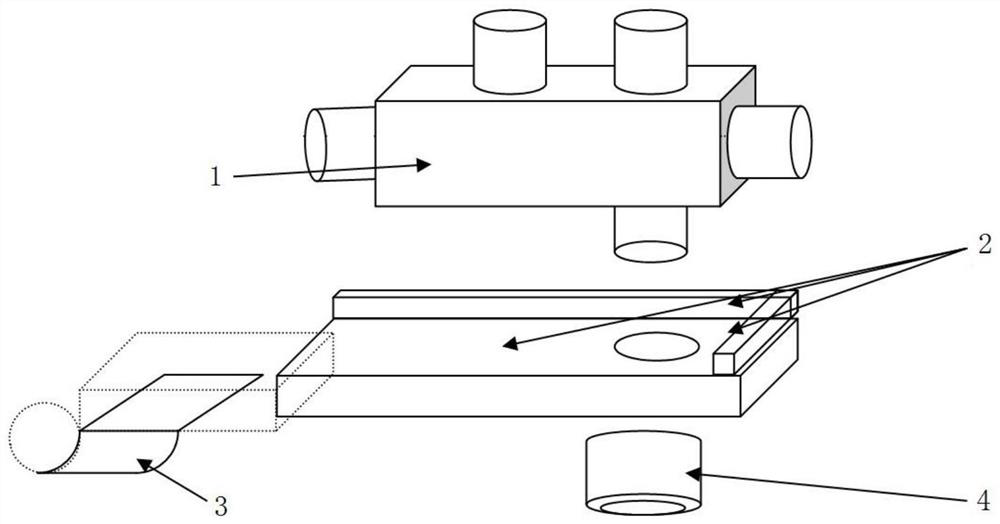

[0020] (1) The base of the tooling is installed on the cabin body through bolts, and at the same time, the guide hoop is installed to be flattened with the base, and the connecting bolts are tightened;

[0021] (2) The lower end of the tooling base is connected to an overcoat nut with a guide section, the overcoat nut is connected to the connection nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com