Beam shaping structure for improving laser cutting of flexible OLED module and method thereof

A laser cutting and beam shaping technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as affecting processing quality, reducing edge energy, and weakening the degree of haze, to ensure the effect of processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

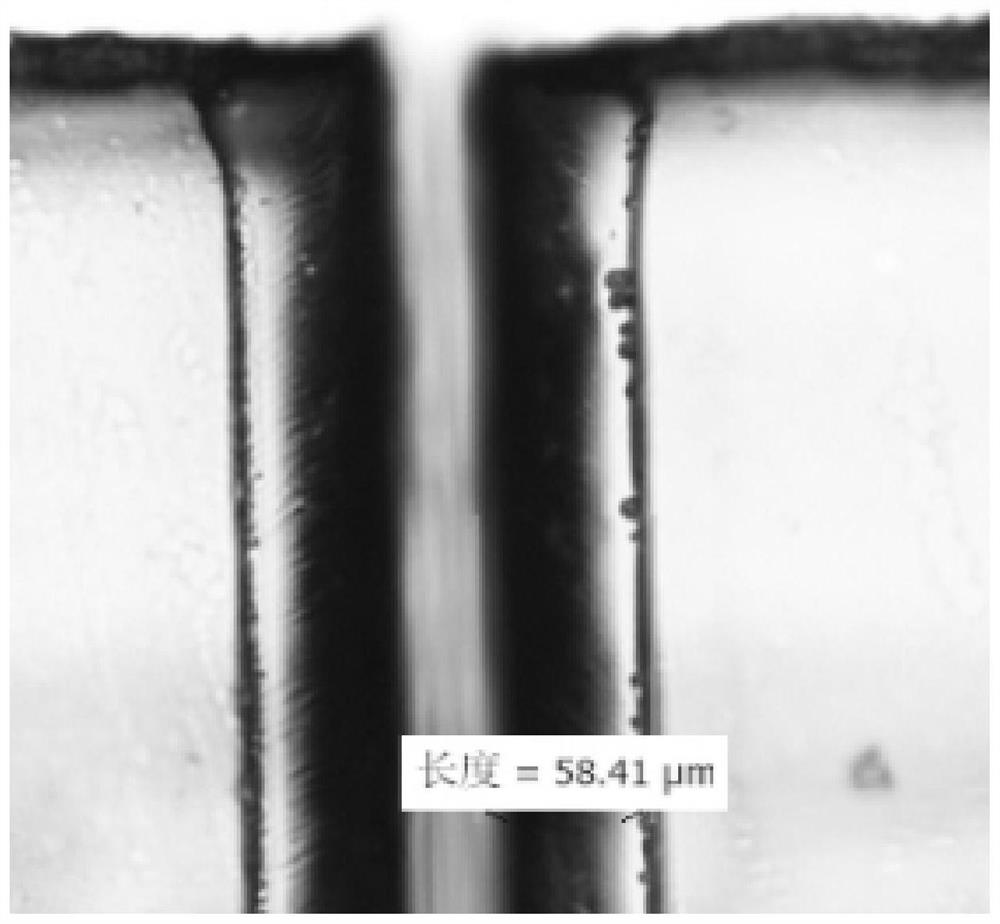

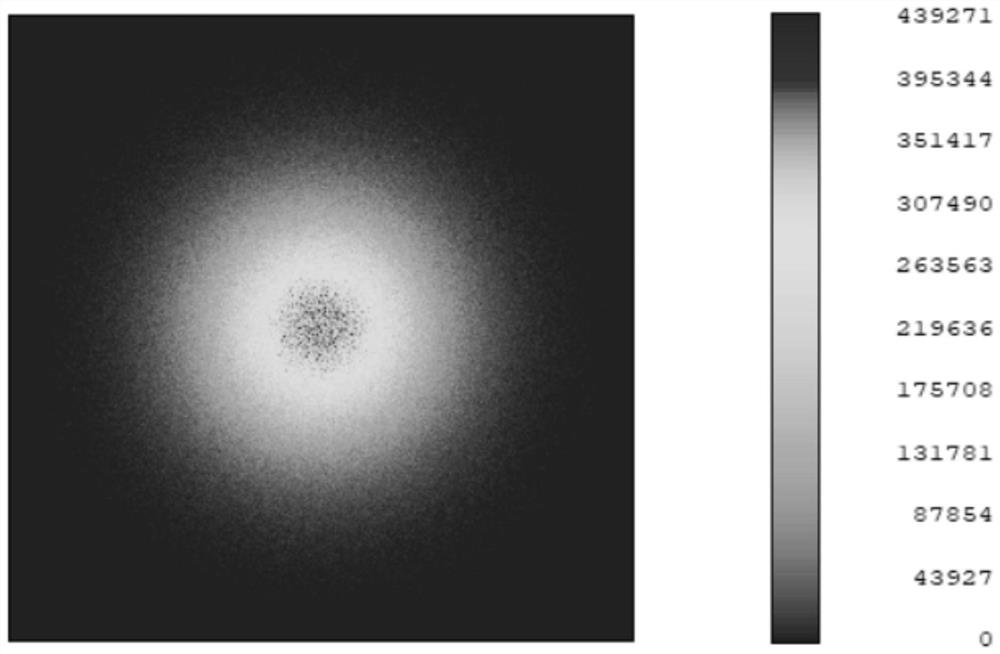

[0037] In this embodiment, a beam shaping structure is provided to improve the laser cutting of flexible OLED modules. The laser emits a Gaussian beam for shaping, and removes the energy distributed around the Gaussian spot. Use ZEMAX software to design and verify that the optical structure can be realized. Transformation of Gaussian beams. Its overall working principle is: the laser emits a Gaussian beam. After the Gaussian beam is converted by the optical composition I, the Gaussian beam is shaped to remove the energy of the edge, and then the laser cutting lens is used to focus, and then cut on the processing surface. A larger range of Haze will be generated on the surface of the processed product to reduce Haze.

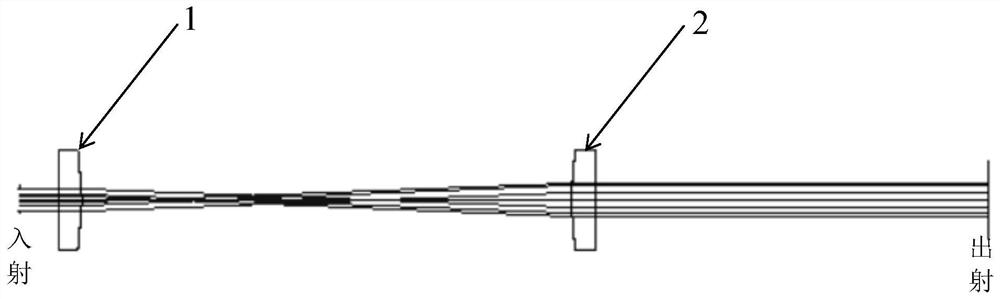

[0038] Such as image 3 As shown, the optical configuration I includes: a first axicon lens and a second axicon lens arranged on the light propagation path from the incident light beam to the exit light beam, the first axicon lens and the second axicon lens form...

Embodiment 2

[0055] In this embodiment, another beam shaping structure is provided to improve the laser cutting of flexible OLED modules. The laser emits a Gaussian beam for shaping, removes the energy distributed around the Gaussian spot, uses ZEMAX software to design, and verifies that the optical structure can be Realize the transformation of Gaussian beam. Its overall working principle is: the laser emits a Gaussian beam. After the Gaussian beam is converted by the optical composition II, the Gaussian beam is shaped to remove the energy of the edge, and then the laser cutting lens is used to focus, and then cut on the processing surface. A larger range of Haze will be generated on the surface of the processed product to reduce Haze.

[0056] Such as Figure 4 As shown, the optical configuration II includes: a first conical reflector and a second conical reflector arranged on the light propagation path from the incident light beam to the outgoing light beam, the first conical reflector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com