Quick change press head for shaping oil press

A hydraulic press and pressure head technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of occupying production man-hours and high labor intensity, and achieve the effects of fast replacement, reduced labor intensity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

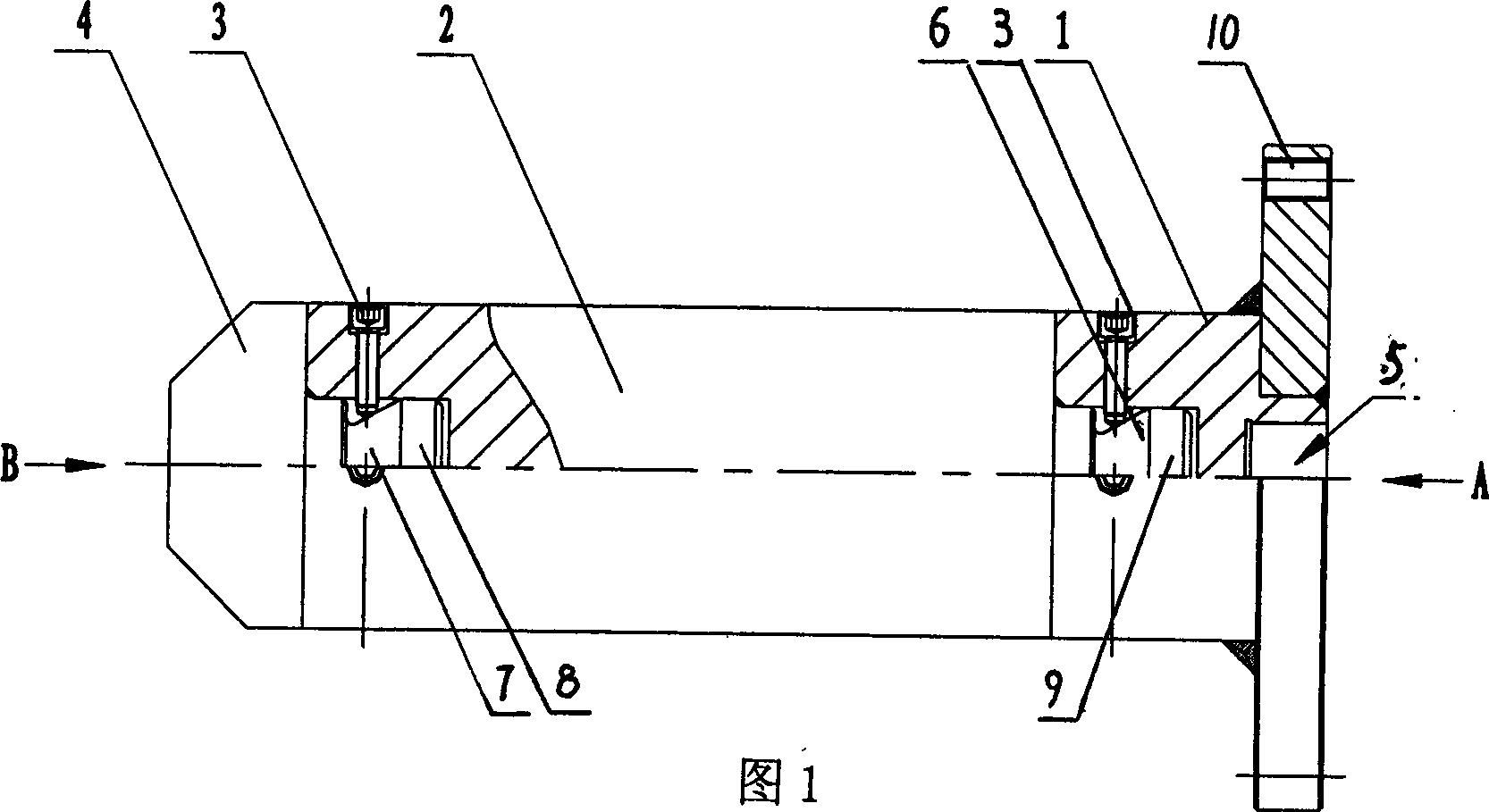

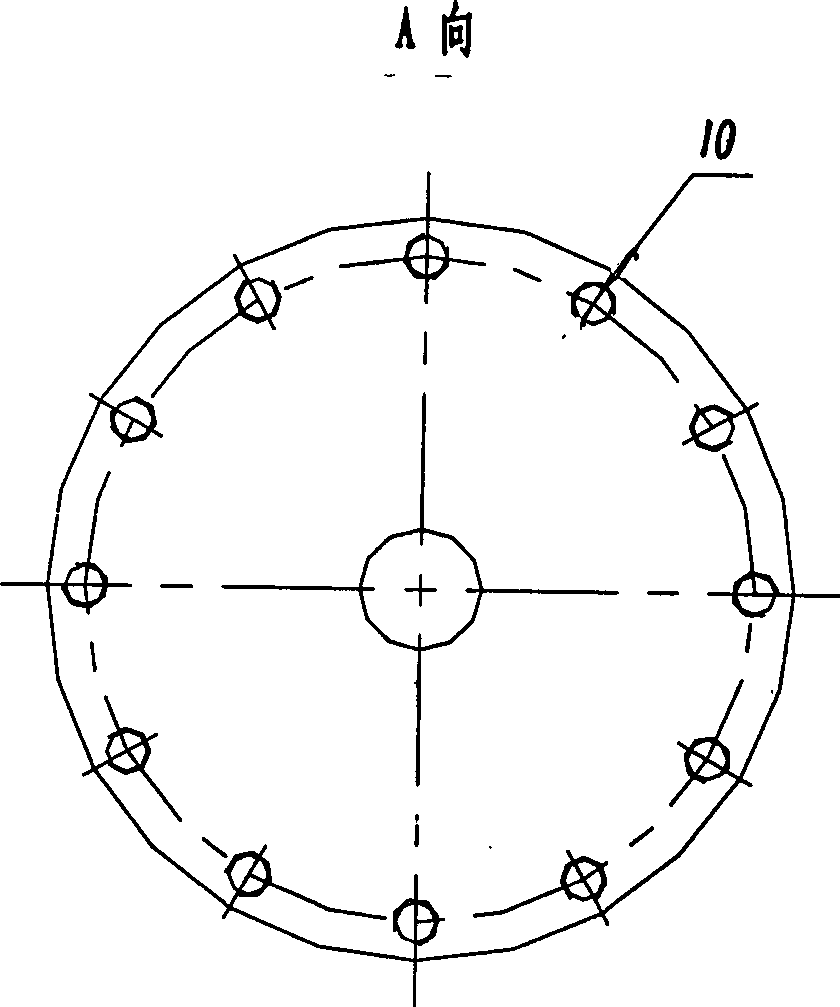

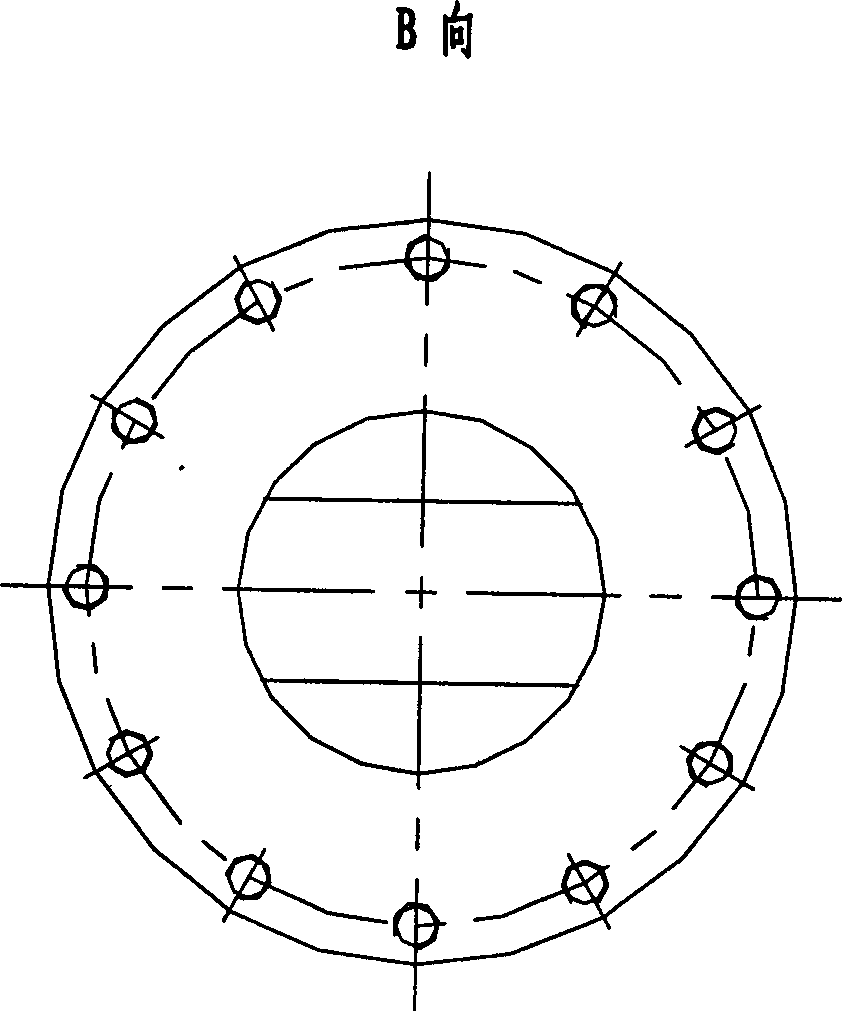

[0014] As shown in Figures 1, 2, and 3, the connecting flange of the indenter connecting body 1 of the present invention is provided with connecting fastening threaded holes 10 according to equipment connecting standards. The connecting end of the indenter connecting body 1 and the plunger of the machine tool is provided with an installation centering spigot 5, which is used to determine the mutual position between the indenter connecting body 1 and the equipment plunger, and the other end of the indenter connecting body 1 is provided with a standard connection positioning Heart stop mouth 9. The length of the extension section 2 is determined according to the minimum thickness of the plate to be leveled. One end of the extension section 2 is provided with a conical locking shaft head 6, and the other end is provided with the same connection centering spigot 8 as the indenter connector 1, so that the conical locking shaft head 7 of the indenter 4 can be inserted into the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com