Complex multi-metal sulfide ore copper-lead-zinc-arsenic flotation separation method

A separation method and multi-metal technology, applied in the field of metallurgy, can solve the problems of highly toxic environment of cyanide, affecting the quality of concentrate, loss of arsenic resources, etc., and achieve good separation effect, no pollution to the environment, and low dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

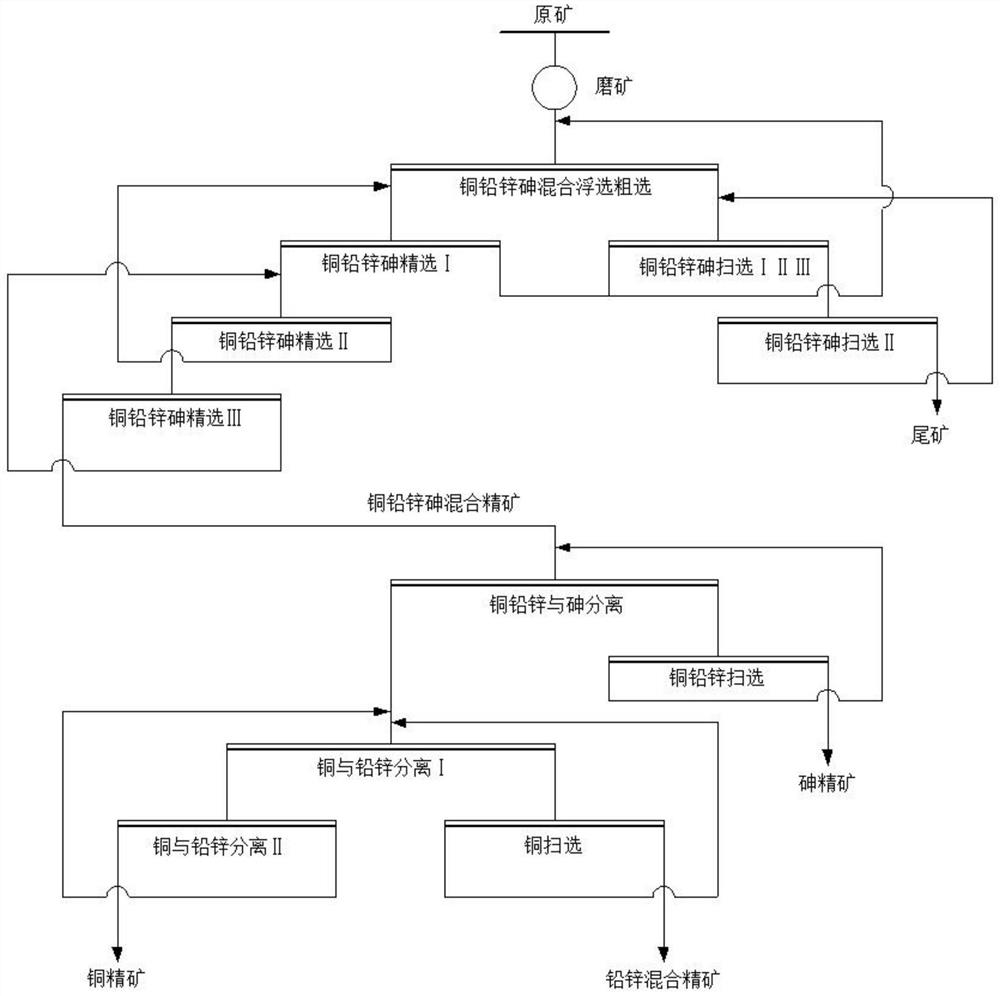

[0030] A method for flotation separation of copper, lead, zinc and arsenic in complex polymetallic sulfide ores, comprising the following steps:

[0031]Step S1: Grinding operation: crush the raw ore, put the crushed raw ore and water into the ball mill for grinding, and the ratio of raw ore and water is 1:1, and the discharge condition of the ball mill is grinding The fineness reaches -0.074mm, accounting for 65%;

[0032] Step S2: Copper, lead, zinc and arsenic mixed flotation operation: add dilute sulfuric acid to the flotation machine to adjust the pH value of the pulp to weak alkaline, use butyl xanthate as a collector and terpineol oil as a foaming agent, and add During the process, after stirring separately, one roughing, three times of beneficiation and two sweeping are carried out to obtain copper, lead, zinc and arsenic mixed concentrate and tailings;

[0033] Step S3: Separation of copper, lead, zinc and arsenic: add sodium sulfide and activated carbon to the mixed...

Embodiment 2

[0042] A method for flotation separation of copper, lead, zinc and arsenic in complex polymetallic sulfide ores, comprising the following steps:

[0043] Step S1: Grinding operation: crush the raw ore, put the crushed raw ore and water into the ball mill for grinding, and the ratio of raw ore and water is 1:1, and the discharge condition of the ball mill is grinding The fineness reaches -0.074mm, accounting for 68%;

[0044] Step S2: Copper, lead, zinc and arsenic mixed flotation operation: add dilute sulfuric acid to the flotation machine to adjust the pH value of the pulp to weak alkaline, use butyl xanthate as a collector and terpineol oil as a foaming agent, and add During the process, after stirring separately, one roughing, three times of beneficiation and two sweeping are carried out to obtain copper, lead, zinc and arsenic mixed concentrate and tailings;

[0045] Step S3: Separation of copper, lead, zinc and arsenic: add sodium sulfide and activated carbon to the mixe...

Embodiment 3

[0054] A method for flotation separation of copper, lead, zinc and arsenic in complex polymetallic sulfide ores, comprising the following steps:

[0055] Step S1: Grinding operation: crush the raw ore, put the crushed raw ore and water into the ball mill for grinding, and the ratio of raw ore and water is 1:1, and the discharge condition of the ball mill is grinding The fineness reaches -0.074mm, accounting for 70%;

[0056] Step S2: Copper, lead, zinc and arsenic mixed flotation operation: add dilute sulfuric acid to the flotation machine to adjust the pH value of the pulp to weak alkaline, use butyl xanthate as a collector and terpineol oil as a foaming agent, and add During the process, after stirring separately, one roughing, three times of beneficiation and two sweeping are carried out to obtain copper, lead, zinc and arsenic mixed concentrate and tailings;

[0057] Step S3: Separation of copper, lead, zinc and arsenic: add sodium sulfide and activated carbon to the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com