Preparation method and application of two-dimensional layered bismuth oxychloride-Fe doped and modified photocatalytic material

A photocatalytic material and two-dimensional layered technology, applied in the field of photocatalysis, can solve the problems of material modification that have not been studied, and achieve excellent degradation effect, simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

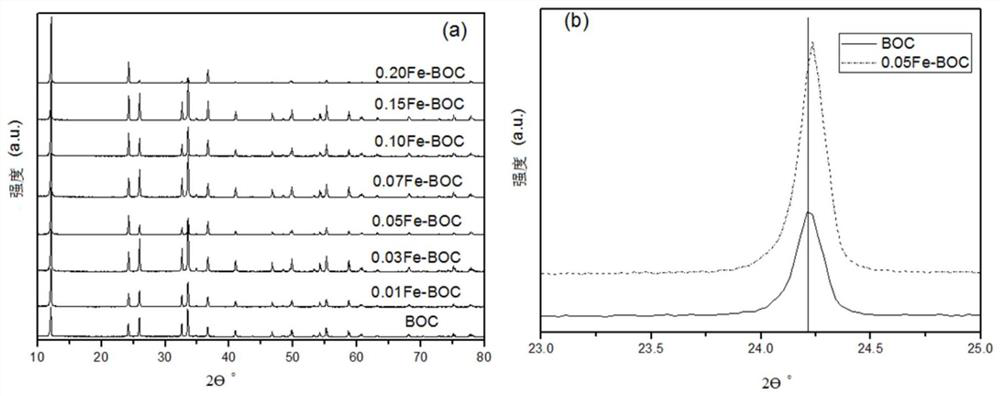

[0033] (1) Fe bulk phase-doped BiOCl was prepared by molten salt method, and 25 g of NaNO with a mass ratio of 1:1 was weighed 3 and KNO 3 Mix and grind, then add 1.9403 g Bi(NO 3 ) 3 • 5H 2 O, 1.0000g KCl and 0.0170 g Fe(NO 3 ) 3 •9(H 2 0), mixed grinding 3h to get mixed powder;

[0034] (2) Place the mixed powder in an alumina crucible, anneal at 400°C for 3 hours, and cool naturally to ambient temperature to obtain a semi-finished product;

[0035] (3) Take out the semi-finished product, then wash it repeatedly with a mixed solution of deionized water and absolute ethanol, and then place the washed semi-finished powder in an oven at 80°C for overnight drying (abbreviated as 0.01Fe-BOC).

Embodiment 2

[0037] (1) Fe bulk phase-doped BiOCl was prepared by molten salt method, and 25 g of NaNO with a mass ratio of 1:1 was weighed 3 and KNO 3 Mix and grind, then add 1.9403 g Bi(NO 3 ) 3 • 5H 2 O, 1.0000g KCl and 0.0511 g Fe(NO 3 ) 3 •9(H 2 O), mixed grinding 3h. .

[0038] (2) Place the mixed powder in an alumina crucible, anneal at 400°C for 3h, and cool naturally to ambient temperature.

[0039] (3) Then wash repeatedly with a mixed solution of deionized water and absolute ethanol. Finally, the semi-finished powder was dried overnight in an oven at 80°C. (abbreviated as 0.03Fe-BOC).

Embodiment 3

[0041] (1) Fe bulk phase-doped BiOCl was prepared by molten salt method, and 25 g of NaNO with a mass ratio of 1:1 was weighed 3 and KNO 3 Mix and grind, then add 1.9403 g Bi(NO 3 ) 3 • 5H 2 O, 1.0000g KCl and 0.0851 g Fe(NO 3 ) 3 •9(H 2 O), mixed grinding 3h.

[0042] (2) Place the mixed powder in an alumina crucible, anneal at 400°C for 3h, and cool naturally to ambient temperature.

[0043] (3) Then wash repeatedly with a mixed solution of deionized water and absolute ethanol. Finally, the semi-finished powder was dried overnight in an oven at 80°C. (abbreviated as 0.05Fe-BOC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com