Flexible tactile sensor array and preparation method thereof

A tactile sensor and tactile sensing technology, which is applied in the direction of instruments, measuring devices, and measuring forces, can solve the problems of resistive flexible tactile sensor range and integration bottleneck, sensitivity, hysteresis, and insufficient integration, etc., to ensure that the array The effect of integration, sensitivity improvement, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

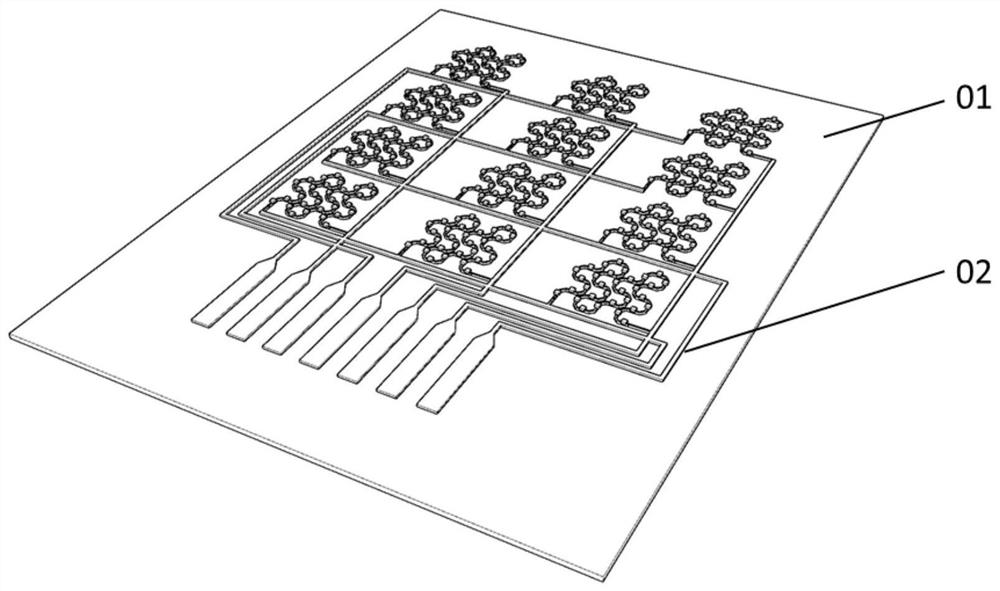

[0047] like figure 1 As shown, a 4×3 flexible tactile sensor array is laminated by a two-layer structure, including a flexible substrate 01 and a tactile sensor array 02 from bottom to top. The tactile sensing array 02 includes 4×3 tactile sensing units and an interconnect network connecting each tactile sensing unit.

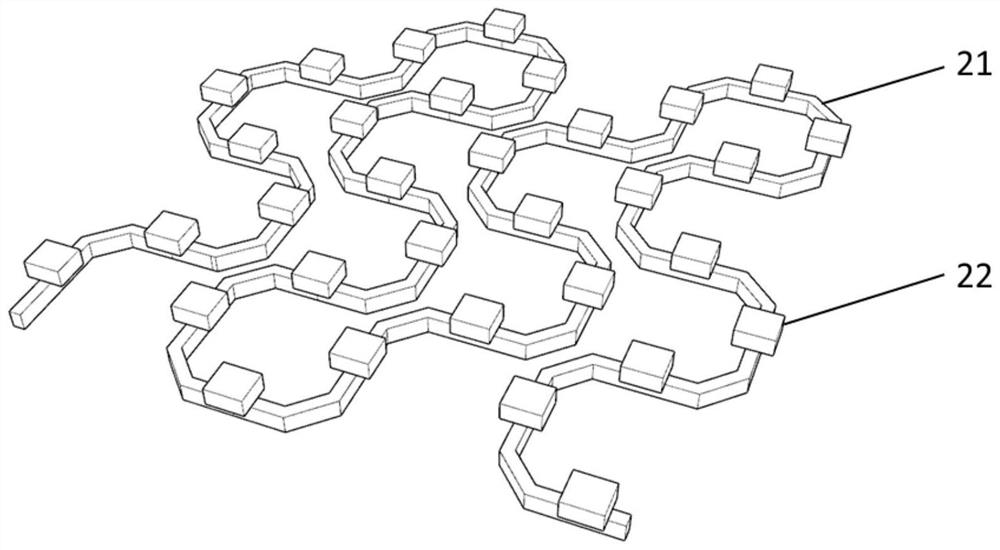

[0048] like figure 2 As shown, the tactile sensing unit is a grid-shaped metal foil 21 wrapped and packaged by a conformal polymer, and a rigid micro-column array 22 is integrated on the grid-shaped metal foil 21 .

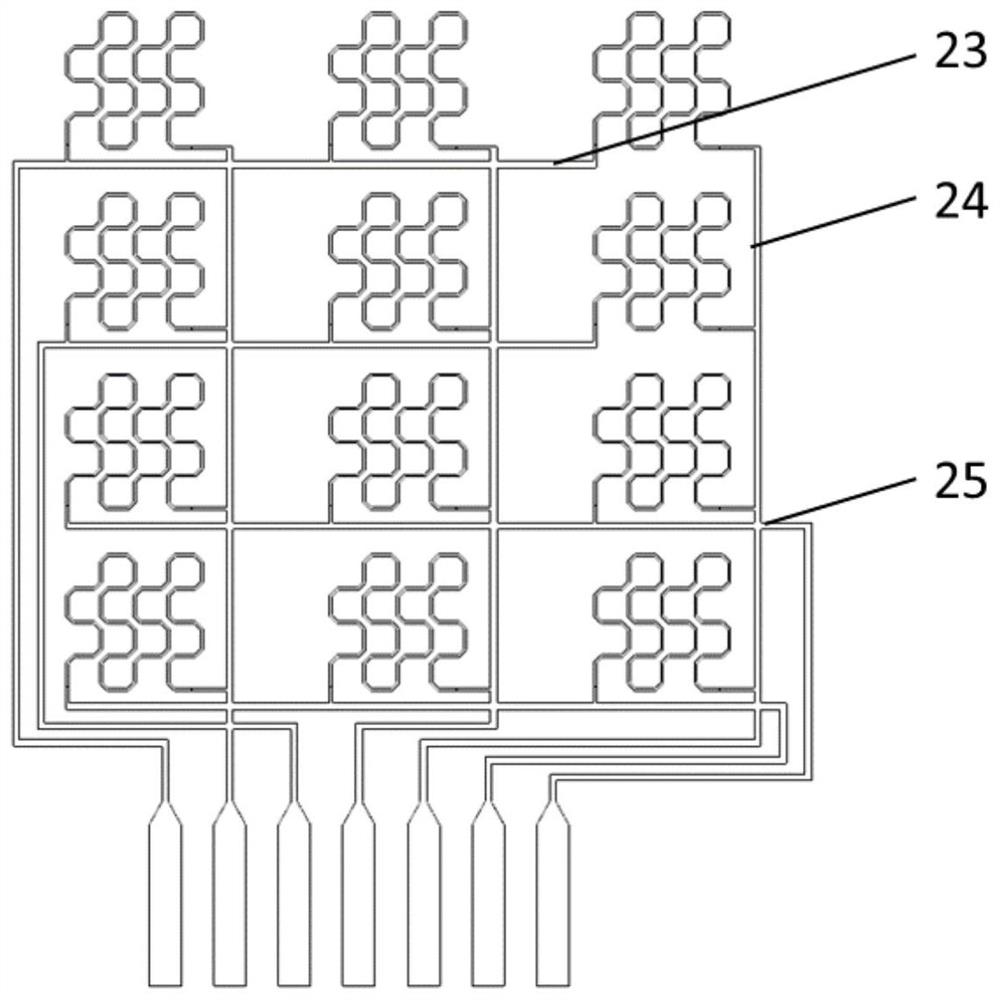

[0049] In order to facilitate the understanding of the interconnection network, such as image 3 As shown, 4×3 grid-shaped metal foils 21 of rectangular wave type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com