T-girder flange slab tensioning joint under post-tensioned bonded prestressed ribbed slab and construction method

A technology of bonding prestressed and prestressed tendons, applied in the direction of floor slabs, joists, girders, etc., can solve the problems of reduced section bearing capacity, difficult construction, high slab surface, etc., to improve the mechanical characteristics and anti-negative bending of nodes Good moment effect and strong shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

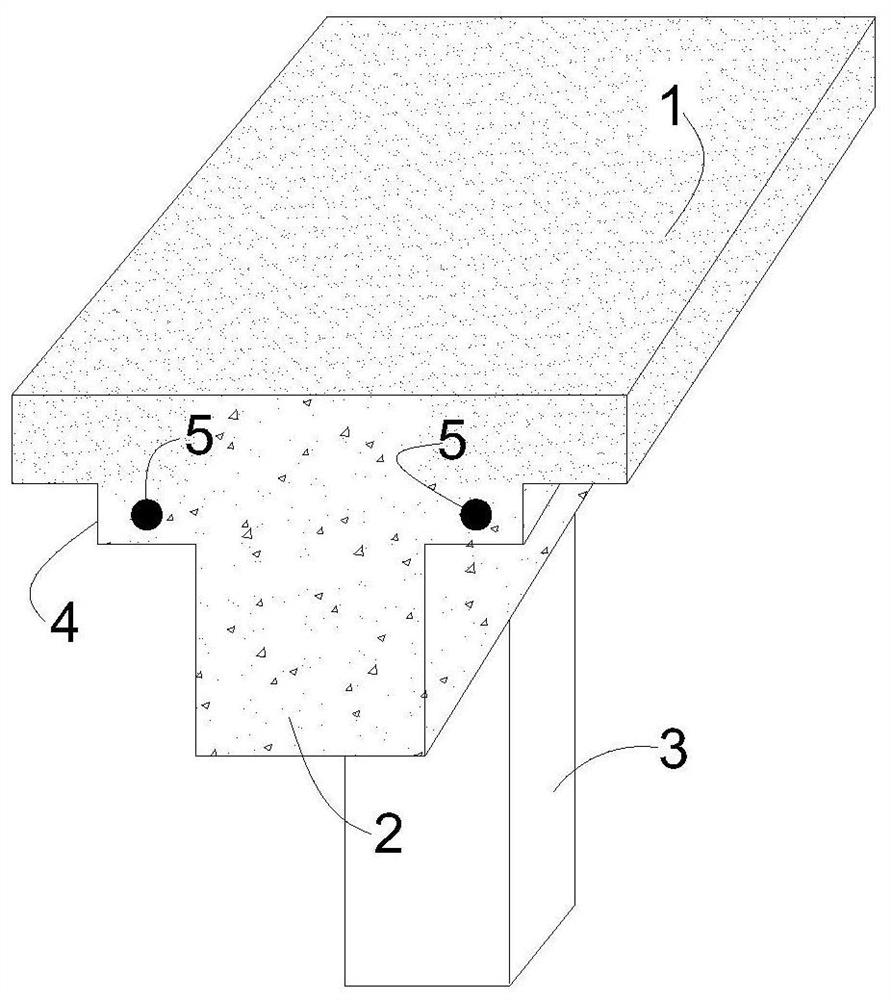

[0033] A post-tensioned T-beam flange tension node structure with bonded prestressed ribs, including a cast-in-place floor 1, a partial cast-in-place T-beam 2, a cast-in-place concrete column 3, and bonded prestressed steel bars 5; The cast-in-place T-beam 2 is arranged at the lower part of the cast-in-place floor 1; the partial cast-in-place T-beam 2 is connected with the cast-in-place concrete column 3; the two ends of the partial cast-in-place T-beam 2 are provided with prestressed tunnels and internal prestressed steel bars 5, The bonded prestressed tendons 5 constitute the tension end nodes of the cast-in-place T beam 2 prestressed tendons in later construction.

[0034] This embodiment effectively realizes the implementation of the new structure and new technology of the prestressed construction of the beam-column joints of the cast-in-place reinforced concrete structure.

[0035] In order to further explain this embodiment, it should be noted that the partial cast-in-pl...

Embodiment 2

[0038] A post-tensioning method has a bonded prestressed rib lower T-beam flange tension node and a construction method, and the specific steps are:

[0039] 1) Cast-in-place concrete column 3 reinforcement binding and formwork installation construction. In order to better complete the installation of the follow-up T-beam wing plate, the installation of the cast-in-place concrete column formwork must be completed first. When the cast-in-place concrete column is installed on site, the installation size of the T-beam wing plate under the follow-up plate must be considered at the top of the column. That is, the thickness of the T-beam wing plate is lowered at the joint of the column-beam joint to realize the effective docking of the installation of the local T-beam wing plate formwork protruding under the subsequent plate. The cast-in-place concrete column formwork adopts aluminum alloy formwork or wood formwork. After the cast-in-place concrete column formwork is installed, do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com