Superhydrophobic daytime passive radiation cooling fabric and preparation method thereof

A radiative refrigeration and superhydrophobic technology, which is applied to plant fibers, textiles, papermaking, coatings, etc., can solve the problems of high cost, complicated preparation methods, and poor cooling performance, and achieve high-efficiency radiative refrigeration, simple preparation process, and excellent performance. Effect of spectrally selective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

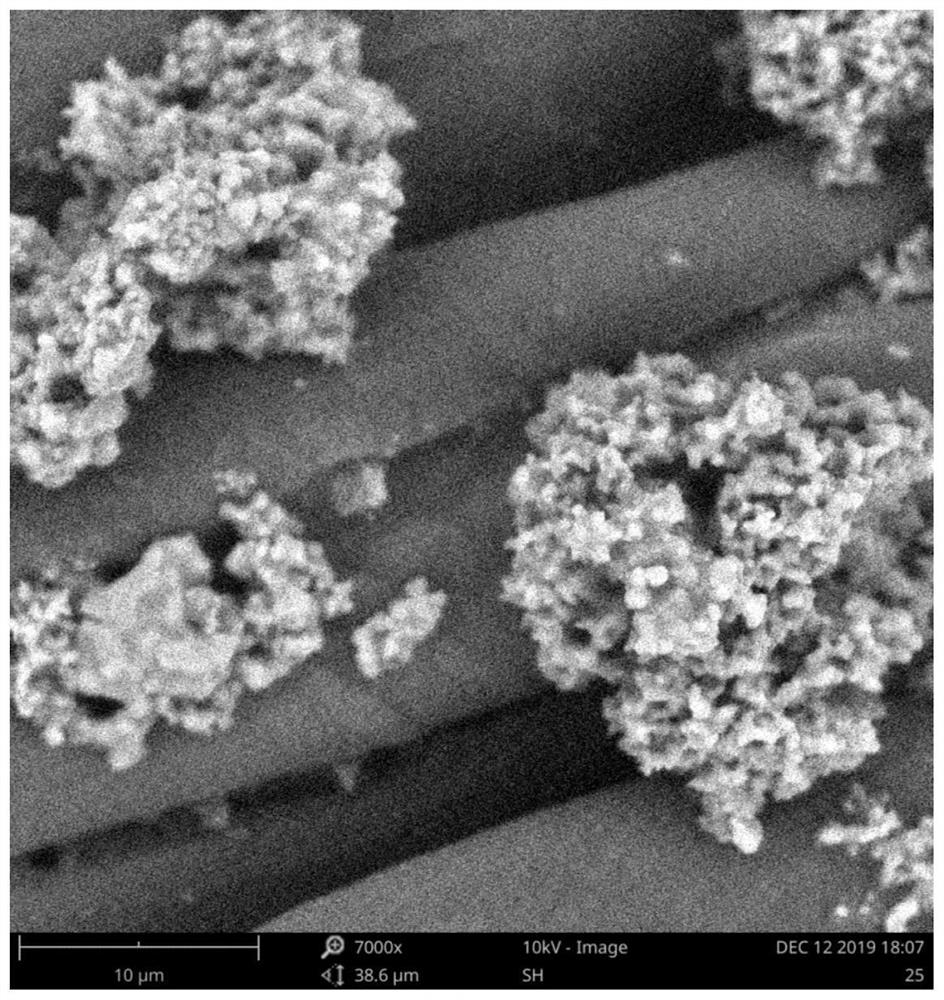

[0055] (1) The mass fraction of the aluminum phosphate aqueous dispersion was prepared to be 1.0 wt%. At this time, 0.50 g of the above-mentioned aluminum phosphate radiation particles were weighed and dispersed in deionized water by magnetic stirring to form a 50 g aluminum phosphate aqueous dispersion. Then add 0.01 g of silane coupling agent KH550, and stir magnetically at room temperature for 24 hours to obtain the daytime passive radiation cooling radiation particle functional coating required for the preparation of spectrally selective reflection / radiation coating.

[0056] (2) According to the polymer mass ratio of the superhydrophobic coating, 3g of PDMS polymer was weighed and dissolved in 30mL THF solution, and ultrasonically dispersed to obtain the superhydrophobic polymer functional coating required for the preparation of the superhydrophobic coating.

[0057] (3) The above-mentioned daytime passive radiation spectrum selective coating and superhydrophobic coating a...

Embodiment 2

[0059] (1) The mass fraction of the aluminum phosphate aqueous dispersion was prepared to be 2.0 wt%, and 1.0 g of the above-mentioned aluminum phosphate radiation particles were weighed and dispersed in deionized water by magnetic stirring to form 50 g of the aluminum phosphate aqueous dispersion. Then add 0.02 g of silane coupling agent KH550, and stir magnetically at room temperature for 24 hours to obtain the daytime passive radiation cooling radiation particle functional coating required for the preparation of spectrally selective reflection / radiation coating.

[0060] (2) According to the polymer mass ratio of the superhydrophobic coating, 3g of PDMS polymer was weighed and dissolved in 30mL THF solution, and ultrasonically dispersed to obtain the superhydrophobic polymer functional coating required for the preparation of the superhydrophobic coating.

[0061] (3) On the surface of ordinary cotton fabrics, the daytime passive radiation spectrum selective coating and the s...

Embodiment 3

[0063] (1) The mass fraction of aluminum phosphate aqueous dispersion was prepared to be 3.0 wt%. 1.5 g of the above-mentioned aluminum phosphate radiation particles were weighed and dispersed in deionized water by magnetic stirring to form 50 g of aluminum phosphate aqueous dispersion. Then add 0.03 g of silane coupling agent KH550, and stir magnetically at room temperature for 24 hours to obtain the daytime passive radiation cooling radiation particle functional coating required for the preparation of spectrally selective reflection / radiation coating.

[0064] (2) According to the polymer mass ratio of the superhydrophobic coating, 3g of PDMS polymer was weighed and dissolved in 30mL THF solution, and ultrasonically dispersed to obtain the superhydrophobic polymer functional coating required for the preparation of the superhydrophobic coating.

[0065] (3) On the surface of ordinary cotton fabrics, the daytime passive radiation spectrum selective coating and the superhydropho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com