A heat treatment device for the production of copper plate sliders with graphite pores

A heat treatment device and slider technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of cooling treatment of copper plate sliders that cannot have graphite pores, and copper plate slider fractures, etc., to improve sufficiency and avoid fracture damage. , the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

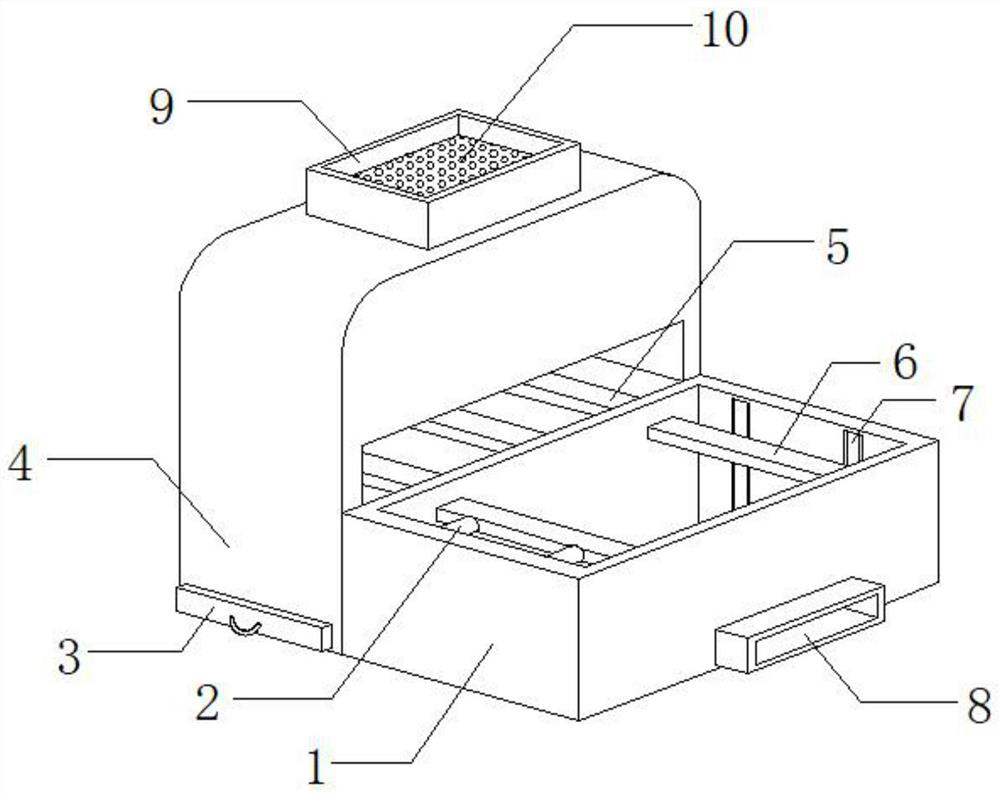

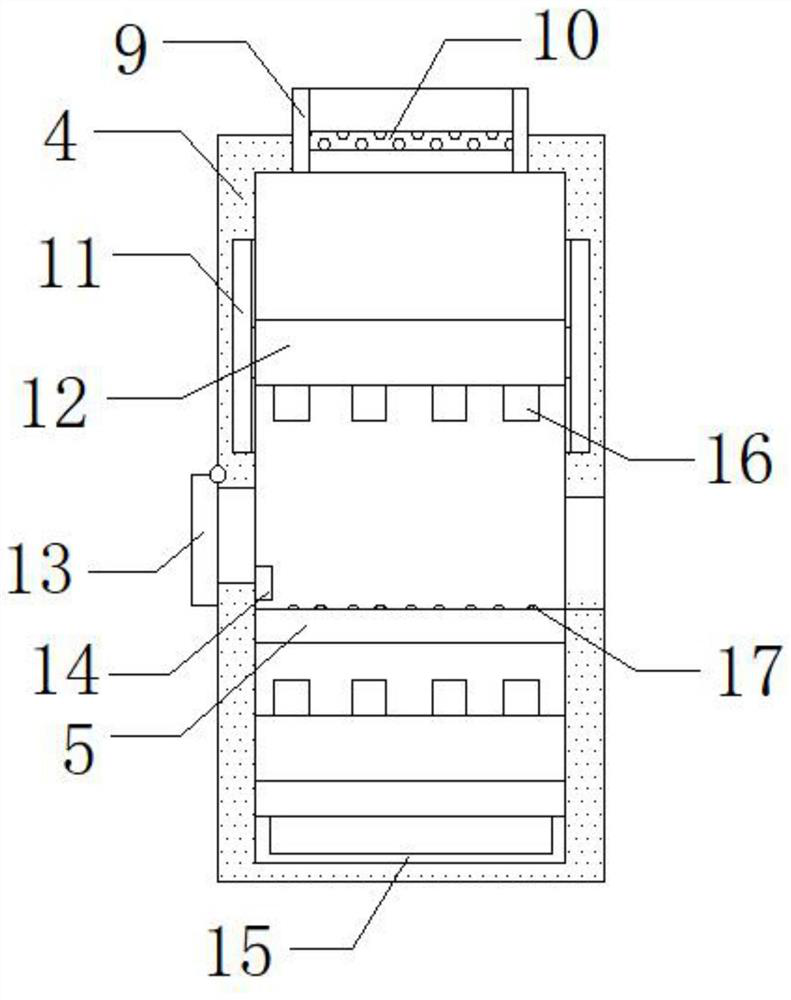

[0024] refer to Figure 1-3 , a heat treatment device for producing a copper plate slider with graphite pores, comprising a combustion box 4, the bottom outer wall of one side of the combustion box 4 is connected with a reservoir 1 by bolts, and the inner walls on both sides of the reservoir 1 are both There are first grooves, the inner walls of the four first grooves are connected with the first electric guide rails 7 arranged vertically through bolts, and the outer walls of the adjacent ends of the four first electric guide rails 7 are slidably connected with the first electric sliding rails. The outer walls of the adjacent ends of the four first electric sliders are connected with electric telescopic rods 2 by bolts, and the outer walls of one end of the two electric telescopic rods 2 located at the same end are connected with the same second support plate 6 by bolts. The inner walls of the top on both sides of the body 4 are provided with second grooves, and the inner wall...

Embodiment 2

[0029] refer to Figure 1-4 , a heat treatment device for producing a copper plate slider with graphite pores, further comprising support rods 19 that are installed vertically on the outer walls of the four corners of the top of the reservoir 1 by bolts, and the top outer walls of the four support rods 19 are bolted. One supports the top plate 20 .

[0030]Working principle: when the copper plate slider is cooled, the setting of the supporting top plate 20 can effectively avoid the harm to the user caused by the flue gas generated during the cooling process, and the supporting top plate 20 can effectively cool the flue gas by partitions, and further. The safety of using the device is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com