Adhesive for drawing slot wedge, and preparation method of slot wedge using adhesive

An adhesive and slot wedge technology, applied in polymer adhesive additives, using/manufacturing slot locking devices, adhesive additives, etc., can solve problems such as poor mechanical strength, achieve high heat resistance, and excellent mechanical properties. , the effect of good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0032] In embodiment 1~5, the preparation method of the epoxy resin of bismaleimide modification is:

[0033] 1) Put 90 parts of E51 epoxy resin, 10 parts of 638 epoxy resin and 5 parts of maleic anhydride into the reaction kettle in sequence, and keep warm at 130±5°C until the acid value is less than 3mgKOH / g;

[0034] 2) After the acid value is qualified, add 15 parts of bismaleimide, keep warm at 145±5°C until the liquid surface is clear and transparent, then cool down, add 10 parts of vinyl toluene, and obtain bismaleimide modified epoxy resin.

Embodiment 1

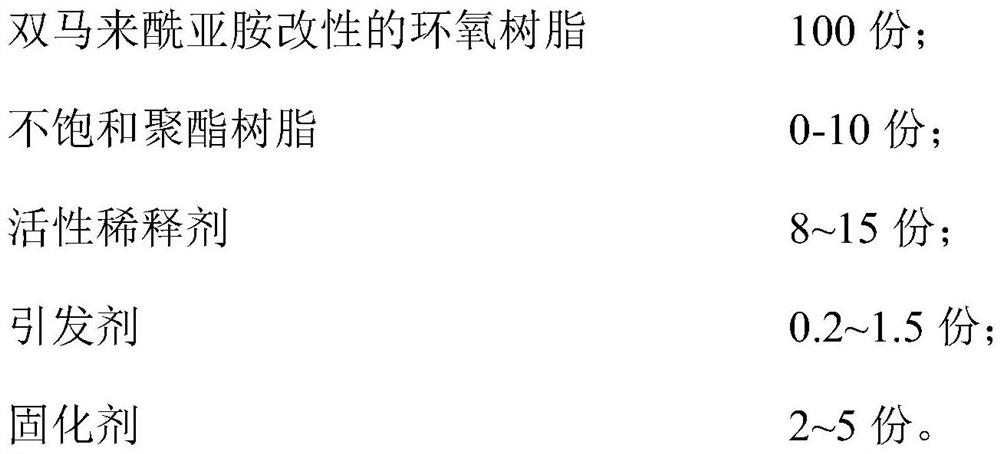

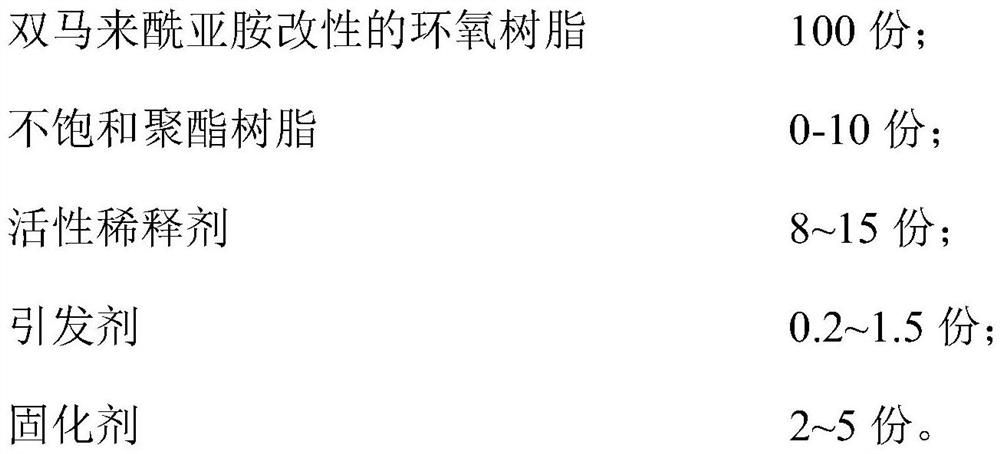

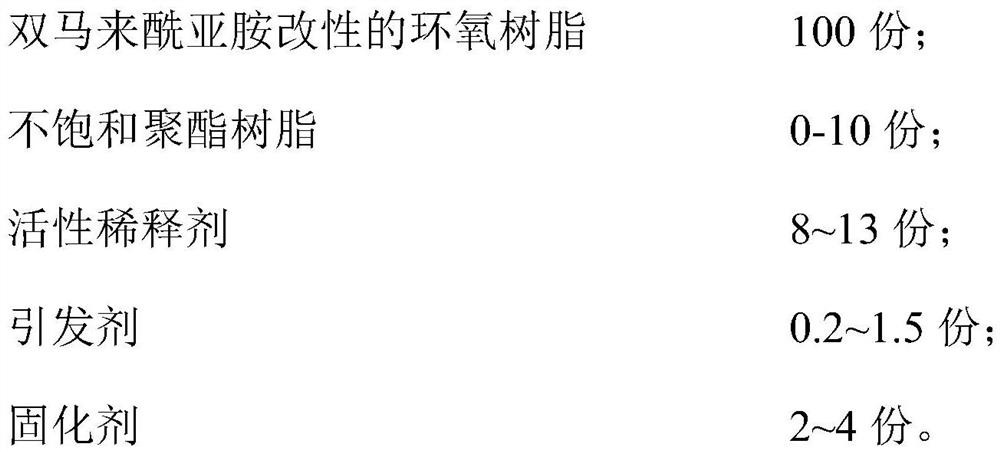

[0038] The formula of the adhesive of the present embodiment is:

[0039] Bismaleimide modified epoxy resin 100g, initiator dicumyl peroxide (DCP) 1.5g, reactive diluent are styrene 13g, curing agent is 2-ethyl-4 methylimidazole 4.0g .

[0040] After the above-mentioned components are mixed evenly according to the formula, the high heat-resistant and high-strength epoxy adhesive for drawing and pulling is prepared. When the adhesive is used, the mold is heated to 160°C in the curing step, and the resin stays in the mold for 80 seconds. After the curing step at high temperature, an insulating material is formed, and the insulating material is obtained through a subsequent process to obtain a slot wedge.

Embodiment 2

[0042] The formula of the adhesive of the present embodiment is:

[0043] Bismaleimide modified epoxy resin 100g, isophthalic unsaturated polyester resin 6g, tert-butyl peroxybenzoate 1.0g, reactive diluent is styrene 10g, curing agent 2-ethyl-4 Methylimidazole 3.0g.

[0044] After the above-mentioned components are mixed evenly according to the formula, the adhesive for high temperature resistant slot wedge is prepared. When the adhesive is used, the mold is heated to 150°C in the curing step, and the resin stays in the mold for 80 seconds. After the curing step at high temperature, an insulating material is formed, and the insulating material is obtained through a subsequent process to obtain a slot wedge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com