Water-based pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, water-based technology, applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc., can solve the problems of incomplete resin polymerization, environmental pollution, waste of raw materials, etc., to avoid sticking The effects of joint failure, waste reduction, and not easy degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

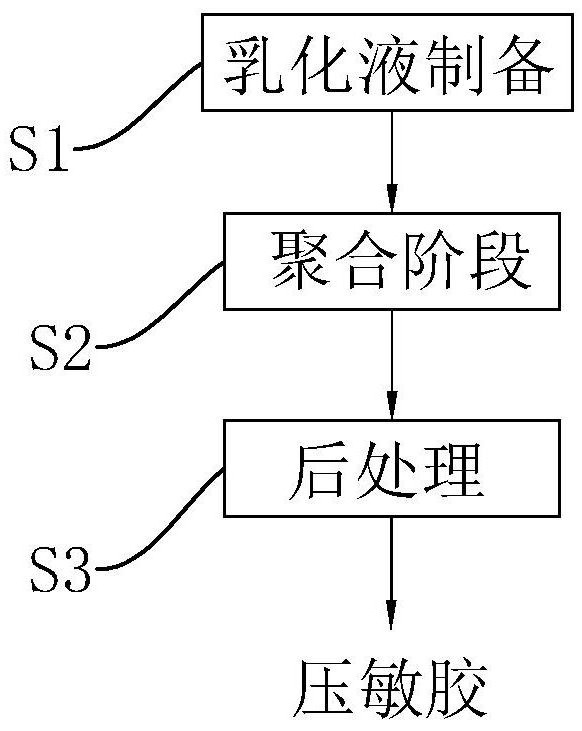

[0036] refer to figure 1 , a method for preparing a water-based pressure-sensitive adhesive, comprising the following steps: all the following substances are in parts by weight;

[0037]S1: Preparation of emulsion. Add 20 parts of deionized water into the first reaction vessel, which is an emulsification tank, and start stirring, then add 4 parts of emulsifier, the emulsifier is isooctyl phosphate, and then continue to stir until emulsification After the materials in the kettle are dissolved, add 0.5 parts of oily initiator, 40 parts of butyl acrylate, 8 parts of acrylate compounds and 11 parts of isooctyl acrylate. The oily initiator is BPO, and continue to stir until the material is milky white and emulsified liquid, spare. The acrylate compound includes hydroxyethyl acrylate and acrylic acid, and the weight ratio of the two is 1:1.

[0038] S2: Aggregation stage. Add 20 parts of deionized water into the second reaction vessel, the second reaction vessel is a reaction ke...

Embodiment 2

[0042] A method for preparing a water-based pressure-sensitive adhesive, comprising the following steps: all the following substances are in parts by weight;

[0043] S1: Preparation of emulsion. Add 20 parts of deionized water into the first reaction vessel, which is an emulsification tank, and start stirring, then add 4 parts of emulsifier, the emulsifier is isooctyl phosphate, and then continue to stir until emulsification After the materials in the kettle are dissolved, add 0.5 parts of oily initiator, 40 parts of butyl acrylate, 8 parts of acrylate compounds, 11 parts of isooctyl acrylate, 0.3 parts of magnesium aluminum silicate and 0.5 parts of cyclohexasiloxane alkane, the oily initiator is cuprous naphthalate, and the stirring is continued until the material in the emulsification tank is milky white to obtain an emulsion, which is set aside. The acrylate compound includes hydroxyethyl acrylate and acrylic acid, and the weight ratio of the two is 1:1.

[0044] S2: Ag...

Embodiment 11

[0052] The difference between Example 11 and Example 1 is that the oily initiators are naphthenates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com