Method for continuously treating electrolytic manganese wastewater to recover manganese and ammonia nitrogen resources

A technology of electrolytic manganese and wastewater, which is applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems that manganese and ammonia nitrogen cannot be recovered separately, and have not been applied in large-scale industrialization, so as to reduce work intensity, Easy operation and management, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

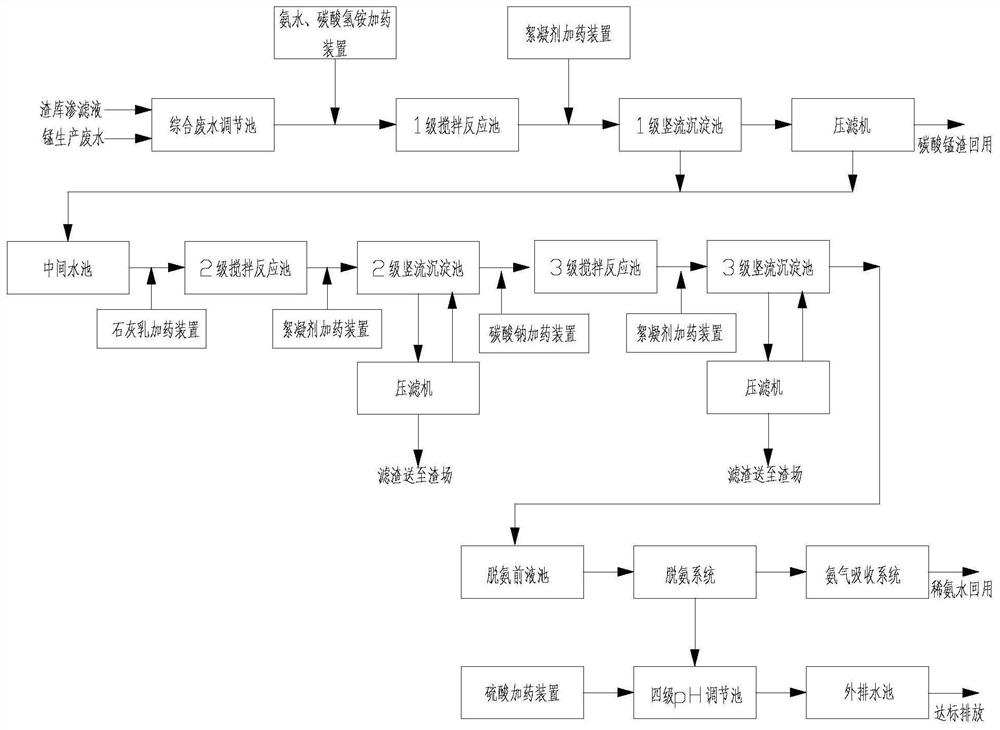

Image

Examples

Embodiment 1

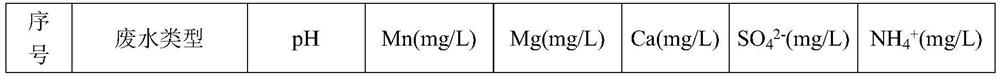

[0048] The invention has been technically transformed in an electrolytic manganese factory in Guizhou, and put into operation. It has been successfully applied in industrial production, and the production runs well. In this example, the waste water and leachate of a slag reservoir in an electrolytic manganese workshop in Guizhou were taken as examples, and the analysis results of the waste water are shown in Table 1.

[0049] Table 1: Analysis results of electrolytic manganese wastewater (%)

[0050]

[0051]

[0052] The continuous method for reclaiming manganese and ammonia nitrogen resources from the electrolytic manganese workshop wastewater and the electrolytic manganese slag warehouse wastewater of the present embodiment comprises the following steps:

[0053] (1) Wastewater collection: collect the electrolytic manganese slag reservoir leachate Mn content of 14000mg / l and electrolytic manganese production wastewater Mn content of 4000mg / l in the collection pool and...

Embodiment 2

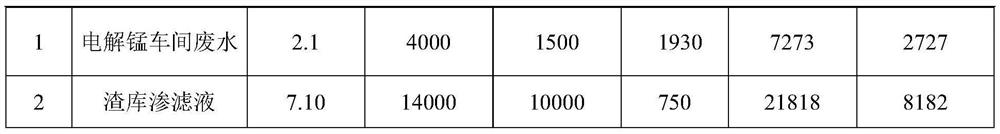

[0064] In this example, wastewater from an electrolytic manganese workshop in Guizhou and leachate from a slag reservoir were taken as examples, and the analysis results of wastewater are shown in Table 2.

[0065] Table 2: Analysis results of electrolytic manganese wastewater (%)

[0066]

[0067] The operation steps and control parameters of the second embodiment are consistent with those of the first embodiment.

[0068] In this example, the waste water collection is mainly to collect the Mn content of the electrolytic manganese slag reservoir leachate with a Mn content of 9770mg / l and the electrolytic manganese production wastewater with a Mn content of 1826mg / l in the collection pool and fully mix them to stabilize the water quality fluctuation of the raw water;

[0069] In this instance, the manganese carbonate slag manganese content of sedimentation pressure filtration gained reaches 40%, carries out X-ray diffraction analysis to manganese carbonate slag, and the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com