Lithium metal composite negative electrode with lithium-philic and lithium-phobic gradient structure, and preparation method thereof

A gradient structure, lithium metal technology, applied in negative electrodes, structural parts, battery electrodes, etc., can solve problems such as low Coulombic efficiency, affecting battery cycle efficiency, pulverization, etc., to improve Coulombic efficiency, improve cycle stability, ease The effect of electrode pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

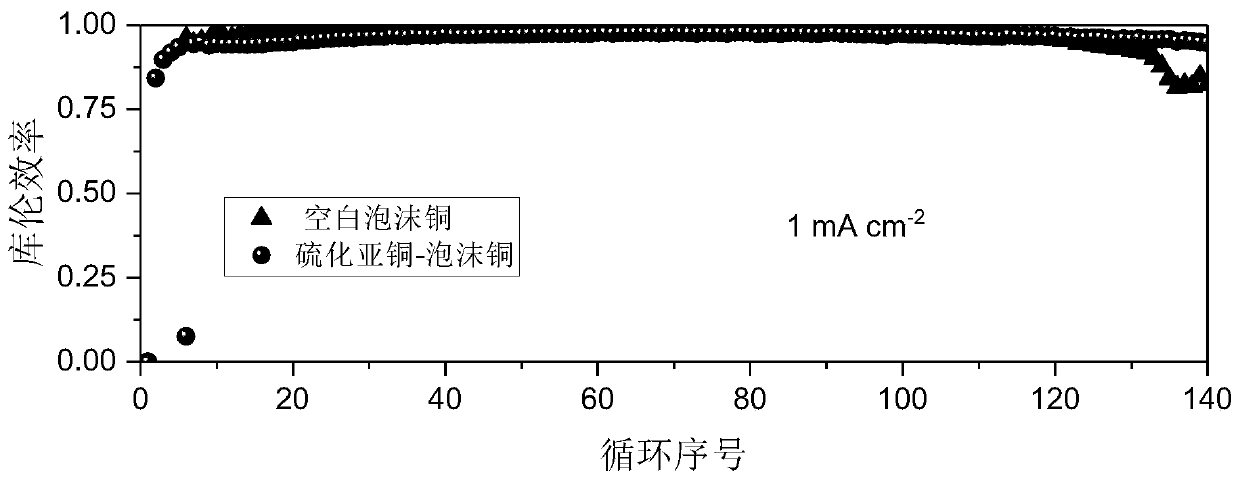

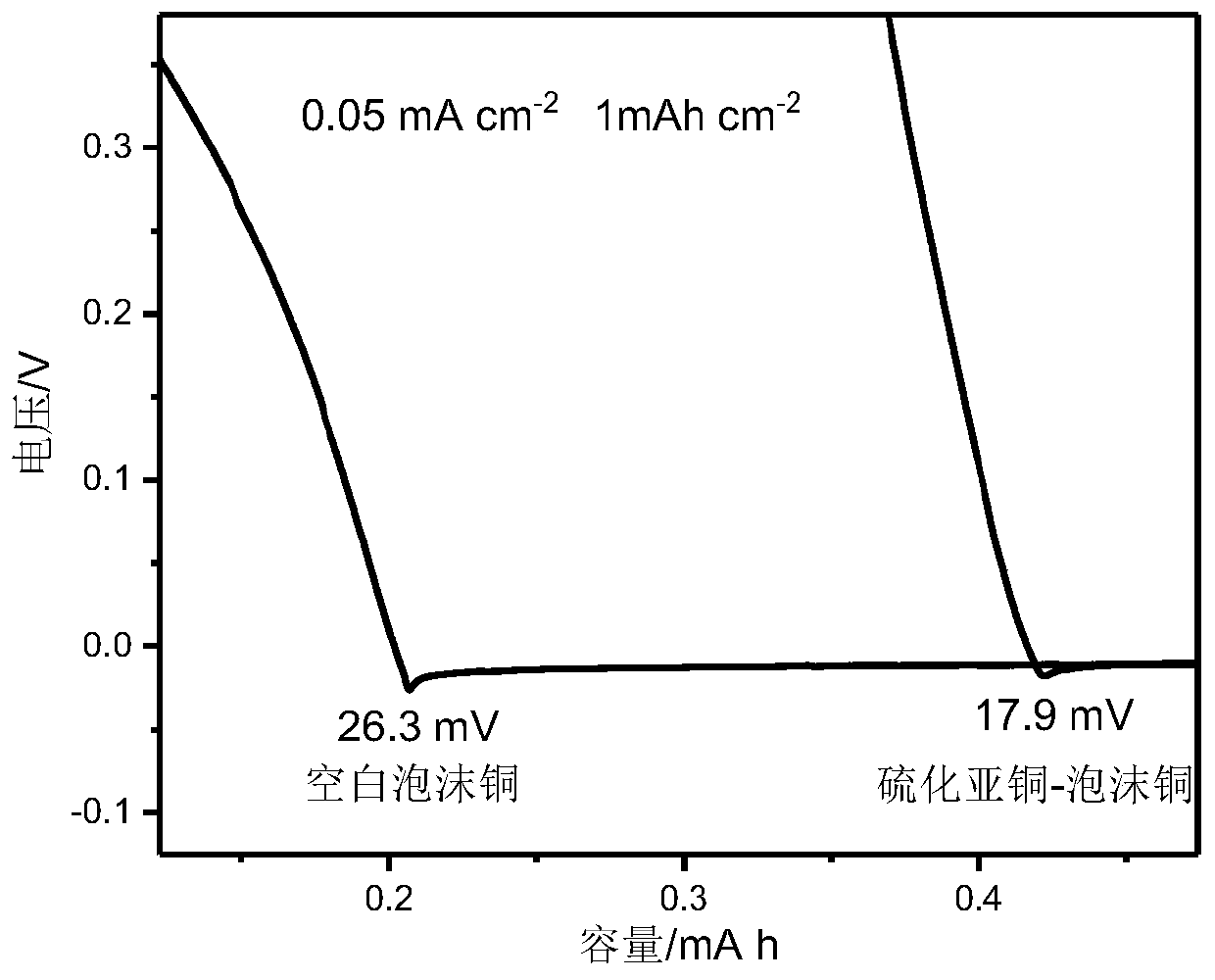

Embodiment 1

[0041] A kind of preparation method of cuprous sulfide-foam copper-lithium metal composite negative electrode through lithiophilic modification, comprises the following steps:

[0042] (1) Cut the commercial copper foam into a rectangular piece of 4cm*5 cm, soak it in absolute ethanol, and ultrasonicate for 15 minutes to remove the grease impurities on the surface; then, immerse the foam copper after the first cleaning in the pre-washed In the prepared 1 M dilute hydrochloric acid solution, ultrasonic for 15 minutes to remove surface oxides; finally, ultrasonic cleaning with water for 15 minutes to remove residual hydrochloric acid on the surface of foamed copper. Blow dry in a nitrogen atmosphere and set aside;

[0043] (2) Accurately weigh 0.0210 g of thioacetamide (TAA) and 0.0490 g of tin tetrachloride pentahydrate (SnCl4 ·5H 2 O) In a conical flask, measure 70.0mL of polyethylene glycol 400 (PEG400) in the conical flask, stir magnetically for 10 minutes, heat in an oil b...

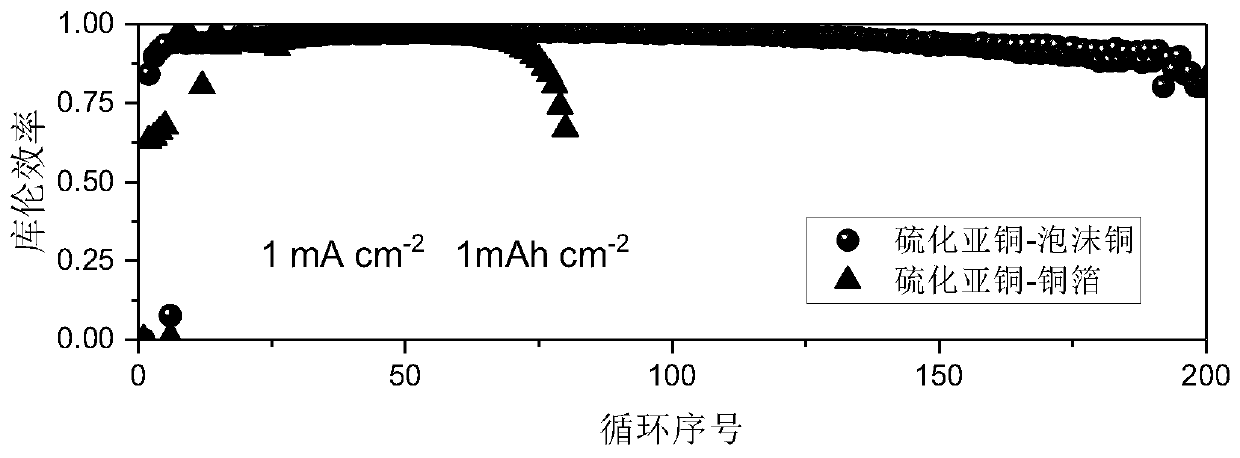

Embodiment 2

[0046] In view of the fact that Example 1 compares the difference between modifying the lithiophilic layer and not modifying the lithiophilic layer on the same foamed copper matrix skeleton, this embodiment studies the two-dimensional matrix (cuprous sulfide-copper foil) skeleton and the three-dimensional matrix skeleton (sulfurized Cuprous - copper foam) for the difference in the negative electrode. The preparation method comprises the following steps:

[0047] (1) take the method same as embodiment 1 to clean copper foil and copper foam;

[0048] (2) Prepare the same precursor solution as in Example 1, and transfer the solution to a reaction kettle lined with polytetrafluoroethylene;

[0049] (3) Put the pretreated copper foam or copper foil vertically into the precursor solution, transfer it to a muffle furnace, heat it up to 180 °C at 10 °C / min, keep it for 15 h, and cool naturally to obtain the same lithium-ophilic modification Two-dimensional cuprous sulfide-copper foi...

Embodiment 3

[0053] In this embodiment, a three-dimensional porous matrix framework (foamed nickel), a lithium-philic layer (Ni 3 S 2 Nanosheet structure) and lithium-phobic layer (multi-walled carbon nanotubes) were combined to prepare a lithium-metal composite anode with a lithium-phobic gradient structure. Include the following steps:

[0054] (1) Cut the commercial nickel foam into rectangular pieces of 4cm*5 cm, soak in absolute ethanol, and ultrasonicate for 15 minutes to remove the grease impurities on the surface; then, immerse the foam nickel after the first cleaning in the pre-washed In the prepared 2 M dilute hydrochloric acid solution, sonicate for 15 minutes to remove surface oxides; finally, ultrasonically clean with water for 15 minutes to remove residual hydrochloric acid on the surface of foamed nickel. Transfer the cleaned foamed nickel to a watch glass and place it in a fume hood for 8 hours, let it dry naturally, and set aside;

[0055] (2) Weigh 0.63 g of Na 2 S 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com