A kind of superabsorbent airgel packaging material prepared by using reed waste residue and its preparation method

A technology of high water absorption and packaging materials, which is applied in the field of food packaging materials, can solve the problems of insufficient water absorption and degradability, and achieve the effects of reducing extraction costs, enhancing water absorption, and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

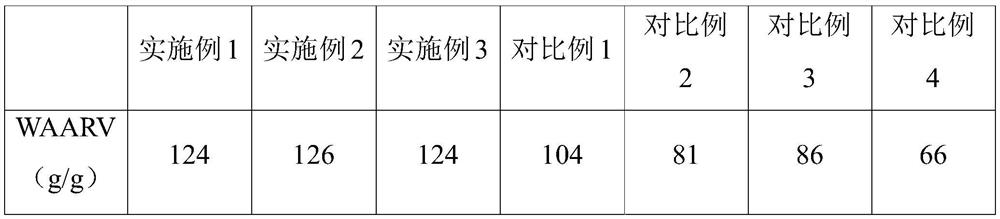

Examples

Embodiment 1

[0029] A method for preparing highly absorbent aerogel packaging material using reed waste residue, comprising the following steps:

[0030] (1) After crushing the reed waste residue, soaking in sodium hydroxide solution with a liquid-solid ratio of 5mL / g for 8h, boiling for 5h, filtering, collecting and cleaning the solid phase products;

[0031] (2) The solid phase product obtained in step (1) is placed in a mixture of lactic acid and betaine with a molar ratio of 0.5:1, stirred evenly at 60 °C, let stand for 5h and filtered, and the solid product is collected;

[0032] (3) After grinding the product obtained in step (2) under the condition of 1000 rpm for 30 min, heat it at 60 °C for 2h;

[0033] (4) At 100 °C, the starch-acrylic graft copolymer and trisodium phosphate were stirred and mixed for 5h in the ratio of 1:1 by weight, cooled to 60 °C, added to the product obtained in step (3), and continued to stir for 6h; The weight ratio of the resulting product to phosphate in ste...

Embodiment 2

[0036] A method for preparing highly absorbent aerogel packaging material using reed waste residue, comprising the following steps:

[0037] (1) After crushing the reed waste residue, soaking in sodium hydroxide solution with a liquid-solid ratio of 8mL / g for 8h, boiling for 5h, filtering, collecting and cleaning the solid phase products;

[0038] (2) The solid phase product obtained in step (1) was placed in a mixture of lactic acid and betaine with a molar ratio of 1:1, stirred evenly at 70 °C, let stand for 6h and filtered, and the solid product was collected;

[0039] (3) After the product obtained in step (2) is ground under the condition of 500 rpm for 20 min, it is heated at 65 °C for 5 h;

[0040] (4) At 120 °C, the starch-acrylic graft copolymer and sodium phosphate were stirred and mixed for 5h in the ratio of 1:3 by weight, cooled down to 65 °C, added to the product obtained in step (3), and continued to stir for 2~6h; The weight ratio of the resulting product to phosphat...

Embodiment 3

[0043] A method for preparing highly absorbent aerogel packaging material using reed waste residue, comprising the following steps:

[0044] (1) After crushing the reed waste residue, soak the solid phase products in a liquid-solid ratio of 10mL / g in a liquid-solid ratio of 10mL / g in sodium hydroxide solution with a concentration of 3mol / L, boil for 5h, filter, collect and clean the solid phase products;

[0045] (2) The solid phase product obtained in step (1) was placed in a mixture of lactic acid and betaine with a molar ratio of 1:1, stirred evenly at 75 °C, let stand for 10h and filtered to collect the solid product;

[0046] (3) After grinding the product obtained in step (2) under the condition of 600 rpm for 30 min, heat it at 75 °C for 3 h;

[0047] (4) At 150 °C, the starch-acrylic graft copolymer and sodium dihydrogen phosphate were stirred and mixed for 3h in the proportion of 1:4 by weight, cooled down to 75 °C, added to the product obtained in step (3), and continued...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com