A high-strength water-permeable stone slab and its preparation method

A color stone board, high-strength technology, applied in the field of building materials, can solve the problems of affecting the appearance of the surface layer, long construction interval, fading, etc., to achieve the effect of improving the uniformity of the package, ensuring the strength and development, and increasing the turnover speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

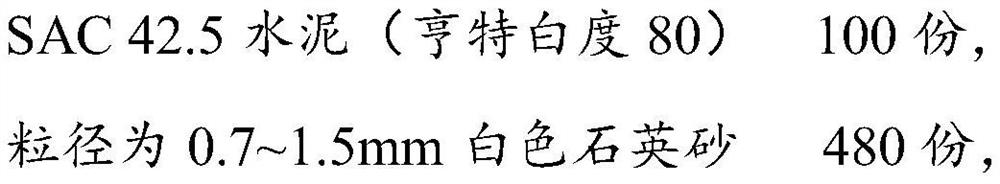

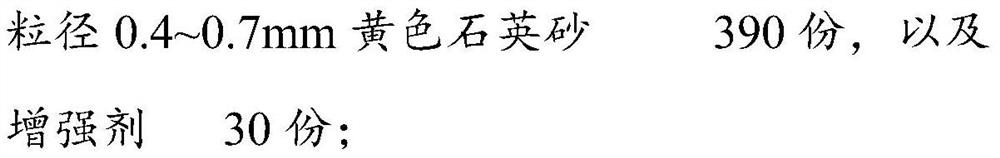

[0032] This embodiment provides a high-strength water-permeable stone slab, which is made by mixing and pressing various raw materials. The raw materials include:

[0033]

[0034] Among them, the reinforcing agent is composed of the following raw materials in parts by weight: limestone powder, vitrified beads, mineral powder, thickener, powder polycarboxylate water reducer, coagulation regulator and quartz sand in a weight ratio of 1:0.2:0.5 :0.02:0.3:0.3:1 composition. The fineness of limestone powder is 400 mesh, the fineness of vitrified microbeads is 80-120 mesh, and the specific surface area of mineral powder is 520m 2 / kg, the thickener is Longhu Technology LH~02 type cellulose ether, the viscosity is 40000mPa·s, the powder polycarboxylate superplasticizer is Longtao Building Materials P160 water reducer, the water reducing rate is 30%, and the coagulation regulator is Commercially available sodium gluconate and lithium carbonate are compounded at a weight ratio o...

Embodiment 2

[0040] This embodiment provides a high-strength water-permeable stone slab, which is made by mixing and pressing various raw materials. The raw materials include:

[0041]

[0042]

[0043] Among them, the reinforcing agent is composed of the following raw materials in parts by weight: limestone powder, vitrified beads, mineral powder, thickener, powder polycarboxylate water reducer, coagulation regulator and quartz sand in a weight ratio of 1:0.2:0.4 :0.01:0.4:0.3:1 composition. The fineness of limestone powder is 400 mesh, the fineness of vitrified microbeads is 80-120 mesh, and the specific surface area of mineral powder is 520m 2 / kg, the thickener is Lotte Chemical MHS30007 cellulose ether, the viscosity is 30000mPa s, the powder polycarboxylate superplasticizer is Longhu Technology P29 water reducer, the water reducing rate is 32%, and the coagulation agent is commercially available glucose Sodium bicarbonate and lithium carbonate are compounded according to the...

Embodiment 3

[0049] This embodiment provides a high-strength water-permeable stone slab, which is made by mixing and pressing various raw materials. The raw materials include:

[0050]

[0051] The reinforcing agent is composed of the following raw materials in parts by weight: limestone powder, vitrified beads, mineral powder, thickener, powder polycarboxylate water reducer, coagulation regulator and quartz sand in a weight ratio of 0.8:0.2:0.6: 0.02:0.3:0.4:1 composition.

[0052] Among them, the fineness of limestone powder in this embodiment is 400 mesh, the fineness of vitrified microbead is 80~120 mesh, and the specific surface area of mineral powder is 520m 2 / kg, the thickener is Dow HPMC75000S cellulose ether, the viscosity is 75000mPa s, the powder polycarboxylate water reducer is BASF-2651F water reducer, the water reducing rate is 35%, and the coagulation agent is commercially available glucose Sodium bicarbonate and lithium carbonate are compounded according to the weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com