Magnesium aluminosilicate nanocrystalline transparent ceramic and preparation method and product thereof

A magnesium aluminum silicate and transparent ceramic technology, which is applied in the chemical industry, can solve the problems of difficult processing, poor plastic material properties, and high ceramic cost, and achieve the effect of improving mechanical strength, strength, fracture toughness, and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

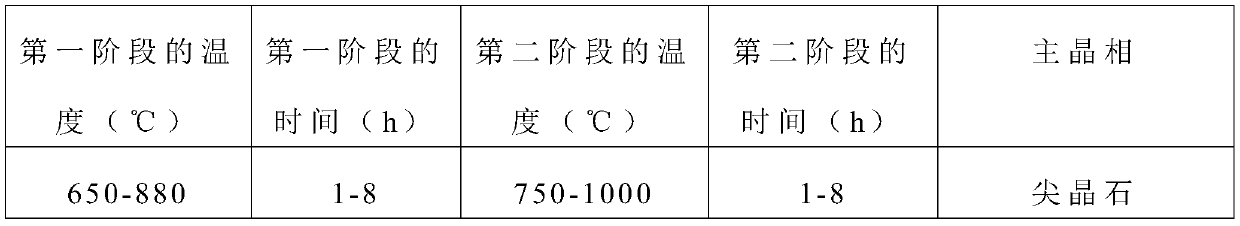

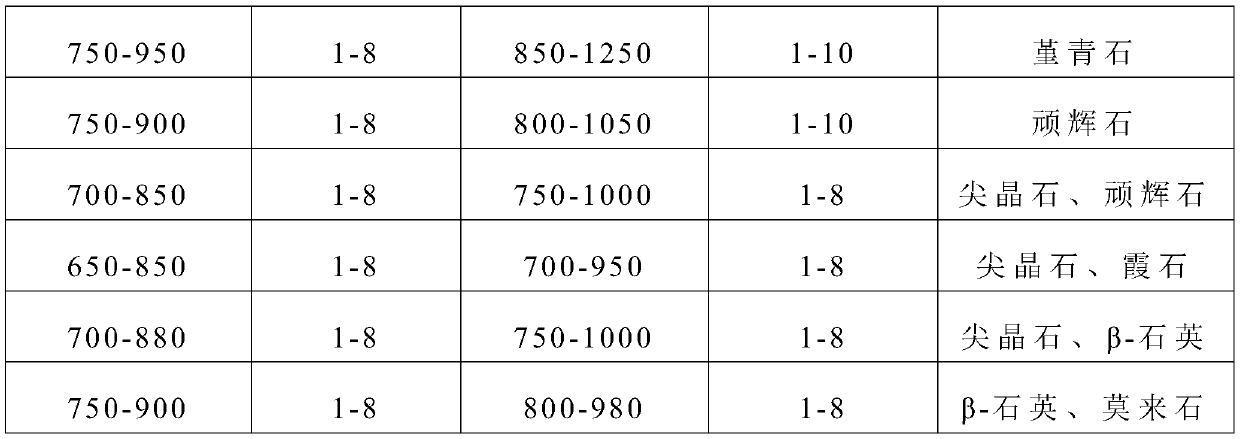

[0051] The present application also provides a preparation method of the magnesium aluminum silicate nanocrystalline transparent ceramic, comprising the following steps:

[0052] Step S1: mixing the above raw materials in proportion and placing them in a reaction kettle, melting the mixed raw materials to obtain a melt.

[0053] Wherein, the raw materials are all oxides, and the purity of the raw materials is greater than or equal to 99.5%.

[0054] Specifically, the raw materials are weighed according to a certain ratio, and then mixed in a mixer; the mixed raw materials are put into a melting furnace and heated to 1200°C-1800°C to melt the raw materials, The melt was obtained.

[0055] Preferably, the mixed raw materials are first heated to 1400°C-1600°C to melt the raw materials, and then heated to 1500°C-1700°C and kept for 2h-10h to clarify and homogenize the molten raw materials . Among them, the clarification is to remove the gas and impurities generated during the h...

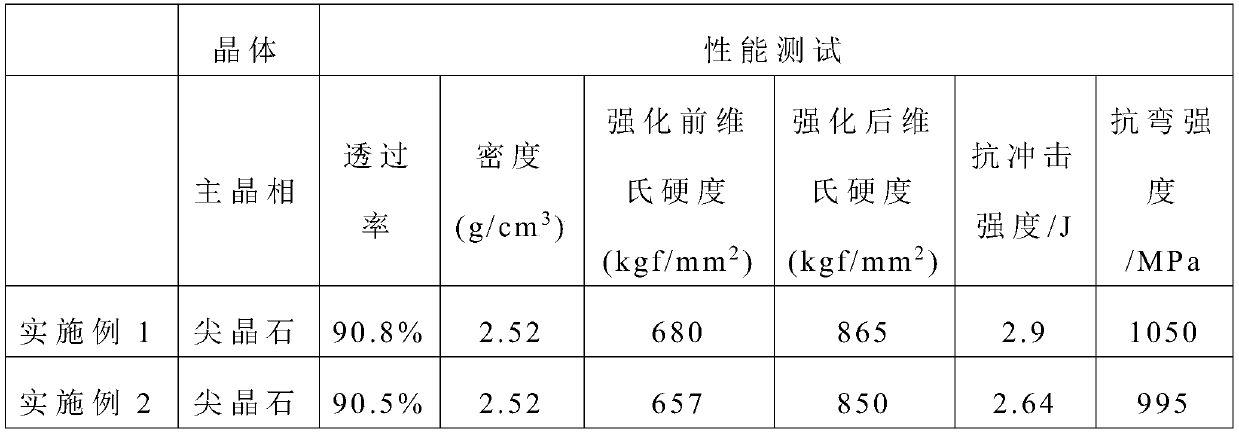

Embodiment 1

[0078] Weigh and mix raw materials according to the following components and mass ratio: 52% SiO 2 , 18% Al 2 o 3 , 12.5% Na 2 O, 2% K 2 O, 8% MgO, 1% CaO, 6% TiO 2 , 0.3% ZrO 2 , 0.1% P 2 o 5 and 0.1% Sb 2 o 3 . Pour the mixed raw materials into a melting furnace, gradually heat to 1600°C to melt the raw materials, and then continue to heat to 1650°C for 8 hours to clarify and homogenize the melt to obtain the melt. The molten material is placed in a mold for cooling and molding to obtain a semi-finished product.

[0079] The semi-finished product is then put into a crystallization furnace for heat treatment. Firstly, heat the crystallization furnace to 820°C at a certain heating rate and keep it for 4 hours; then heat the crystallization furnace at a certain heating rate to 950°C and keep it for 2 hours, take it out after cooling to a suitable temperature, and use the prepared The material is placed in a molten salt for ion exchange for strengthening treatment ...

Embodiment 2

[0081] Weigh and mix raw materials according to the following components and mass ratio: 52% SiO 2 , 18% Al 2 o 3 , 12% Na 2 O, 2.5% K 2 O, 7.5% MgO, 0.8% CaO, 0.5% Li 2 O, 0.3% ZnO, 0.1% Fe 2 o 3 , 5.5% TiO 2 , 0.5% ZrO 2 , 0.1% P 2 o 5 and 0.2% Sb 2 o 3 . Pour the mixed raw materials into the melting furnace, gradually heat to 1600°C to melt the raw materials, and then continue to heat to 1650°C for 8 hours to clarify and homogenize the melt to obtain the melt. The molten material is placed in a mold for cooling and molding to obtain a semi-finished product.

[0082] The semi-finished product is then put into a crystallization furnace for heat treatment. Firstly, the crystallization furnace was heated to 800°C at a certain heating rate, and kept for 4 hours; then, the crystallization furnace was heated to 880°C at a certain heating rate, kept for 2 hours, cooled to a suitable temperature, taken out, and the prepared The material is placed in a molten salt for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com