Fixing mechanism of punching machine for machining bicycle wheel spoke holes

A fixing mechanism and hole processing technology, applied in bicycle accessories, perforating tools, metal processing equipment, etc., can solve the problems of rim deformation, affecting the service life of the wheel, and unable to guarantee the precision of the processing. Practicality, the effect of convenient wheel rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

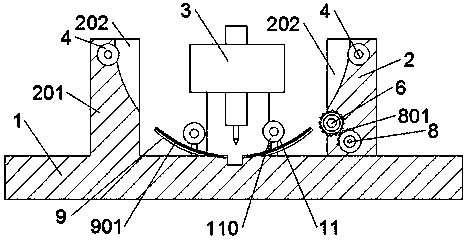

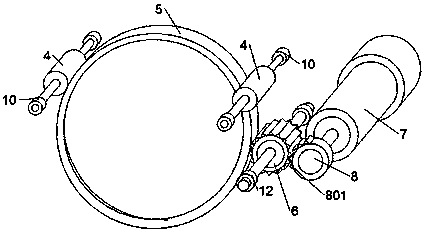

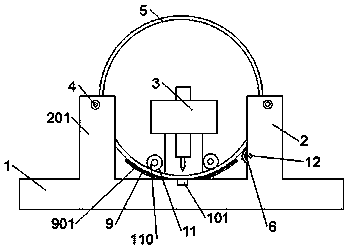

[0031] Such as Figure 1-Figure 6 As shown, the fixing mechanism of the bicycle wheel spoke hole processing punch provided by this embodiment includes a processing table 1 and a first support column 2 and two support columns 201 symmetrically distributed on the upper end surface side of the processing table 1. The first support column 2 and the second support column 201 are provided with a wheel groove 202, and the other side of the upper end surface of the processing table 1 is fixedly provided with a punching part 3, and the wheel is placed around the punching part 3, so that the punching part 3 can directly process the spoke holes of the wheel. The struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com