Moisture preservation and skin care face mask and preparation process thereof

A facial mask and facial mask liquid technology, applied in the direction of skin care preparations, cosmetic preparations, dressing preparations, etc., can solve the problems of inability to lock water, poor overall application effect, and decreased skin elasticity. Achieve the effect of avoiding rapid water loss, good overall application effect, and diluting small fine lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

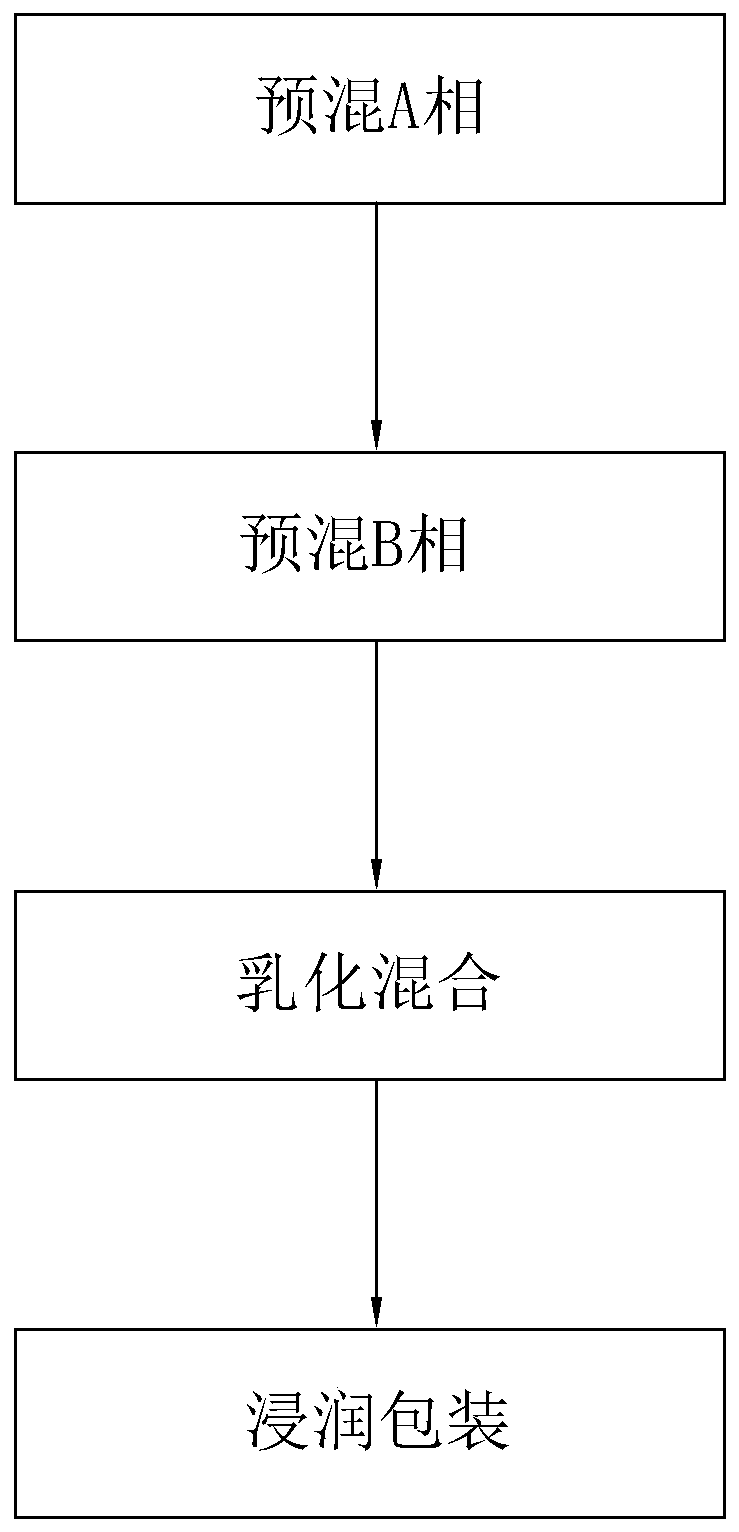

Method used

Image

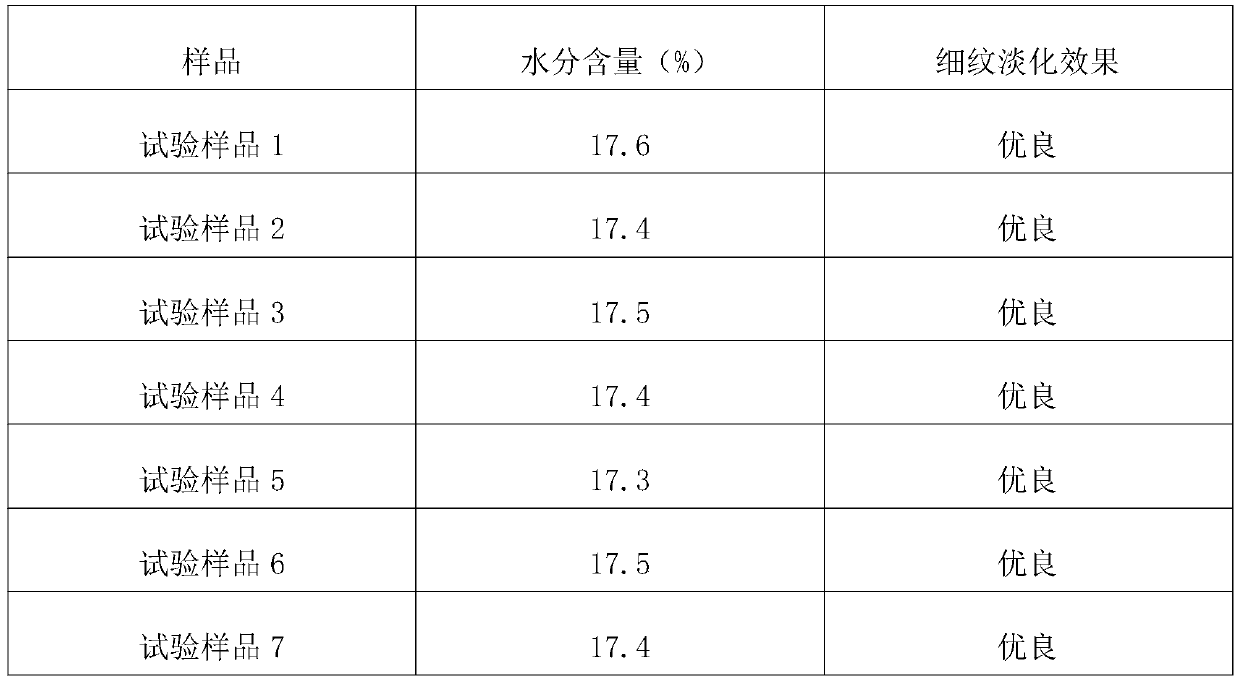

Examples

Embodiment 1

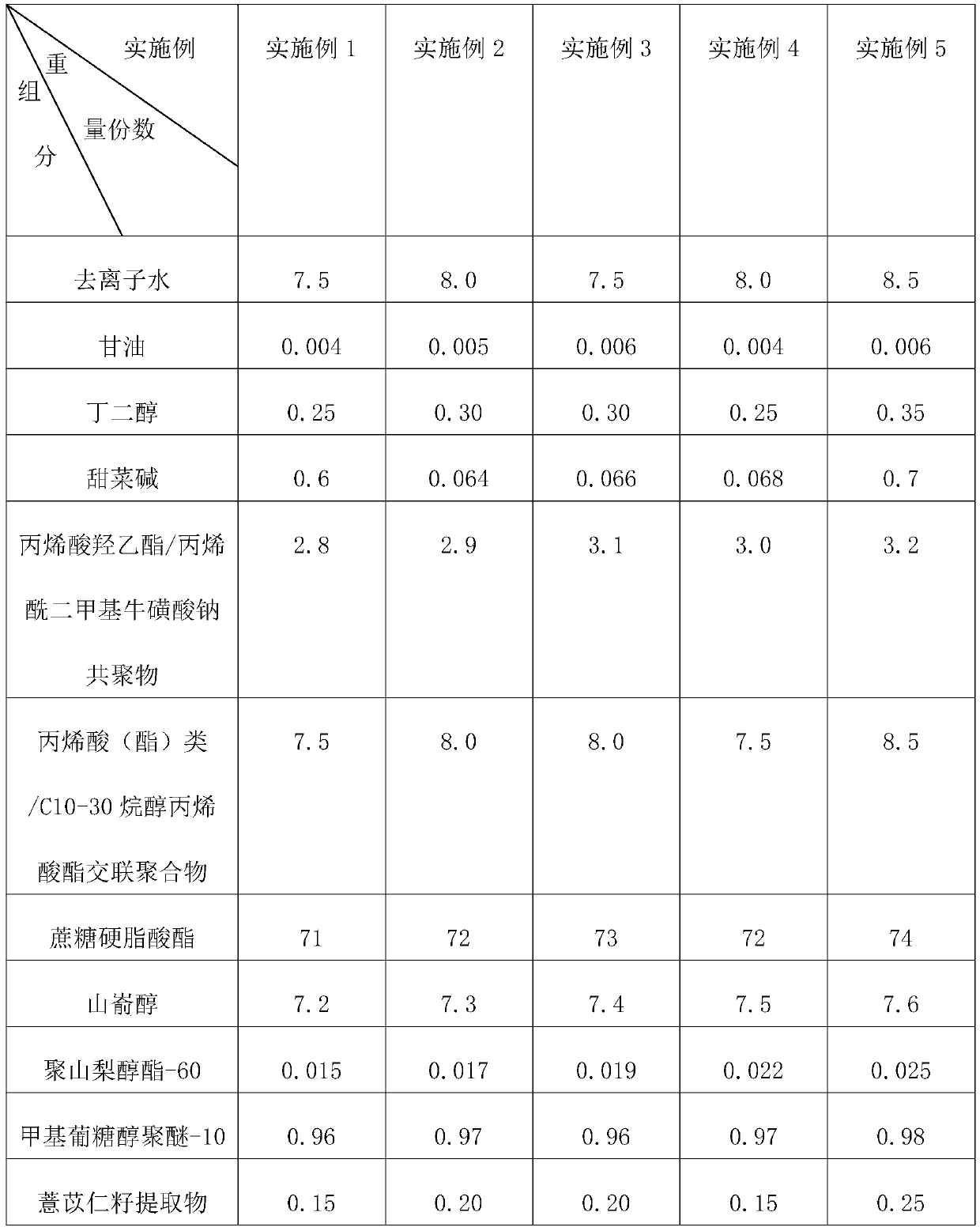

[0051] Embodiment 1: a kind of moisturizing skin care facial mask comprises facial mask cloth and facial mask liquid, each component of facial mask liquid and corresponding parts by weight thereof are as shown in table 1, and facial mask is prepared by following steps:

[0052] Step 1, premix phase A, add butanediol, deionized water, betaine, behenyl alcohol and coix seed extract to the emulsification pot according to the weight percentage, homogenize for 7.5min, rotate at 40rpm, and then heat to 74 ℃, stir and mix evenly, set aside;

[0053] Step 2, premixing phase B, the corresponding weight percentage of glycerin, hydroxyethyl acrylate / sodium acryloyl dimethyl taurate copolymer, acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, Add sucrose stearate, polysorbate-60 and methyl gluceth-10 into the stirring pot for stirring and mixing, the stirring speed is 50rpm, the stirring time is 17.5min, and it is ready for use;

[0054] Step 3, emulsification and mixing,...

Embodiment 2

[0057] Embodiment 2: a kind of moisturizing skin care mask, with the difference of embodiment 1, is prepared by the following steps:

[0058] Step 1, premix phase A, add butanediol, deionized water, betaine, behenyl alcohol and coix seed extract to the emulsification pot according to the weight percentage, homogenize for 5 minutes, rotate at 50rpm, and then heat to 70°C , Stir to mix evenly, set aside;

[0059] Step 2, premixing phase B, the corresponding weight percentage of glycerin, hydroxyethyl acrylate / sodium acryloyl dimethyl taurate copolymer, acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, Add sucrose stearate, polysorbate-60 and methyl gluceth-10 into the stirring pot for stirring and mixing, the stirring speed is 40rpm, the stirring time is 25min, stand-by;

[0060] Step 3, emulsification and mixing, reduce the temperature in the emulsification pot containing phase A to 30°C by deionized water cooling, then add phase B, keep warm and vacuumize to d...

Embodiment 3

[0062] Embodiment 3: a kind of moisturizing skin care mask, with the difference of embodiment 1, is prepared by the following steps:

[0063] Step 1: Premix phase A, add butanediol, deionized water, betaine, behenyl alcohol and coix seed extract to the emulsification pot according to the weight percentage, homogenize for 10 minutes, rotate at 30rpm, and then heat to 78°C , Stir to mix evenly, set aside;

[0064] Step 2, premixing phase B, the corresponding weight percentage of glycerin, hydroxyethyl acrylate / sodium acryloyl dimethyl taurate copolymer, acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, Add sucrose stearate, polysorbate-60 and methyl gluceth-10 into the stirring pot for stirring and mixing, the stirring speed is 60rpm, the stirring time is 10min, stand-by;

[0065] Step 3, emulsification and mixing, reduce the temperature in the emulsification pot with phase A to 40°C by deionized water cooling, then add phase B, keep warm and vacuumize to defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com