Point location calculation method for complex spatial hole system programming

A calculation method and space technology, applied in the field of numerical control programming, can solve the problems of high point calculation error rate, long point determination time, no systematic calculation method, etc., and achieve high point accuracy and high point calculation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

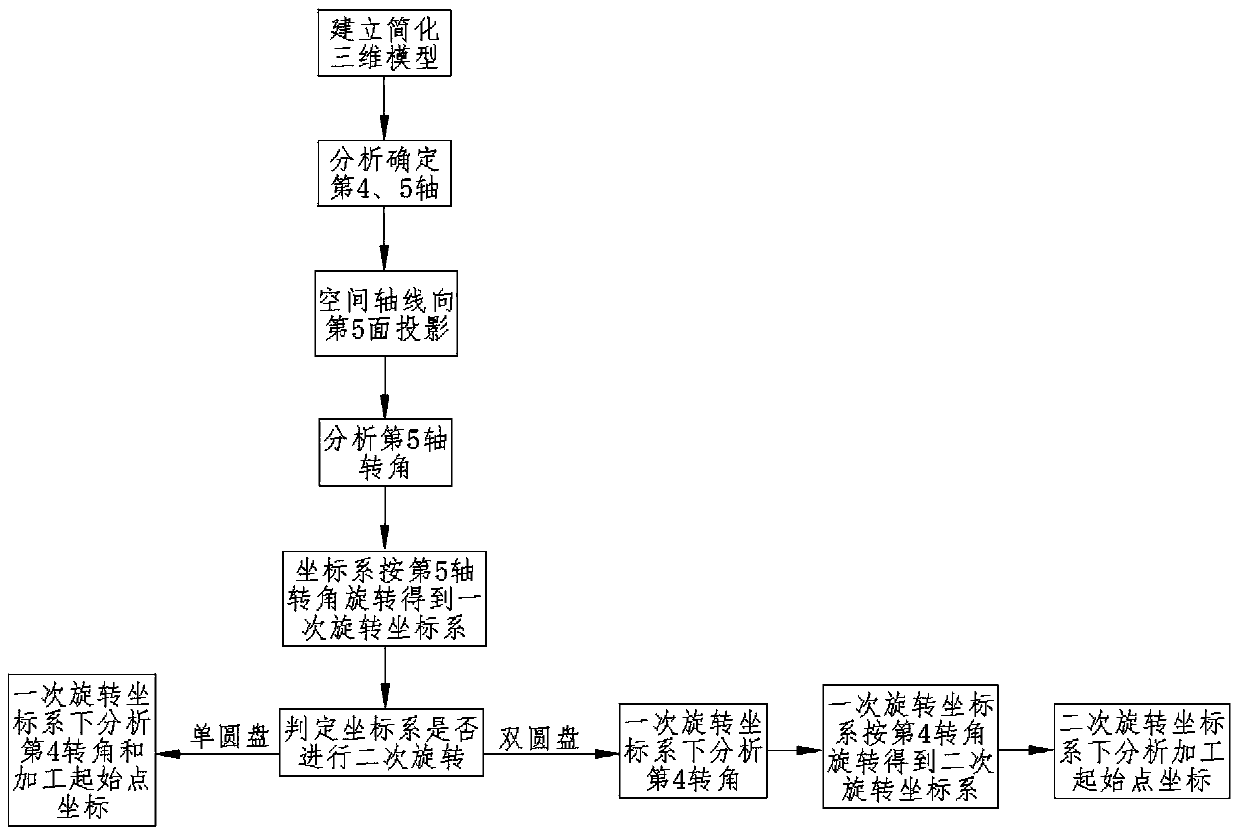

[0020] The following examples illustrate the point calculation method of complex spatial hole system programming in further detail. The specific steps are as follows:

[0021] Step 1. Use software and right-hand rule to establish a simplified three-dimensional model, the software has the function of coordinate system translation and rotation;

[0022] Step 2: According to the type of machine tool, including single disc and double disc, analyze and determine the 4th and 5th axis;

[0023] Step 3: Project the space axis to the 5th plane, analyze the angle between the projection line and the common axis; the plane parallel to the 5th axis is the 5th axis projection plane, referred to as the 5th plane; the plane parallel to the 4th axis is the first 4-axis projection plane, referred to as plane 4; the intersection line of plane 4 and plane 5 is the common axis;

[0024] Step 4. Determine whether the angle is positive or negative according to the right-hand screw rule to obtain the 5th axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com