A hydrostatic bearing, a hydrostatic turntable and a hydrostatic spindle

A hydrostatic and bearing technology, applied in the field of hydrostatic rotary table, hydrostatic spindle, and hydrostatic bearing, can solve the problems of rotation accuracy, influence accuracy, bearing failure, etc. Error equalization effect, uniform pressure distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

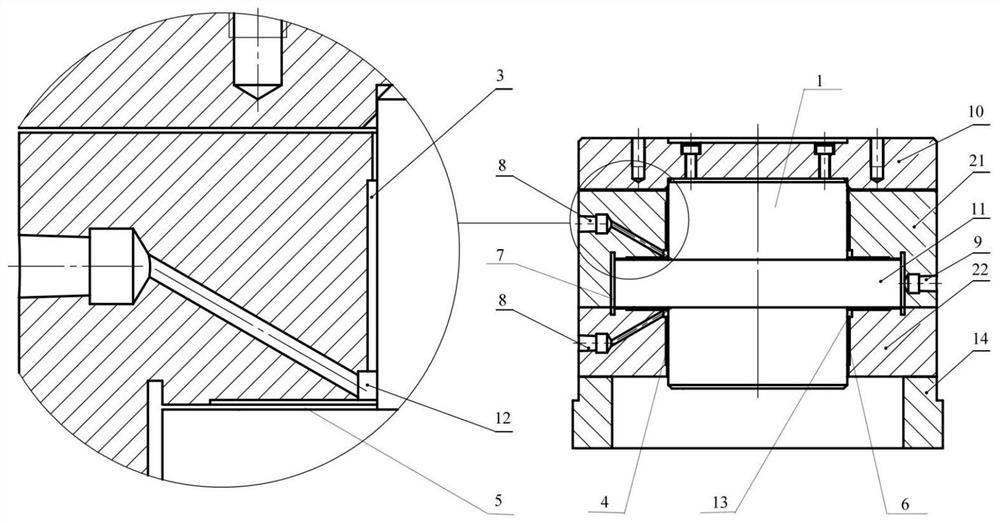

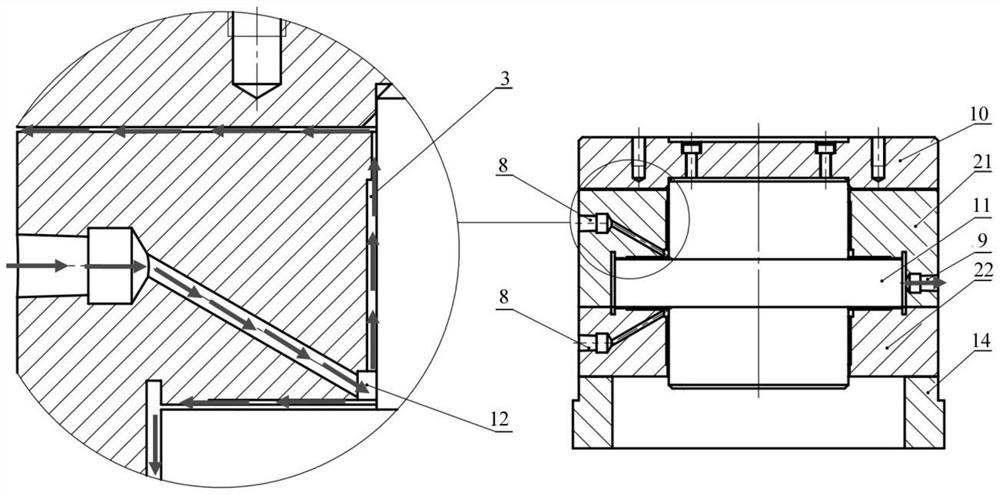

[0022] A hydrostatic bearing, comprising a main shaft 1 and a shaft sleeve 2, the main shaft 1 is a cylindrical structure with an annular flange 11 in the middle, the longitudinal section of the main shaft 1 is in the shape of a "middle", the The shaft sleeve 2 is a cylindrical structure with an annular groove in the middle, and the shaft sleeve 2 is set on the main shaft 1, and keeps the main shaft 1 and the shaft sleeve 2 with The coaxiality, the annular flange 11 is located inside the annular groove, a gap of 2-30 μm is maintained between the shaft sleeve 2 and the main shaft 1, the cylindrical structure above the annular flange 11 and the shaft sleeve There is an annular hole I3 between the two, and an annular hole II4 is arranged between the cylindrical structure below the annular flange 11 and the sleeve 2. The annular hole I3 and the annular hole II4 have the same structure and are symmetrical to each other. , the longitudinal sections of the annular aperture I3 and th...

specific Embodiment approach 2

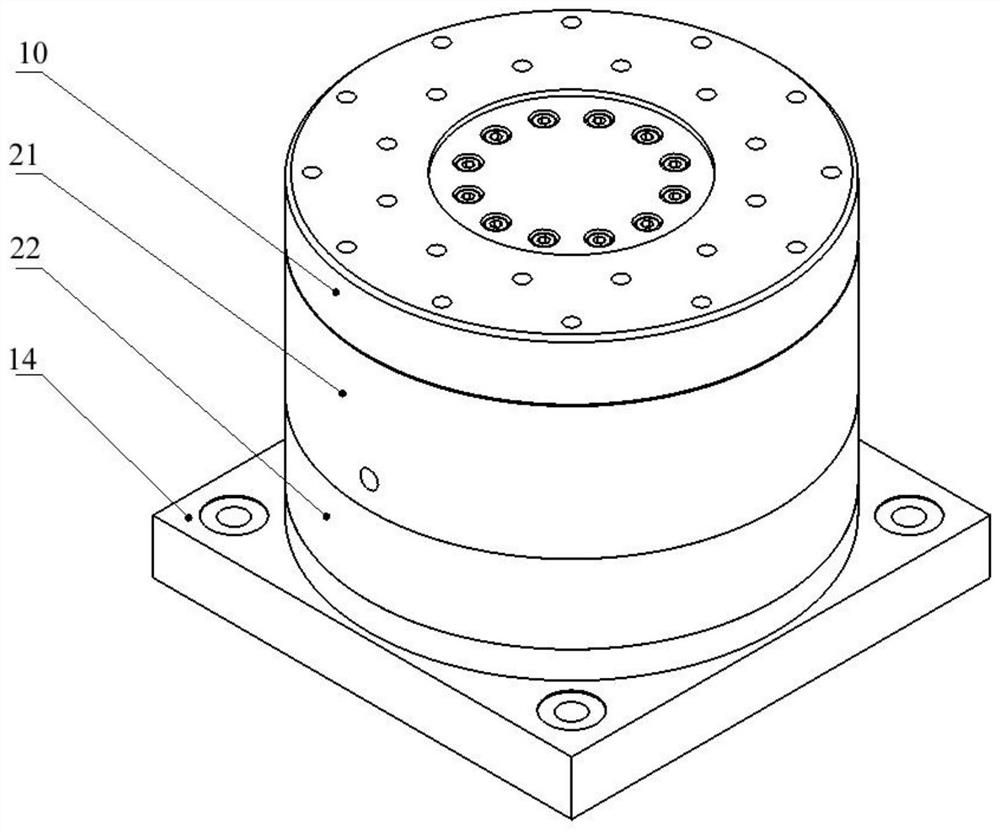

[0037] A hydrostatic turntable, including the hydrostatic bearing described in Embodiment 1 and the turntable base 14, the turntable base 14 is located under the shaft sleeve 2 and is fixedly connected and positioned with the shaft sleeve 2, as image 3 shown.

specific Embodiment approach 3

[0038] A surface throttling hydrostatic spindle: including the hydrostatic bearing described in Embodiment 1 and the spindle base 15, the spindle base 15 is located below the bushing 2 and is fixedly connected to the bushing 2, as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com