Sleeve end plate for achieving grouting connection and PHC pipe pile

A PHC pipe pile, grouting connection technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, to achieve the effect of improving flexural rigidity, conducive to the flexural resistance of the pile head, and the effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other implementations obtained by persons of ordinary skill in the art without making creative efforts fall within the protection scope of the present invention.

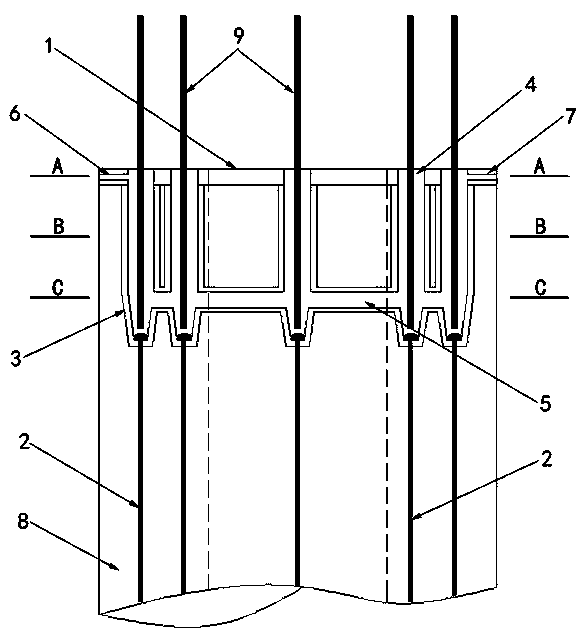

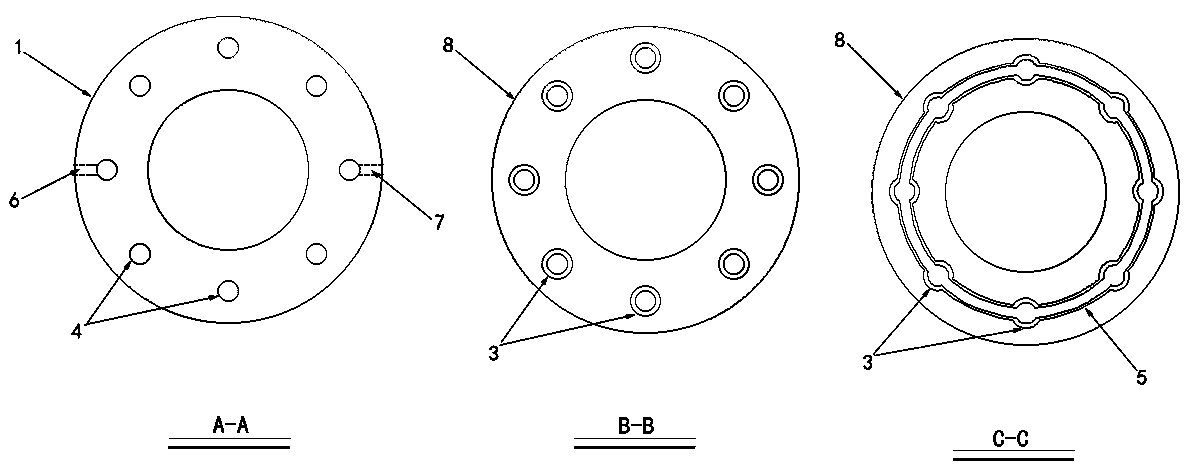

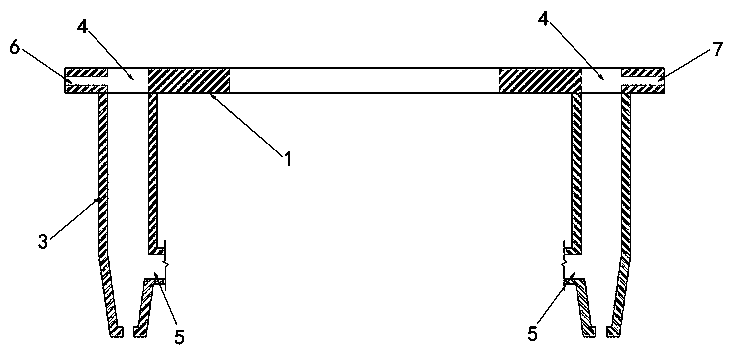

[0025] Such as Figures 1 to 4 As shown, this embodiment provides a sleeve end plate for realizing grouting connection, including an annular end plate 1, and the lower end surface of the end plate 1 corresponds to the prestressed steel rod 2 one by one. There are several steel sleeves 3, and the end plate 1 opposite to the steel sleeves 3 is provided with a connecting hole 4 communicating with the inner cavity of the steel sleeves 3, and a connecting pipe 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com