Environment-friendly rubber and plastic product and preparation method thereof

A green and environmentally friendly technology for rubber and plastic products, applied in the rubber field, can solve the problems of excessive VOC emissions, large compression permanent deformation, and non-environmental protection, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

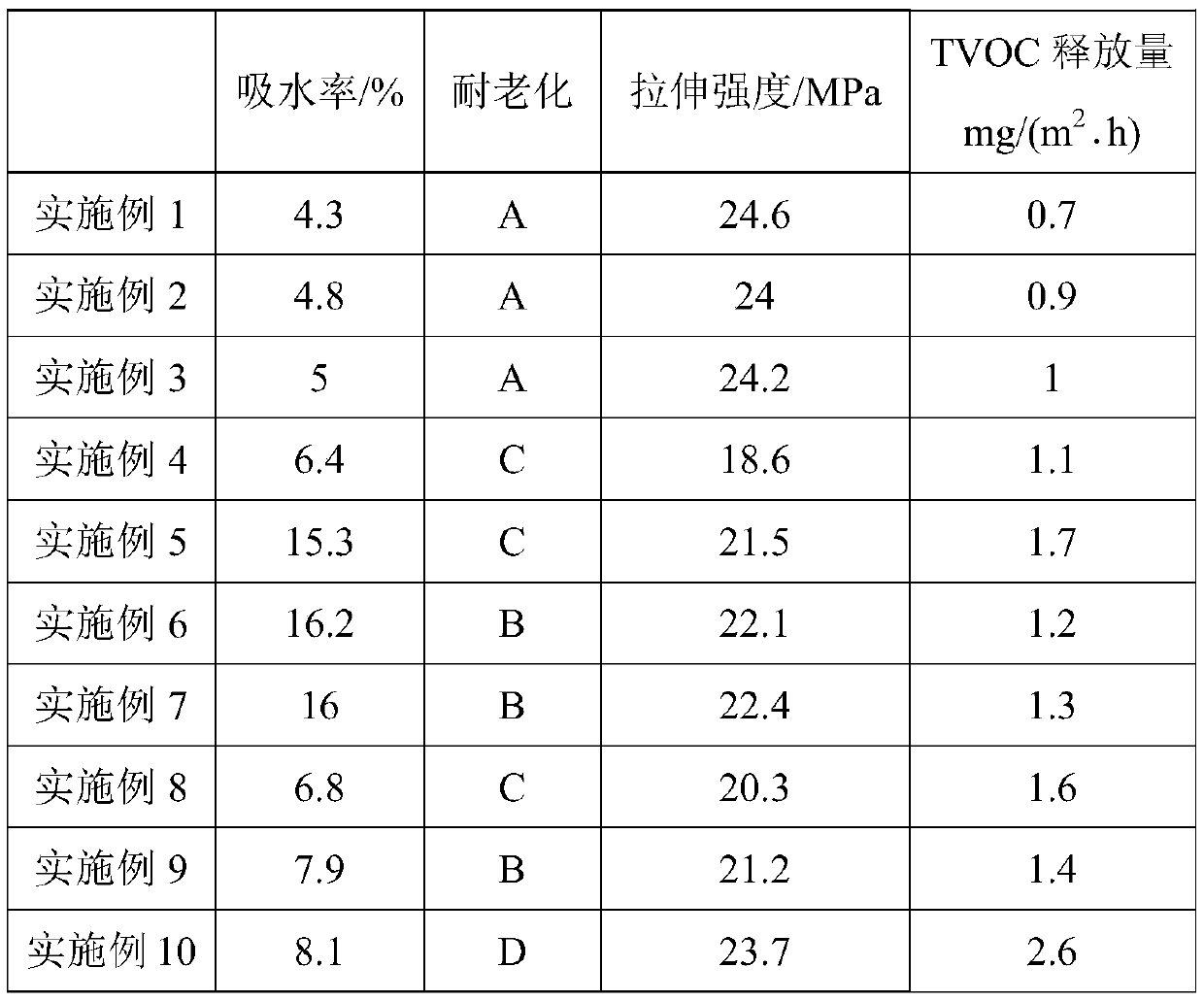

Examples

preparation example Construction

[0088] The second aspect of the present invention provides a method for preparing green environmental protection rubber and plastic products, the preparation method at least includes the following steps:

[0089] (1) Add nitrile rubber, polyvinyl chloride resin, protective wax, filler, flame retardant, foaming agent, active agent, chlorinated paraffin, and deodorant to the internal mixer and blend until the temperature of the blend reaches 140 -180℃ discharging;

[0090] (2) Put the intensive training materials into the training machine and cool down to resume training. When the temperature drops to 60-100 ° C, open the slices and store them for 20-26 hours after cooling;

[0091] (3) After the film is stored for 20-26 hours, continue to knead in the mill, add vulcanizing agent and accelerator, knead evenly, and then produce strips to obtain strips; extrude the strips through an extruder, and send them into an oven for drying For vulcanization and foaming, the oven temperatur...

Embodiment 1

[0097] Provided is a green and environment-friendly rubber and plastic product. In parts by weight, the preparation raw materials include: 14 parts of nitrile rubber, 5 parts of polyvinyl chloride resin, 4 parts of protective wax, 4.6 parts of filler, 4.7 parts of flame retardant, foaming agent 5 parts, 0.4 parts of active agent, 3 parts of accelerator, 0.2 parts of vulcanizing agent, 15 parts of chlorinated paraffin, 1.5 parts of deodorant.

[0098] The nitrile rubber can be obtained commercially, and the trade mark is JSRN230S.

[0099] The trade mark of described polyvinyl chloride is SG7.

[0100] The microcrystalline wax can be obtained commercially from manufacturers including but not limited to Shanghai Junpu Chemical Co., Ltd.

[0101] The filler is modified light calcium carbonate.

[0102] The modified light calcium carbonate is silane modified light calcium carbonate.

[0103] The silane is a combination of N-(6-aminohexyl)aminomethyltriethoxysilane and octadecyl...

Embodiment 2

[0117] Provided is a green and environment-friendly rubber and plastic product. The preparation raw materials include at least 10 parts by weight of nitrile rubber, 3 parts of polyvinyl chloride resin, 2 parts of protective wax, 1 part of filler, 4 parts of flame retardant, foaming 4 parts of agent, 0.2 part of active agent, 1 part of accelerator, 0.1 part of vulcanizing agent, 10 parts of chlorinated paraffin, and 0.3 part of deodorant.

[0118] The nitrile rubber can be obtained commercially, and the trade mark is JSRN230S.

[0119] The trade mark of described polyvinyl chloride is SG7.

[0120] The microcrystalline wax can be obtained commercially from manufacturers including but not limited to Shanghai Junpu Chemical Co., Ltd.

[0121] The filler is modified light calcium carbonate.

[0122] The modified light calcium carbonate is silane modified light calcium carbonate.

[0123] The silane is a combination of N-(6-aminohexyl)aminomethyltriethoxysilane and octadecyldime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com