Method for producing titanium dioxide by extracting titanium dioxide from titanium-containing blast furnace slag

A technology of titanium dioxide and blast furnace slag, which is applied in the preparation of titanium dioxide, titanium compounds, titanium oxide/hydroxide, etc., can solve problems such as low economic and social benefits, substandard physical and mechanical properties, and unstable titanium alloy composition. Achieve the sound development of economic and social benefits, optimize the titanium extraction process, and improve the effect of titanium extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

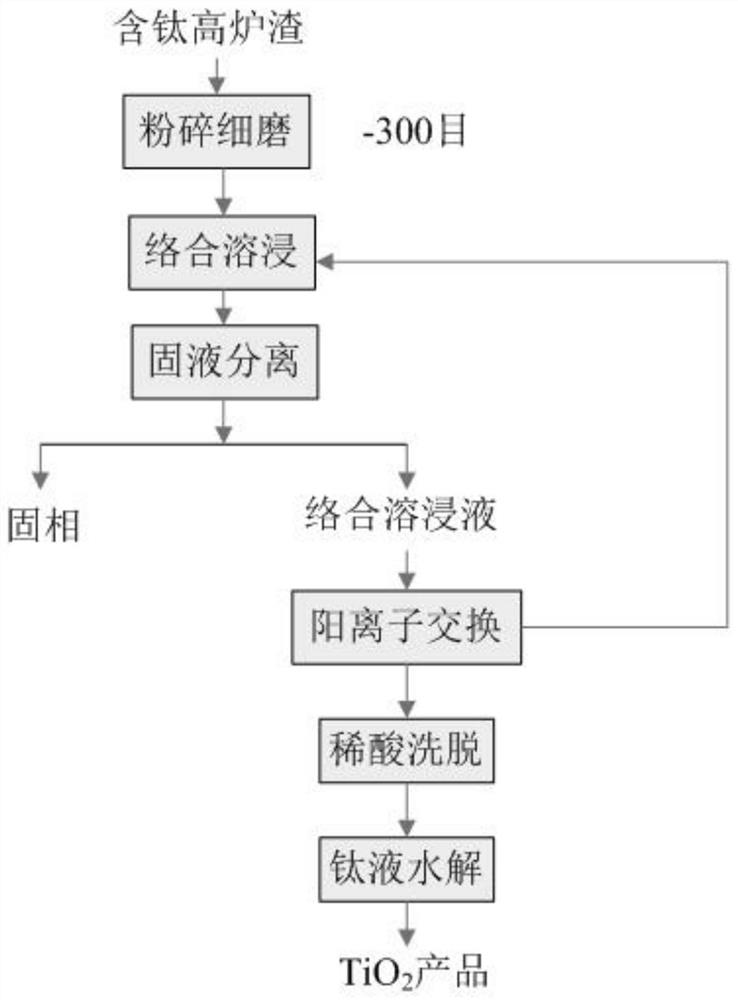

[0024] Such as figure 1 Shown, the present invention comprises the following steps:

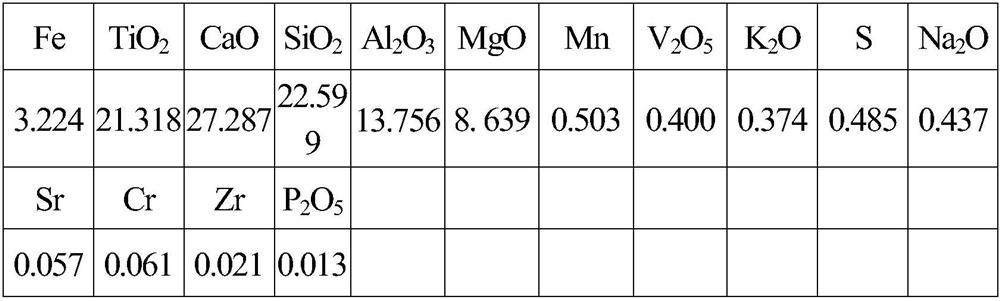

[0025] (1) A. Dry the blast furnace slag and grind it into powder; take 1000Kg of blast furnace slag and dry it at 100-110°C for 2-4 hours to constant weight, crush and finely grind it to below -300 mesh (<0.048mm), Mix well and use it as a sample for later use. The XRF test results are shown in Table 1, and the TiO2 content is 21.318%.

[0026]

[0027] B. Add ascorbic acid and sulfuric acid to the blast furnace slag powder and stir evenly, then let stand and soak for 1 day; the ratio of ascorbic acid and sulfuric acid is 1:1, and the concentration of ascorbic acid is 2-5%.

[0028] C. Separation of solid and liquid, and ascorbic acid is used to wash the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com