System and method for removing hydrogen sulfide and co-producing calcium carbonate and sulfur from gypsum

A calcium carbonate, hydrogen sulfide technology, applied in chemical instruments and methods, calcium carbonate/strontium/barium, sulfur compounds, etc., can solve problems such as low concentration, shortage of sulfur resources, national security threats, etc., to improve SO2 concentration, technology The effect of mature technology and high system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

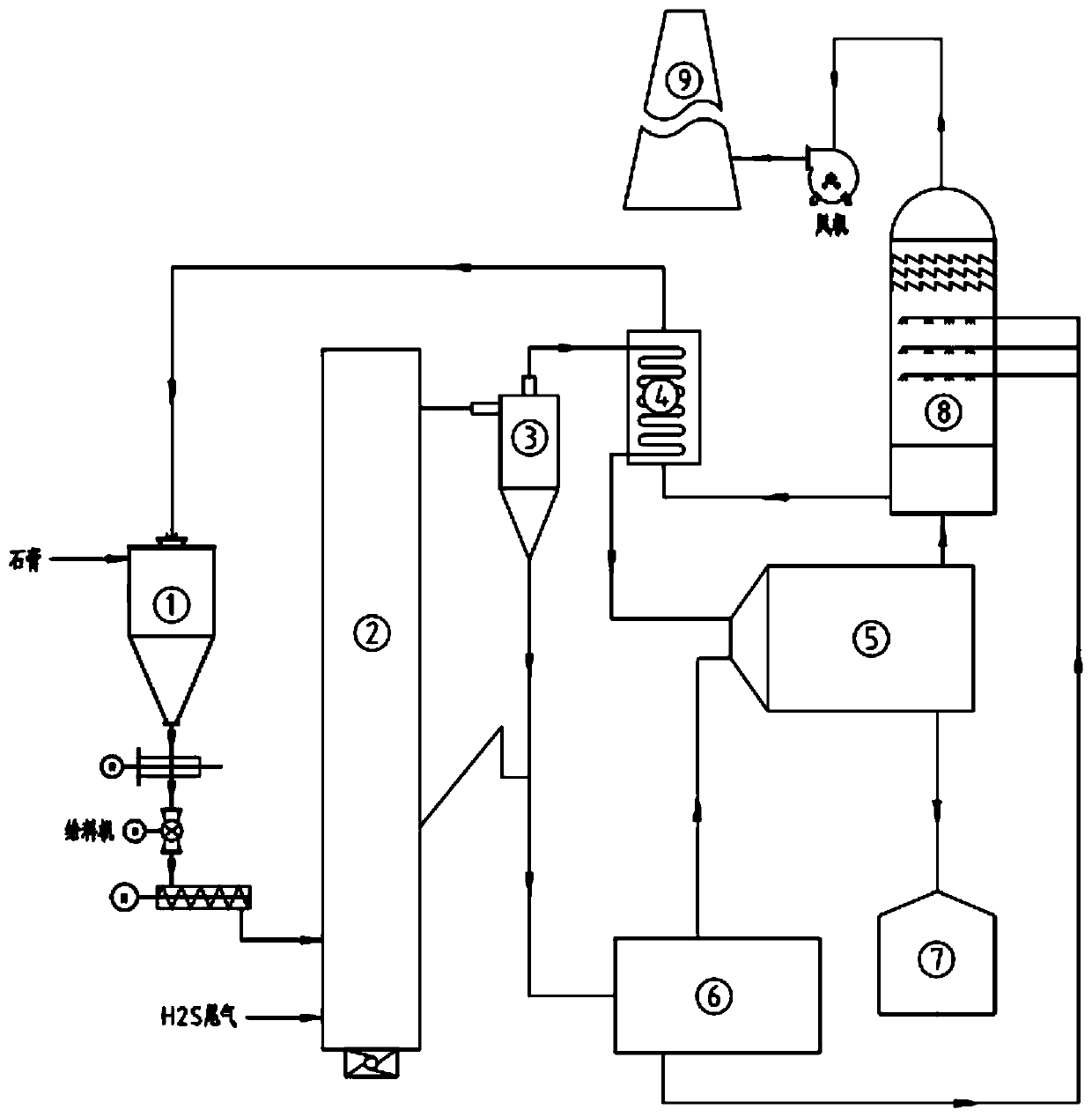

[0052] Such as figure 1 As shown, the removal of H from gypsum 2 S co-production of CaCO 3 and sulfur systems, including:

[0053] Reduction calciner 2, high temperature separator 3, gypsum drying-preheater 4, Claus reactor 5, H 2 O-CO 2 Processor 6, sulfuric acid storage tank 7, desulfurization tower 8, chimney 9 and gypsum storage bin 1.

[0054] The high-temperature separator 3 is connected with the product outlet of the reducing calciner 2, and the solid outlet of the high-temperature separator 3 is connected with the H 2 O-CO 2 Inlet connection of processor 6, H 2 O-CO 2 The gas outlet of the processor 6 is connected to the Claus reactor 5, the heat medium inlet of the gypsum drying-preheater 4 is connected to the gas outlet of the high-temperature separator 3, and the heat medium outlet of the gypsum drying-preheater 4 is connected to the Claus reactor 5. Adams reactor 5 communicates.

[0055] The tail gas outlet of the Claus reactor 5 communicates with the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com