Pneumatic tire, tire vulcanization mold, and method for producing pneumatic tire using tire vulcanization mold

A tire vulcanization mold, a technology for pneumatic tires, applied in the direction of tire tread/tread pattern, tire parts, tires, etc., to achieve the effect of suppressing the reduction of wet braking performance, excellent noise performance, and improving noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

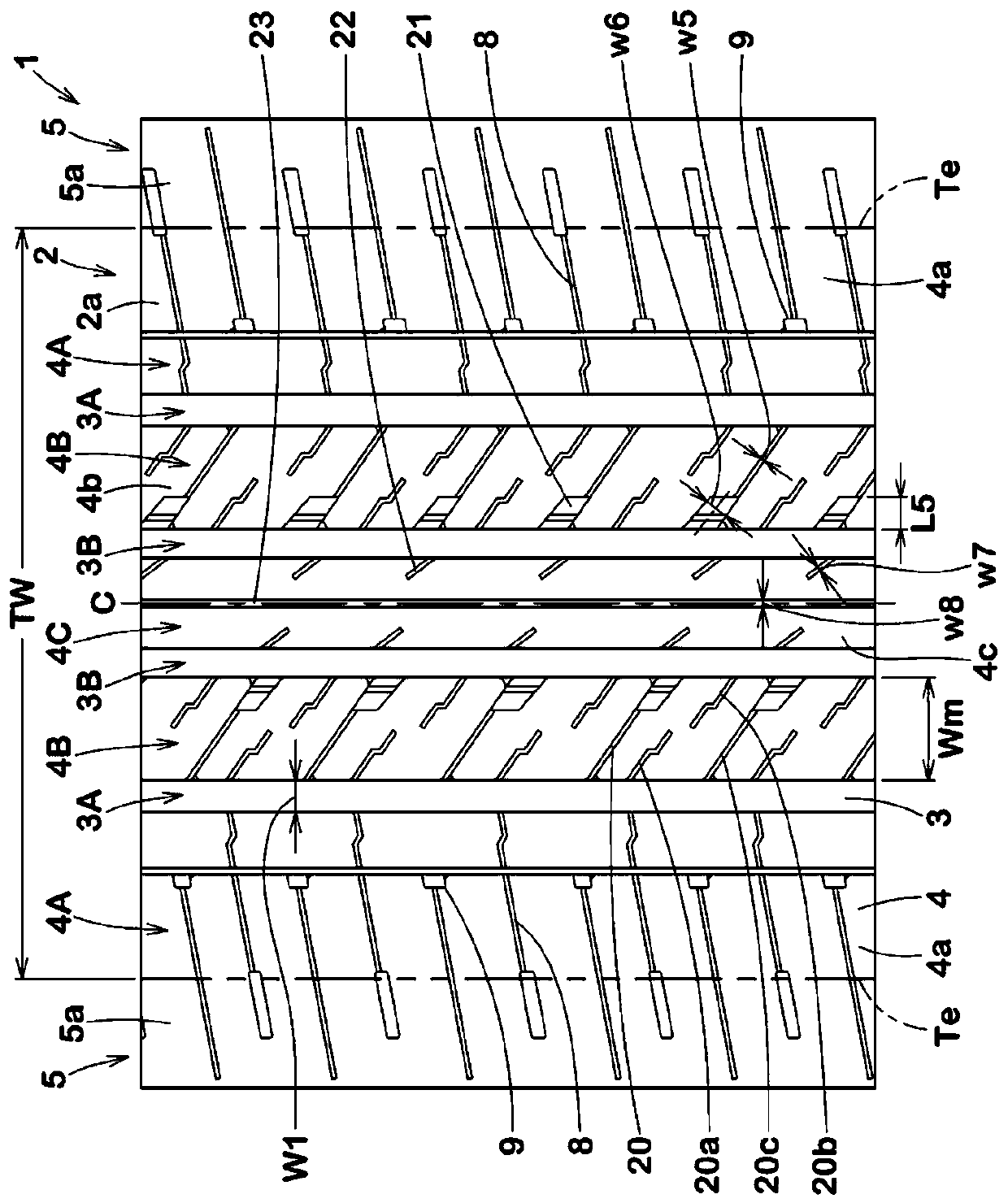

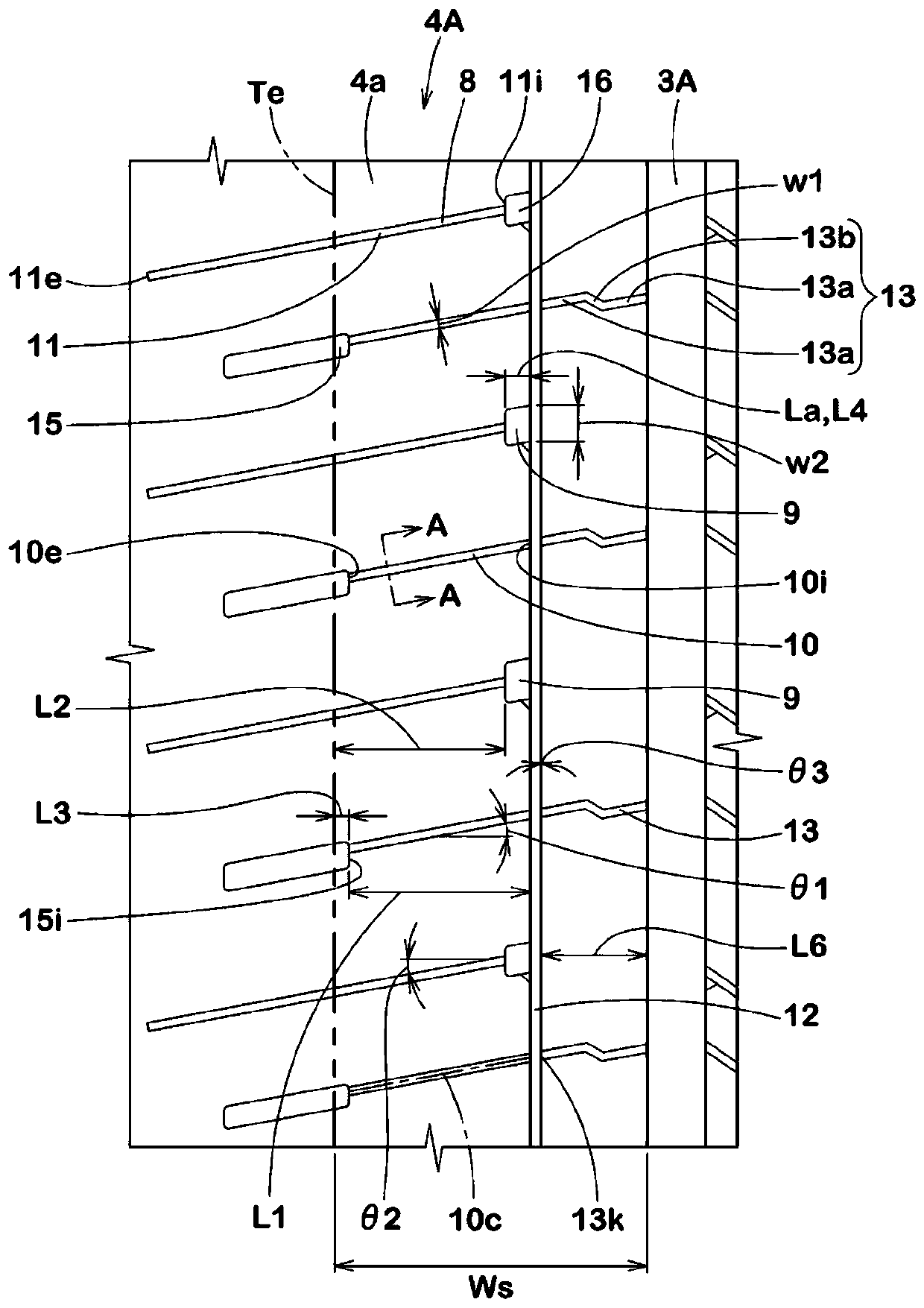

[0088] use Figure 5 The tire curing mold shown is manufactured with figure 1 Pneumatic tires with the basic pattern, and tested the wet road braking performance and noise performance of each pneumatic tire. Common specifications and test methods for each tire are as follows.

[0089] Tread width TW: 165mm

[0090] Width of the first groove (w2 / Ws): 9(%)

[0091] Width of the second groove (w2 / Ws): 15(%)

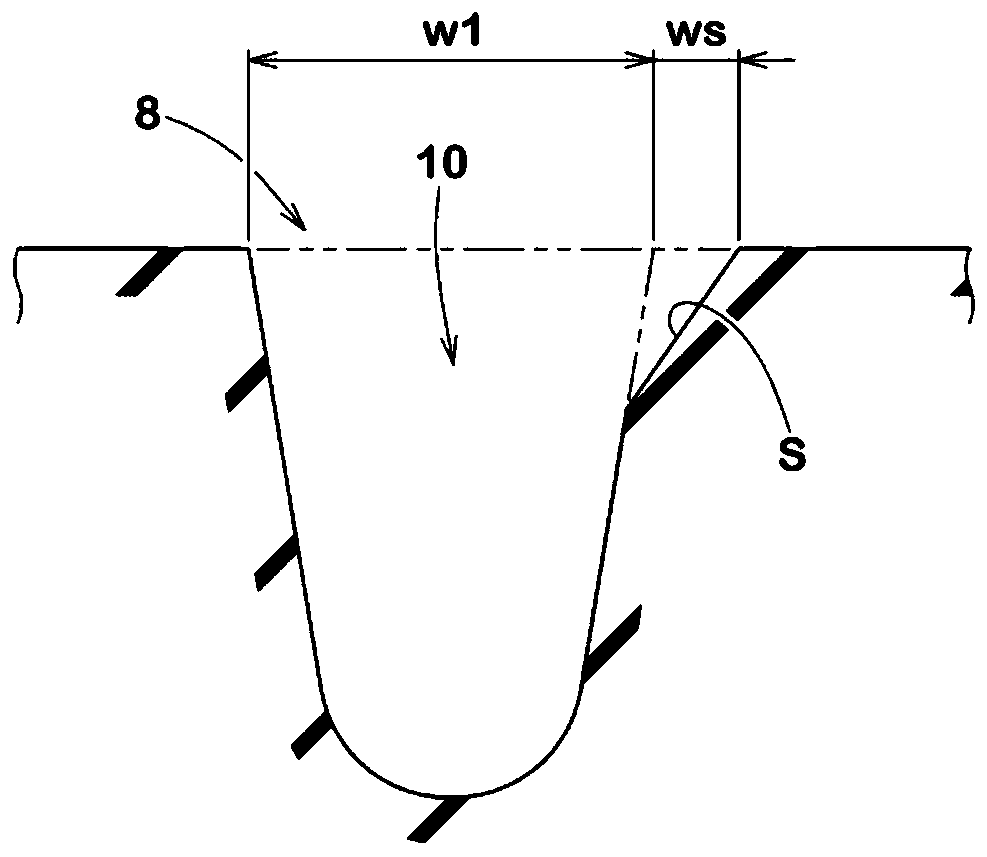

[0092] The width (w3 / Ws) of the dimple: 9(%)

[0093] Width w1 of the first sipe, the second sipe, and the fourth sipe: 0.8mm

[0094] Width w1 of the third sipe: 1.2mm

[0095] Tire size: 215 / 65R16

[0096] Rims: 16×6J

[0097] Internal pressure (front wheel / rear wheel): 240 / 290kPa

[0098]

[0099] The following vehicles equipped with test tires on all wheels were driven on a test course on a wet asphalt road with a water depth of 5 mm, and the braking performance when driving straight and turning at this time was evaluated according to the sense of the test dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com