Wet desulfurization system and wet desulfurization method

A wet desulfurization and desulfurization tower technology, applied in the desulfurization field, can solve the problems of easily breaking the water balance of the desulfurization system, the burden of large desulfurization wastewater treatment, waste of thermal energy and water resources, etc., and achieves the removal of fine pollutants and white smoke. Phenomenon, effect of desulfurization wastewater emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

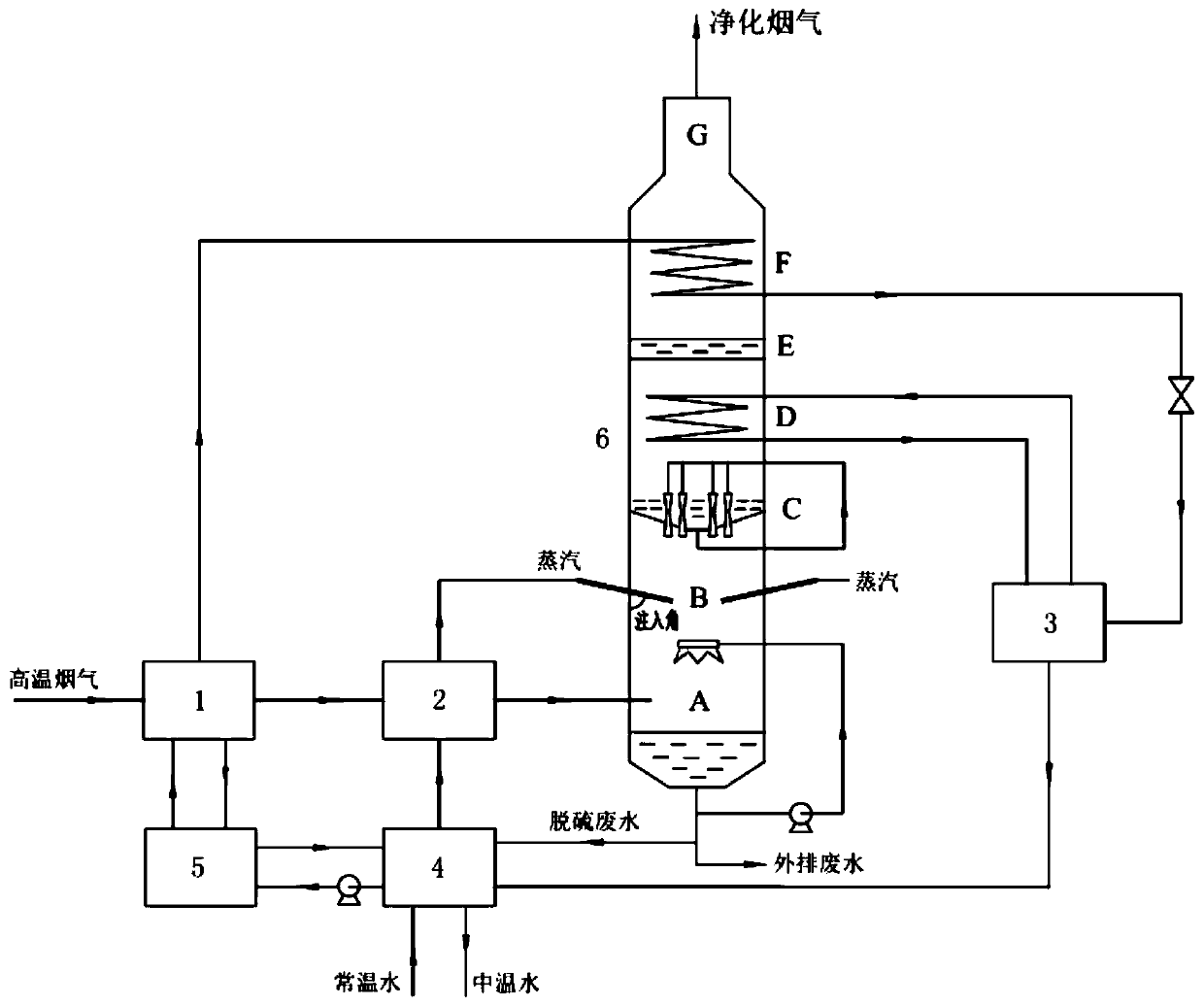

[0041] See attached figure 1, this embodiment provides a wet desulfurization system, which includes a desulfurization tower 6 and a split heat pump system. The interior of the desulfurization tower 6 includes a cooling absorption section A, a steam injection section B, and a spray washing section C from bottom to top. , deep cooling section D, demisting section E, flue gas heating section F and flue gas outlet section G. The split heat pump system includes a generator 1, a waste water evaporator 2, a cryogenic evaporator 3, an absorber 4, a heat exchanger 5, and a sulfur-containing flue gas inlet pipe connected to the cooling absorption section A of the desulfurization tower 6.

[0042] It should be noted that, in other embodiments, the spray washing section C or the demisting section E may be omitted as required.

[0043] A generator 1 and a waste water evaporator 2 are arranged in sequence along the flow direction of the sulfur-containing flue gas inlet pipe. The generator ...

Embodiment 2

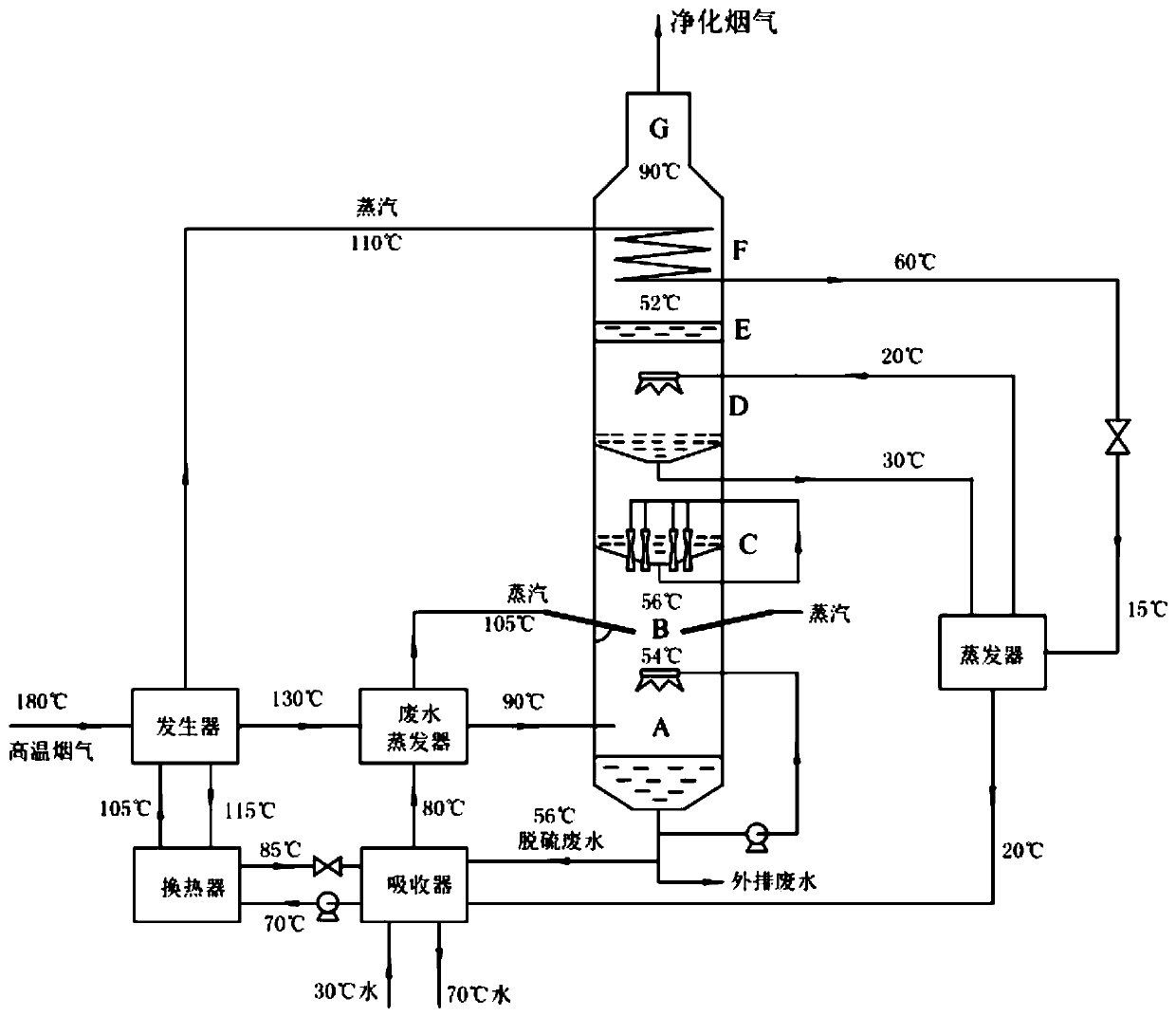

[0062] This embodiment also provides a specific wet desulfurization method using the wet desulfurization system of Embodiment 1.

[0063] See attached figure 2 , the steam injection section B of the desulfurization tower of the wet desulfurization system has two steam injection ports, and the injection angle between the steam injection direction and the wall of the desulfurization tower is 30°. The deep cooling water and flue gas in the deep cooling section can adopt the direct contact spray heat exchange type; the refrigerant liquid is lithium bromide solution; the demister of the demisting section E of the desulfurization tower is a baffle demister. in, figure 2 The evaporator in is a deep cooling evaporator.

[0064] The 180°C high-temperature flue gas from the waste heat boiler enters the generator, and enters the waste water evaporator after the temperature drops to 130°C. After evaporating the waste water, the flue gas temperature drops to 90°C and enters the desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com