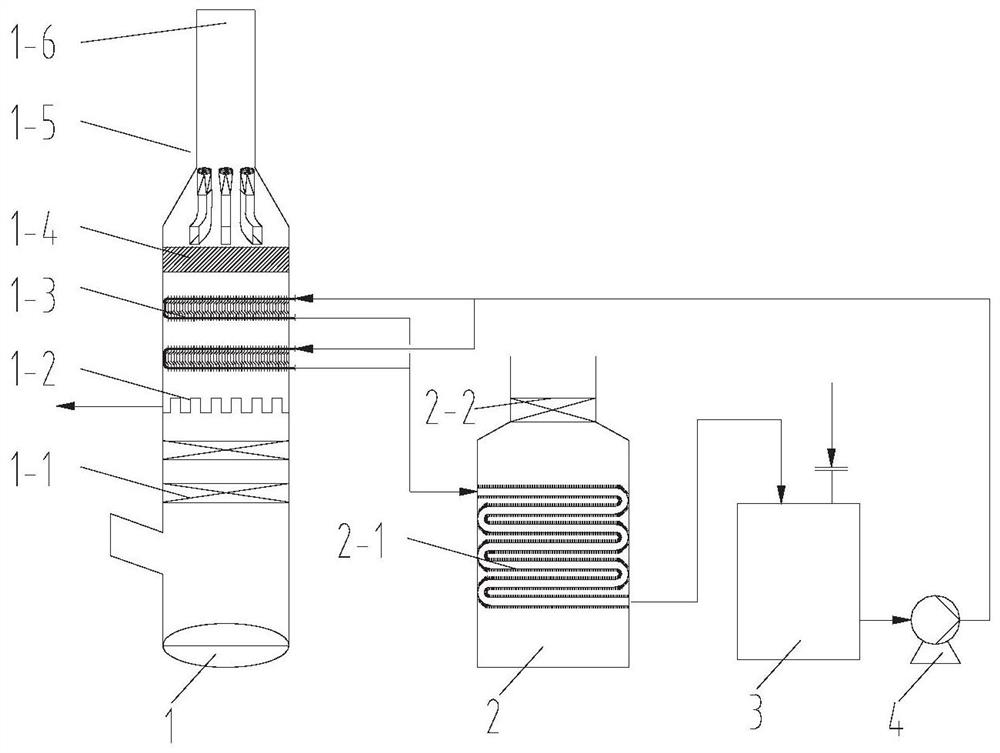

A device and method for water collection and whitening of wet flue gas with low energy consumption

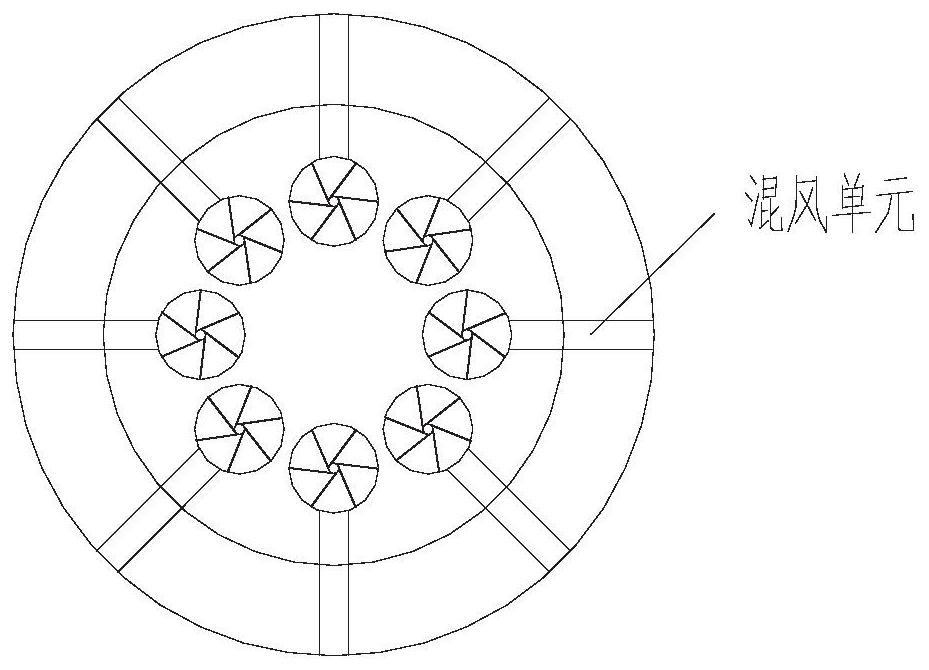

A technology with wet flue gas and low energy consumption, applied in the field of resources and environment, can solve the problems of high energy consumption of the mixing fan and large area occupied by the mixing device, achieve the elimination of unsaturated emissions, reduce the cost of water for enterprises, reduce the mixing The effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

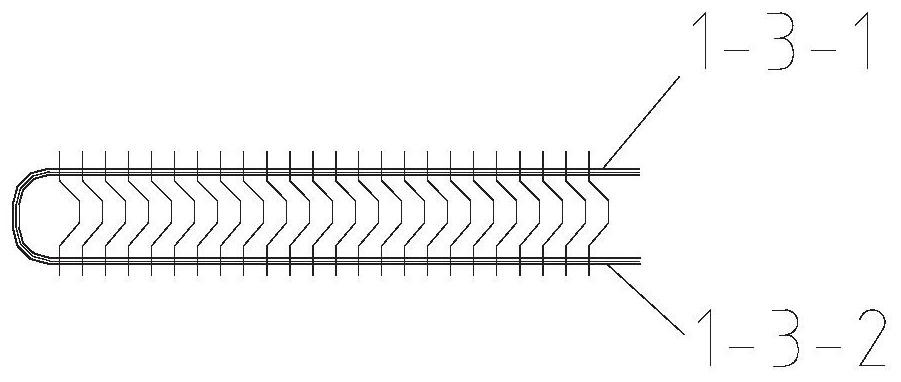

[0056] The high-humidity flue gas collected in the washing workshop of a printing and dyeing factory is dewhitened by the technical solution of the present invention, and the flue gas volume is 100,000 Nm 3 / h, the temperature of the smoke entering the tower is 50-60°C, the condenser in the condensation and cooling layer is equipped with two layers, the cooling liquid circulation system uses lithium bromide as the condensate, and the condensate circulation is 150m 3 / h, the recovered water volume is 5t / h. The outlet area of the air mixing unit accounts for 35% of the cross-sectional area of the flue, and the air mixing volume is 30000Nm 3 / h, the ambient temperature is 10°C, the humidity of the flue gas at the chimney outlet is lower than 75%, and there is no white smoke at the chimney outlet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com