Efficient flue gas type lithium bromide absorption type cold and hot water unit for eliminating white smoke

A hot water unit, flue gas type technology, applied in adsorption machines, refrigerators, climate change adaptation and other directions, can solve the problems of chimney condensate precipitation, corrosion, investment cost increase, etc. The effect of reducing heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

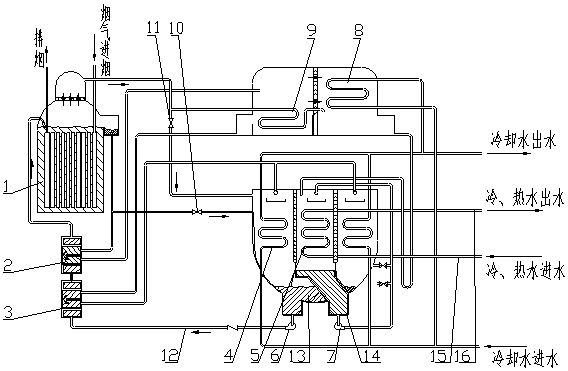

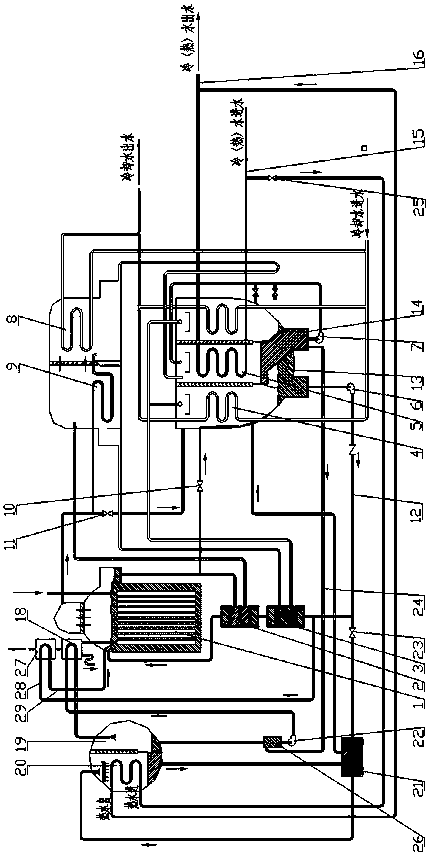

[0048] White smoke elimination high-efficiency flue gas type lithium bromide absorption type cold and hot water unit of the present invention is in such as figure 2 On the basis of heating at room temperature and flue gas exhaust type lithium bromide absorption type cold and hot water units, a flue gas solution heat exchanger 27, a flue gas solution heat exchanger dilute solution pipeline 28, and a flue gas solution heat exchanger dilute solution pipeline 28 are added. The solution pipeline 29 and the additional flue gas solution heat exchanger 27 are arranged on the exhaust pipe of the flue gas heat exchanger 18. The flue gas from the flue gas high-pressure generator 1 enters the flue gas heat exchanger 18 first, and then enters the Discharge after the flue gas solution heat exchanger 27; and the newly added diluted solution pipeline 28 of the inlet flue gas solution heat exchanger and the diluted solution pipeline 29 of the outlet flue gas solution heat exchanger have three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com