Knitted fully-formed 3D mask

A fully formed, mask technology, applied in knitting, weft knitting, decorative textiles, etc., can solve problems such as pain, non-fitting, stuffy feeling, etc., achieve good environmental protection, improve manufacturing efficiency, and improve airtightness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

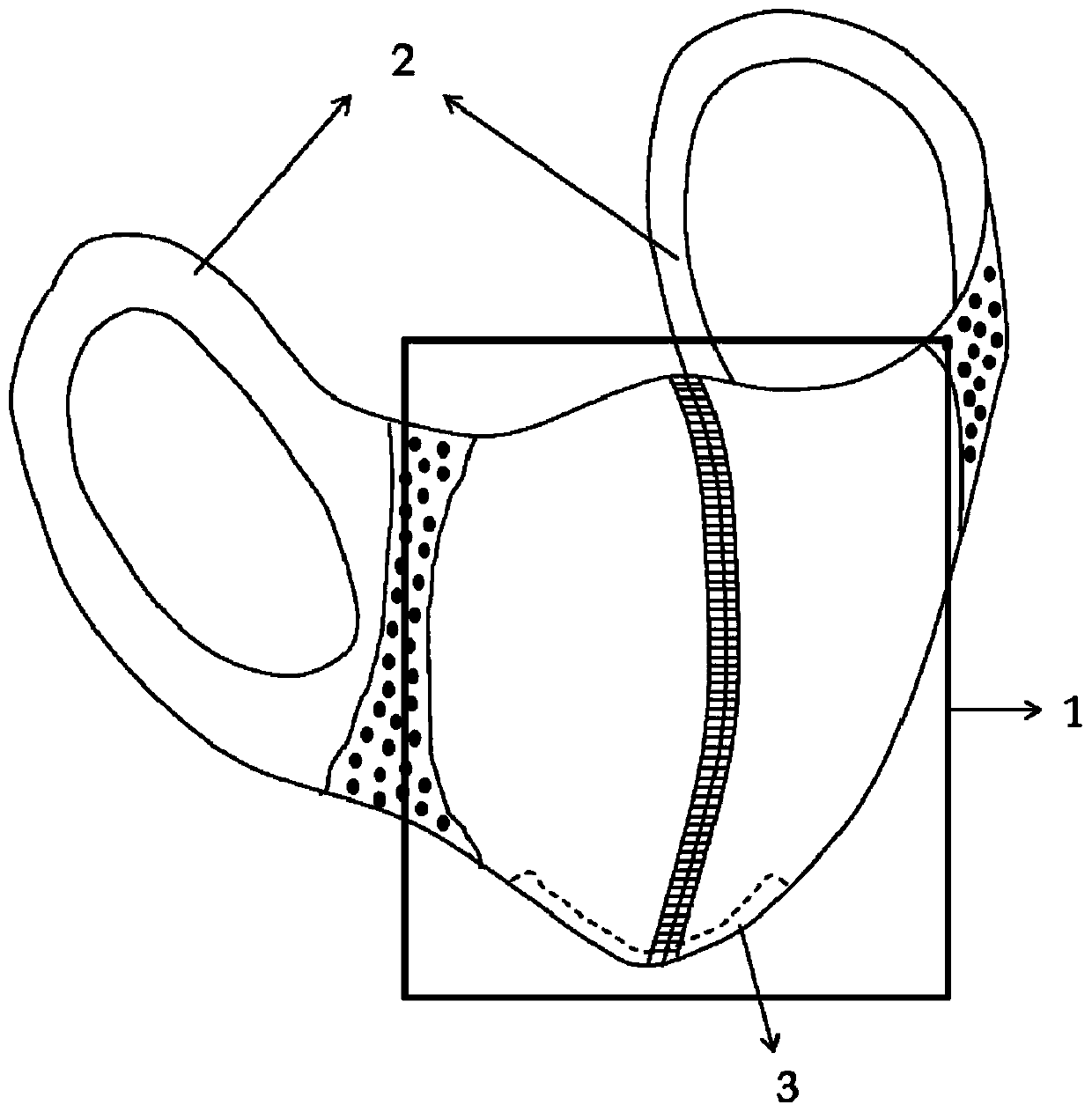

[0037] Embodiment 1: A kind of knitting fully formed 3D mask

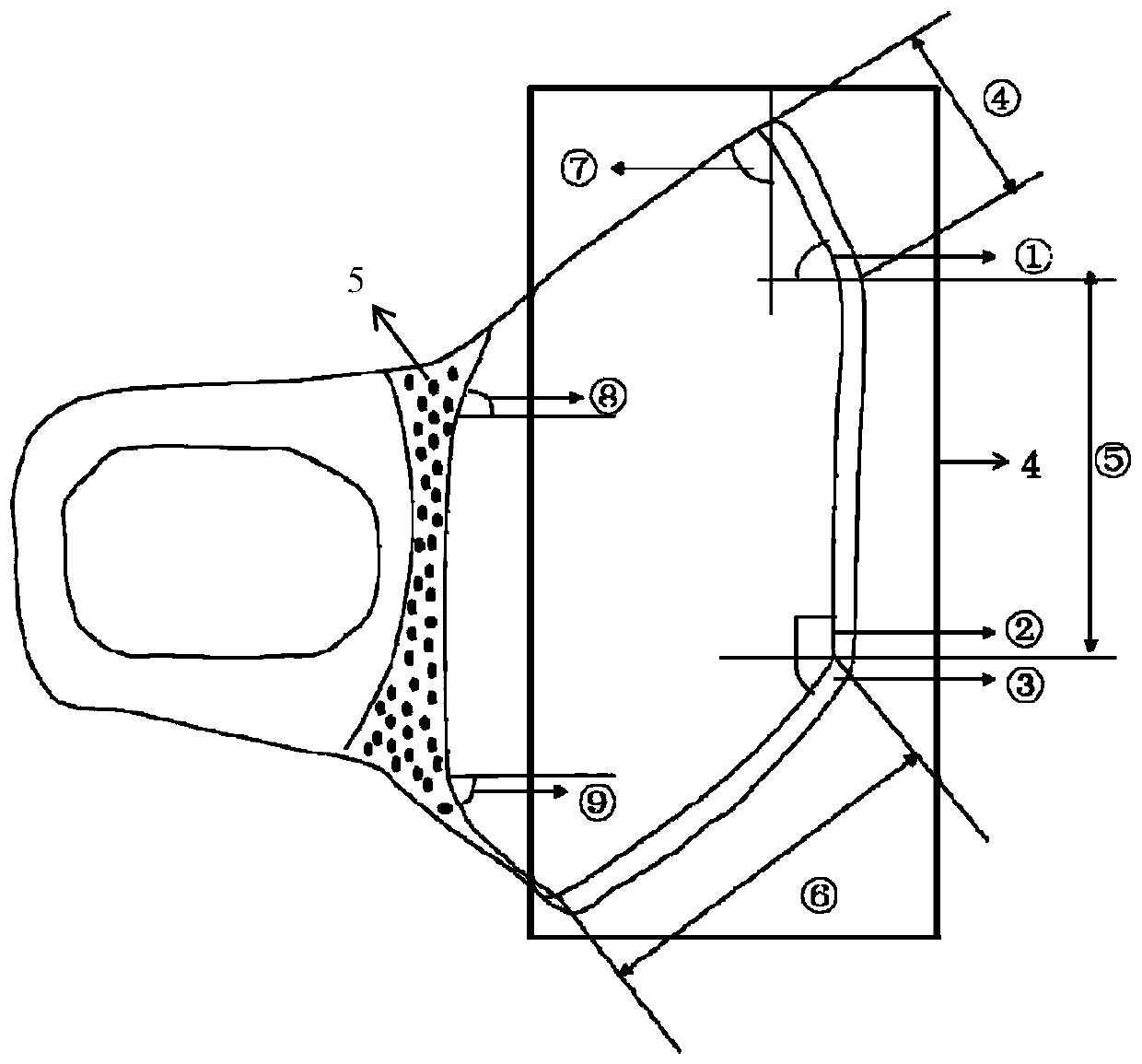

[0038] Such as figure 1 and figure 2 As shown, it is a schematic diagram of the three-dimensional structure of the knitted fully formed 3D mask and the side angle design after folding, 1 is the cover body of the knitted fully formed 3D mask, 2 is the ear strap of the mask, and 3 is the opening of the mask cover , located directly below the mask body, with an opening length of 7cm; 4 is the curve distribution of the mask body after the mask is folded, considering the fit with the bridge of the nose, mouth and chin of the face, the angle between the bridge of the nose ① and the horizontal direction The angle between the nose and the vertical direction ⑦ is 55 degrees, the angle between the nose tip and the mouth connecting part ② and the horizontal direction is 90 degrees, and the length ⑤ is 7.5 cm; the mouth and chin The angle between the joint ③ and the horizontal direction is 55 degrees, and the length ⑥ is 5....

Embodiment 2

[0042] Embodiment 2: A kind of method for preparing knitted fully formed 3D mask

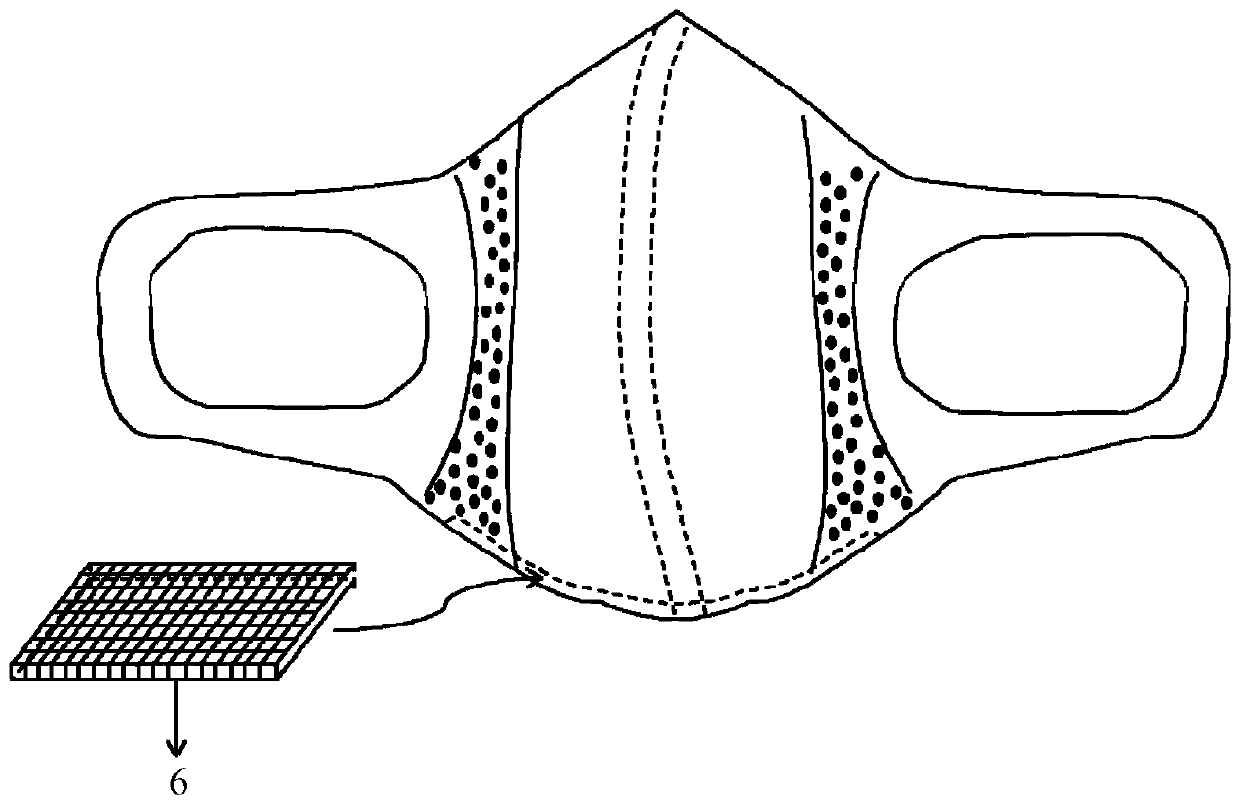

[0043] Such as Figure 5 As shown, it is a schematic diagram of knitting on the machine of the knitted fully formed 3D mask, 1 is the right ear strap, 2 is the right ear strap, 3 is the right ear strap, 4 is the tuck connection on the right ear side, 5 is The lower half of the back piece of the mask body, 6 is the lower half of the front piece, 7 is the upper half of the front piece, 8 is the upper half of the back piece, 9 is the tuck joint on the left ear side, and 10 is the left The ear band, 11 is the left ear band, and l2 is the left ear ear band. When knitting, start by knitting the earbands behind the ears first, then weave the air layer, knit once on the front bed and once on the back bed, do eight sets of cycles, and then form the earbands behind the ears through flat narrowing stitches; then through left narrowing stitches Weave the back strap of the right ear strap by adding stitche...

Embodiment 3

[0048] Embodiment 3: A kind of N95 mouth mask

[0049] Add multi-layer melt-blown non-woven fabric filter element to the knitted fully formed 3D mask prepared in Example 2, the fabric material can be selected from polypropylene, polyolefin, polyester and polyamide, etc., through the respiratory protective mask of GB2626-2019 and other indicators According to the test, the filtration efficiency can reach 98%, which meets the N95 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com