Urea-based additive, its use and preparation method

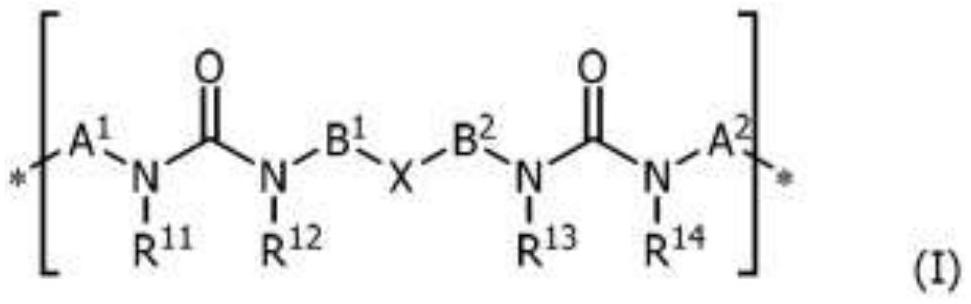

An additive, urea-based technology, used in: urea-based additives, which can solve problems such as being unsuitable for current and future requirements of advanced printed circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

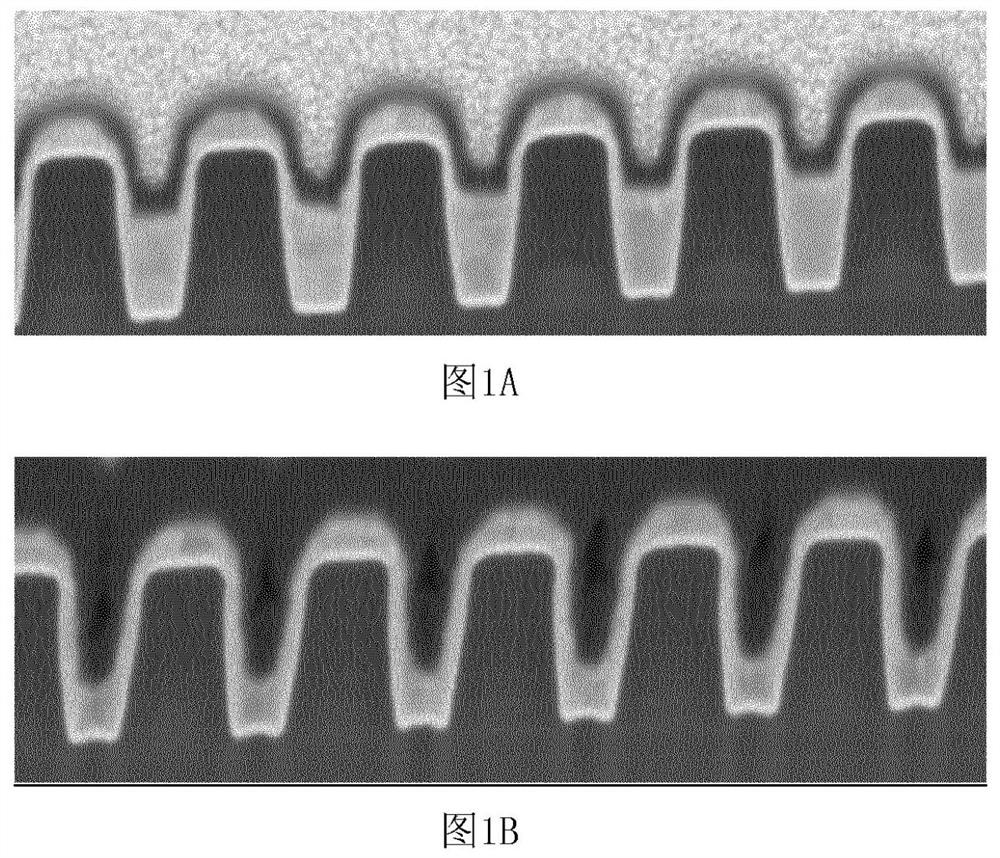

Image

Examples

example

[0385] Unless otherwise stated below, commercially available products were used as described in the technical data sheets available on the filing date of this specification. accelerator and Leveling agents are products available from Atotech Deutschland GmbH. Unless otherwise stated below, commercially available products were used as described in the technical data sheets available on the filing date of this specification.

[0386] Recorded at 400MHz with spectral shift 4300Hz, sweep width 9542Hz at 25°C 1 H-NMR spectroscopy (NMR spectrometer supplied by Bruker Corp.). Solvents used are d unless otherwise specified 6 -DMSO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com