A kind of lithium metal battery separator modified slurry and its application

A technology for lithium metal batteries and modified slurry, which is applied in the direction of lithium batteries, secondary batteries, battery components, etc., can solve the problems of difficult commercialization of lithium metal batteries, volume expansion, and uncontrollable growth of lithium dendrites. Achieve better lithium affinity and mechanical properties, improve cycle life, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

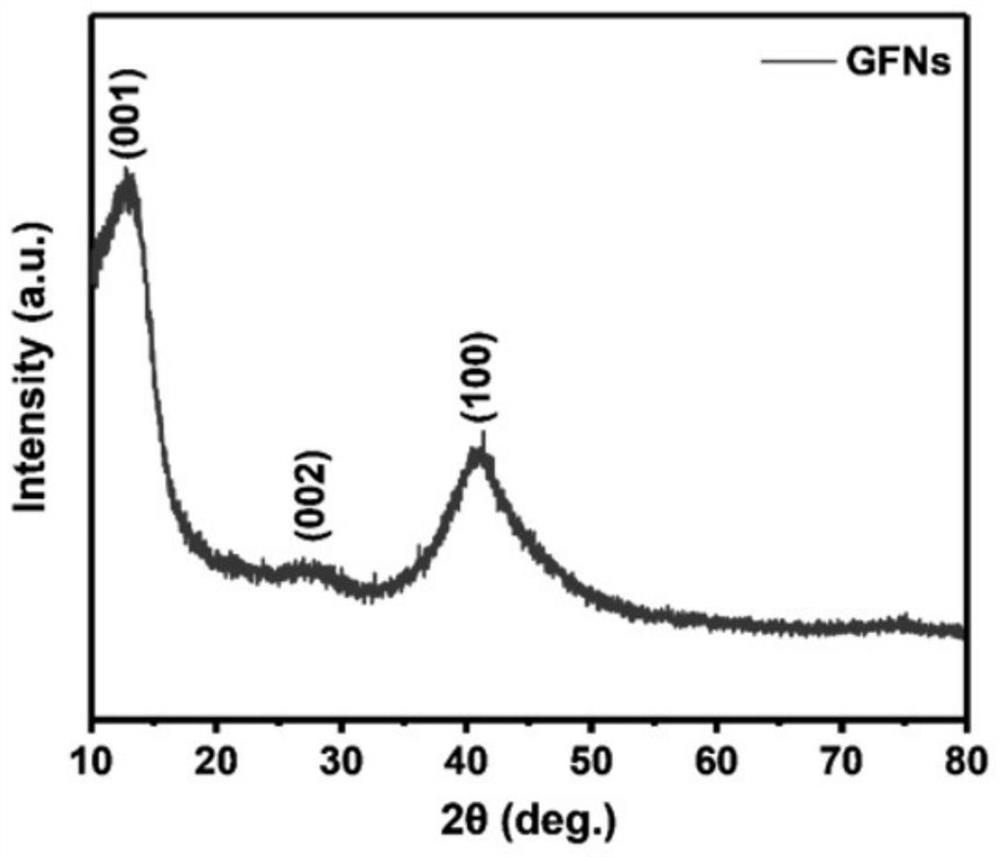

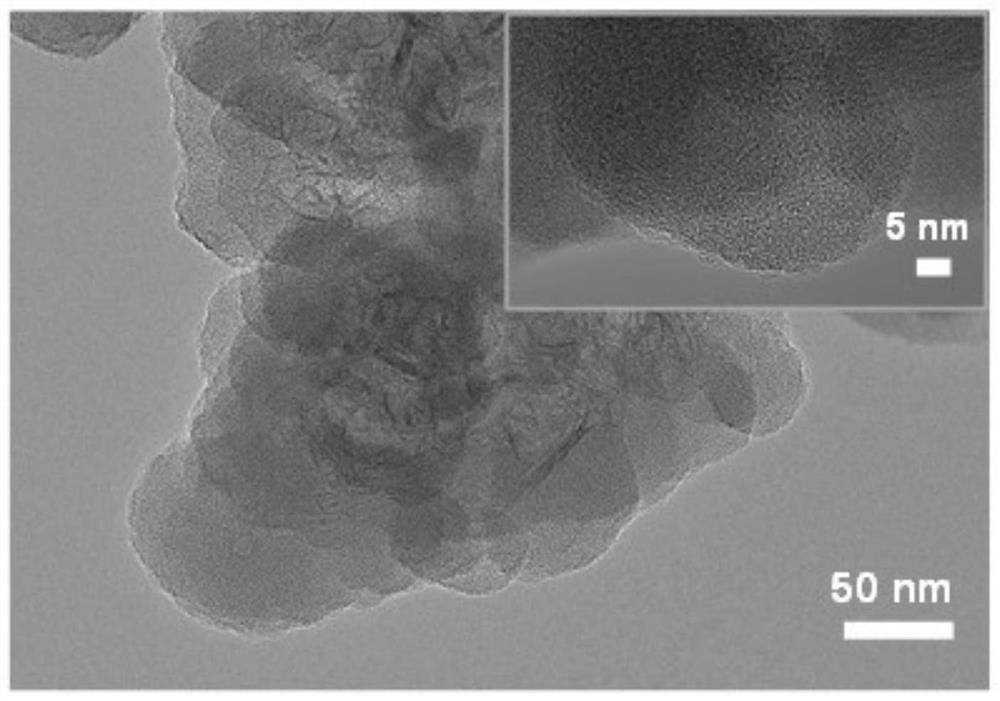

[0046] The embodiment of the present invention provides a dispersion of fluorinated graphite nanosheets, the preparation method of which is as follows:

[0047]Take 1g of fluorinated graphite and add it to 80mL of N-methylpyrrolidone, then raise the temperature to 80°C in a water bath, keep stirring for 3-7h; then, take out the mixed solution and cool it to room temperature, and then place the mixed solution in ultrasonic Sonicate in the machine at room temperature for 30 hours to obtain the mother liquor, and then centrifuge the mother liquor in a centrifuge at a speed of 3000 rpm for 30 minutes; finally, place the centrifuged solution in a dark place for 14-18 days, and take the upper layer solution.

Embodiment 2

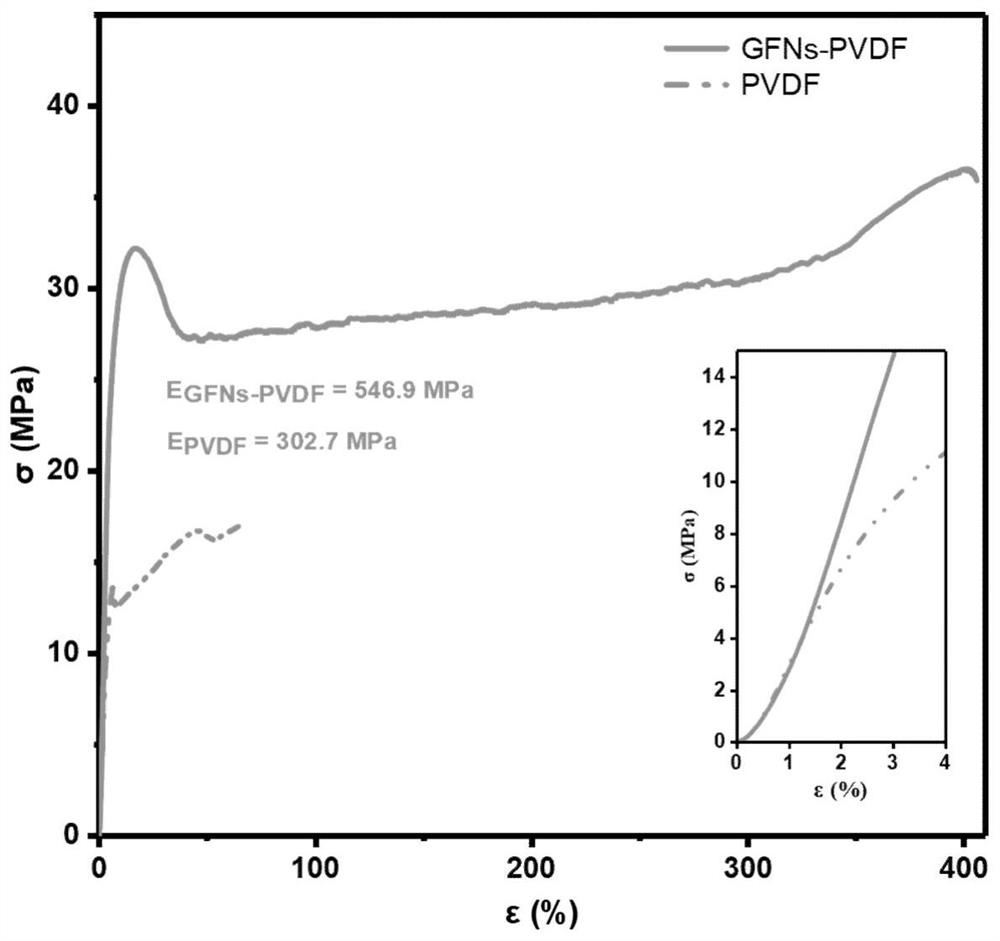

[0049] The embodiment of the present invention provides a fluorinated graphite nanosheet / polyvinylidene fluoride modified diaphragm, the preparation method of which is as follows:

[0050] S1. Preparation of modified slurry for lithium metal battery diaphragm, specifically comprising, weighing 50 mg of polyvinylidene fluoride powder, adding it to 1 mL of the fluorinated graphite nanosheet dispersion prepared in Example 1, and fully stirring until the slurry is transparent Polyvinylidene fluoride powder, you can;

[0051] S2. Apply the lithium metal battery separator modified slurry prepared in step S1 evenly on the surface of the polypropylene separator, then place it in a vacuum drying oven, dry it in vacuum at 60° C. for 12 hours, and take it out after cooling for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com