Positive-negative pressure system, operation method thereof and positive-negative pressure electric appliance using system

An operation method, positive and negative pressure technology, applied in control/regulation systems, instruments, non-electric variable control, etc., can solve problems such as damage to quality and freshness, incompleteness, and unsatisfactory replacement of home appliances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

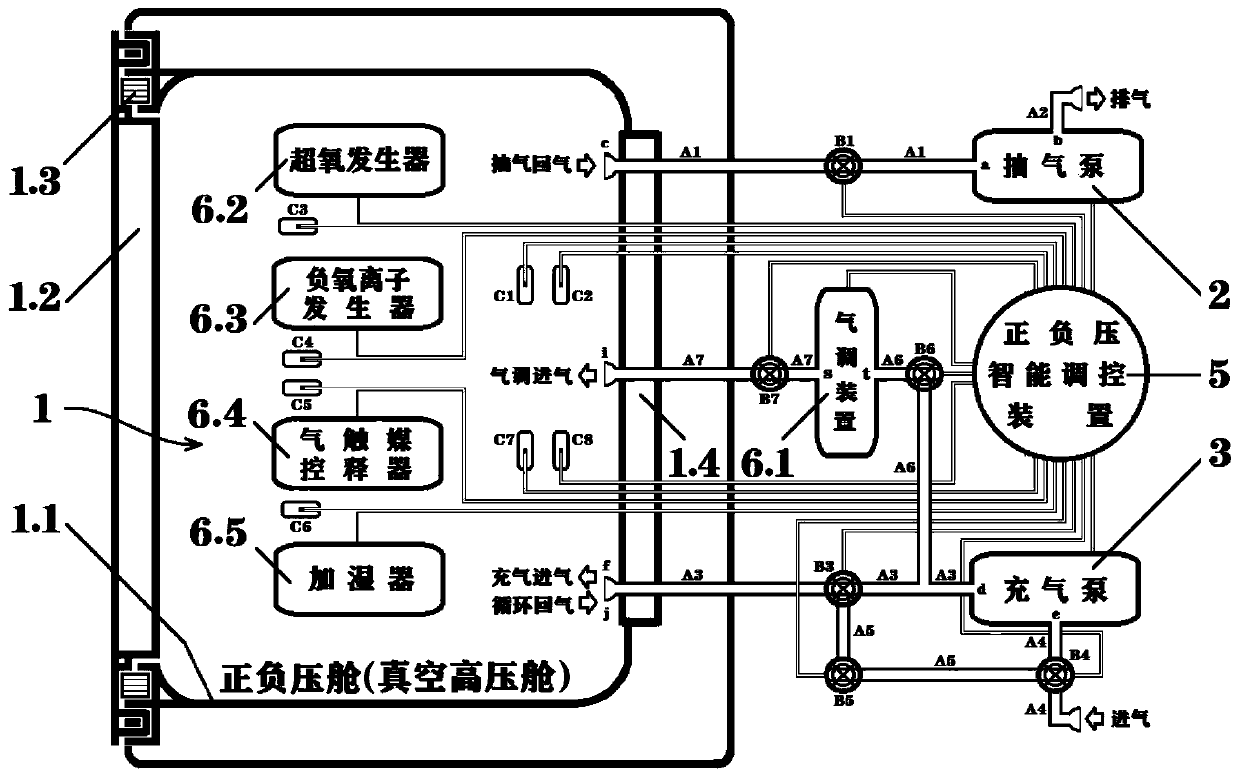

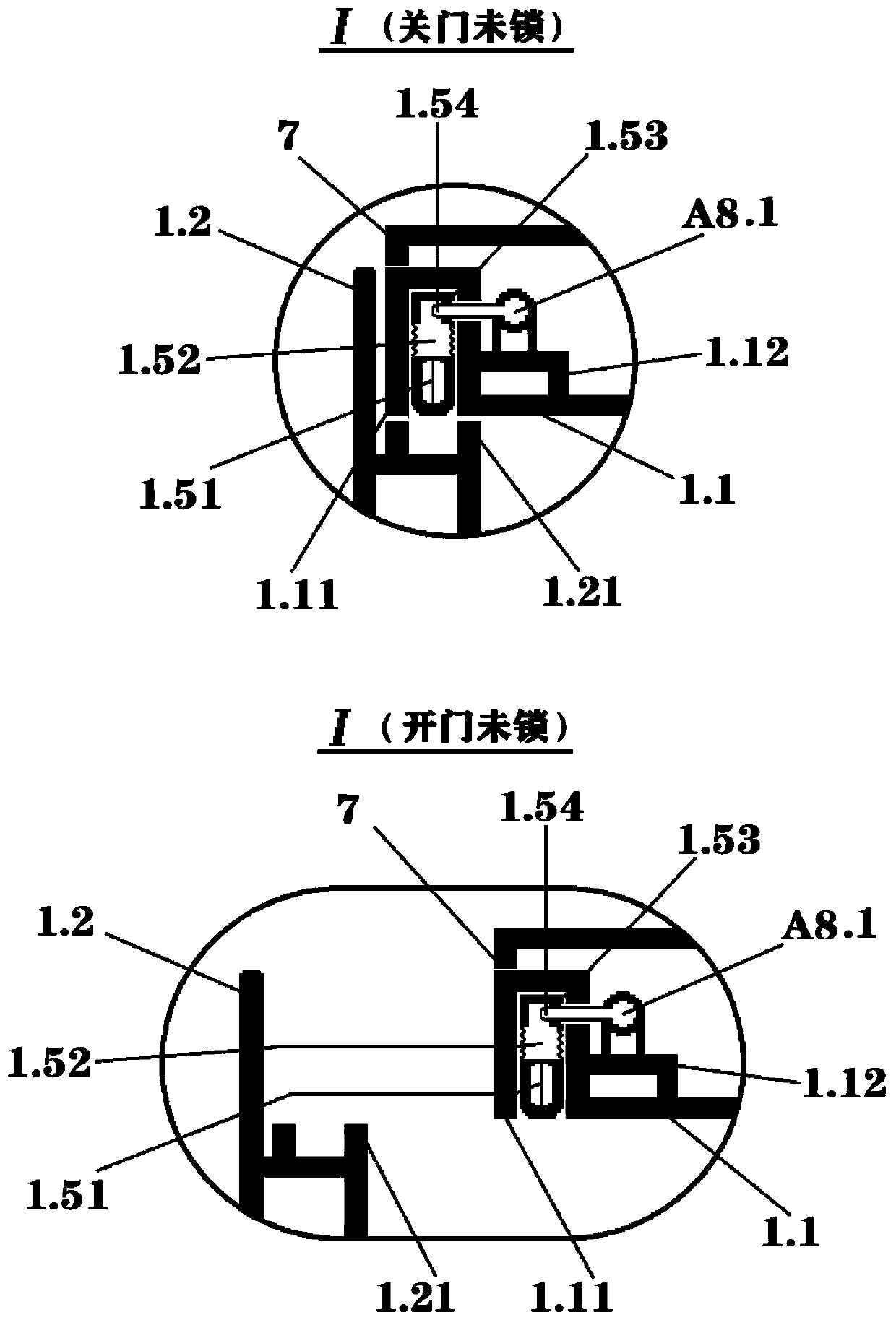

[0046] Specific embodiment one, the intelligent positive and negative pressure system includes: positive and negative pressure cabin 1 (positive and negative pressure cabin also known as: vacuum high pressure cabin), air pump 2, air pump 3, positive and negative pressure intelligent control device 5 and positive and negative pressure chamber The pressurized air flow carrying object generation processor; the positive and negative pressure cabin 1 includes: a cabin body 1.1, a cabin door 1.2, an airtight mechanism 1.3, and a sealer 1.4 for communicating inside and outside the cabin; the cabin body 1.1 and the cabin door 1.2 are arranged An air-tight mechanism 1.3 is installed; the internal and external sealing communicator 1.4 is fixedly arranged at the rear of the positive and negative pressure cabin 1, and all pipelines and circuits entering and leaving the cabin are connected to the internal and external sealing communicator 1.4 and pass through it. In order to maintain the se...

specific Embodiment 2

[0047] Specific embodiment two, the technical principle and basic operation method of the intelligent positive and negative pressure system are: intelligently regulate the air flow with positive and negative pressure, or carry super oxygen, gas catalyst, negative ions, air-modified gas, water and other effective load, orderly enters and exits or resides in a specific space (positive and negative pressure cabin) and exerts the required influence on the items therein; the specific operation method of the intelligent positive and negative pressure system is: the positive and negative pressure intelligent control device 5 according to its built-in program And the pre-stored data and the real-time feedback information of each sensor C1 ~ C8, after calculation and processing, send specific instructions to open or close in real time to the air pump 2, air pump 3, positive and negative pressure air flow carrying object generation processor and solenoid valve, and control Adjust the ope...

specific Embodiment 3

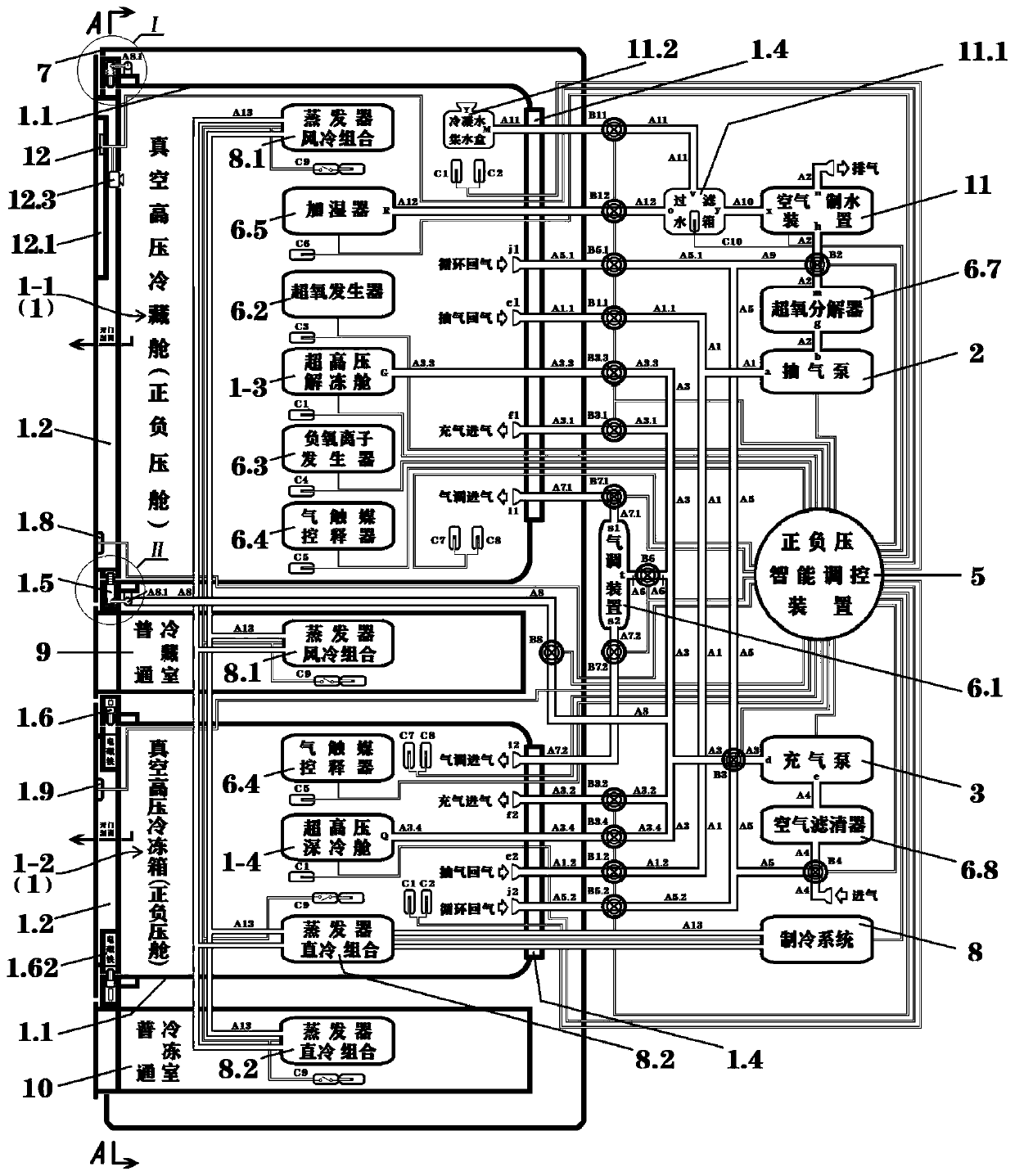

[0048]Specific embodiment three, the intelligent positive and negative pressure refrigerator includes a box body 7; the box body 7 is provided with an intelligent positive and negative pressure system, a refrigeration system 8, a common cold storage room 9, a common freezing room 10, and an air-based water system. Device 11, touch screen and mobile phone monitoring system 12; the intelligent positive and negative pressure system includes a positive and negative pressure cabin 1, an air pump 2, an air pump 3, a positive and negative pressure intelligent control device 5 and a positive and negative pressure air flow carrying object generation processor ; The positive and negative pressure cabin 1 includes: cabin body 1.1, hatch door 1.2, inside and outside the cabin sealing communication device 1.4, pneumatic airtight mechanism 1.5, electric airtight mechanism 1.6, pneumatic hatch switch 1.8, electric hatch switch 1.9; The cabin door 1.2 is the door of the positive and negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com