Method for preparing dfb-ld grating debugging sample by electron beam exposure

A DFB-LD, electron beam exposure technology, applied in the field of microelectronics, can solve the problem of increasing the difficulty of observing the cross section of the electron beam DFB-LD grating, achieve the effect of reasonable exposure time, avoid pattern distortion, and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

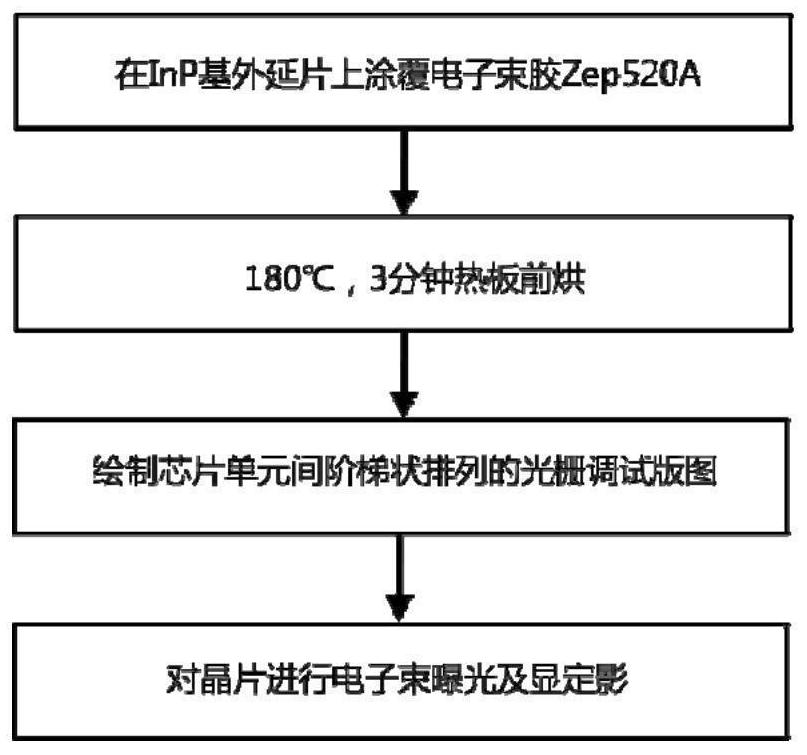

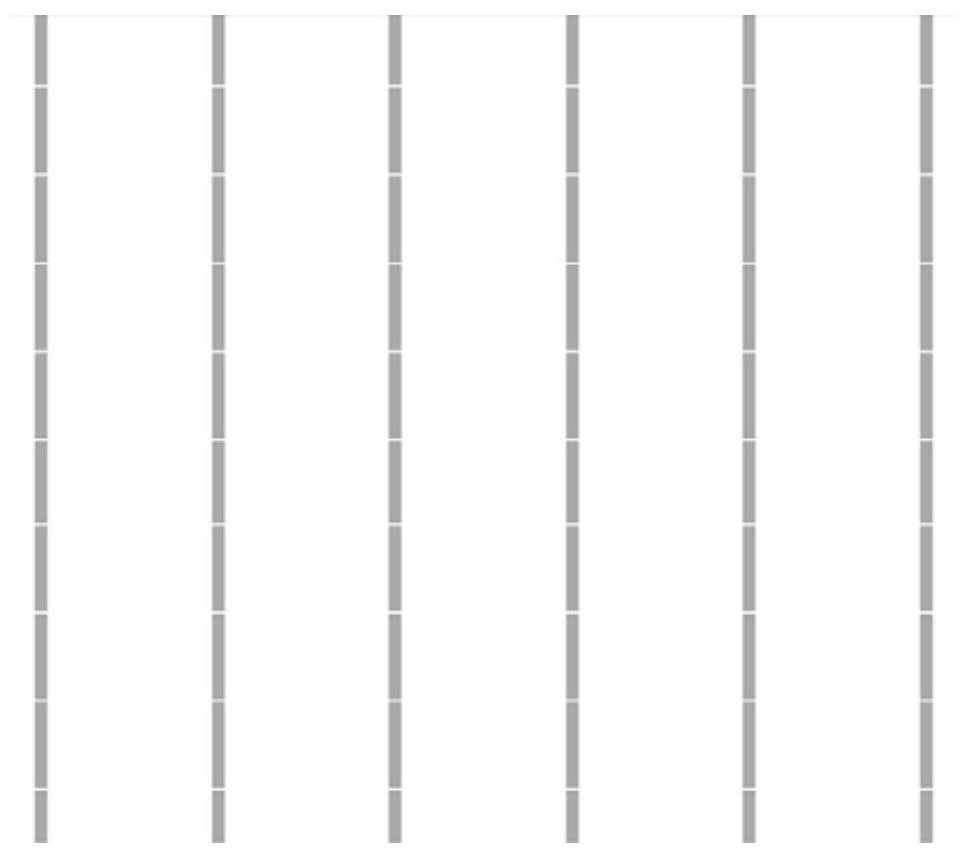

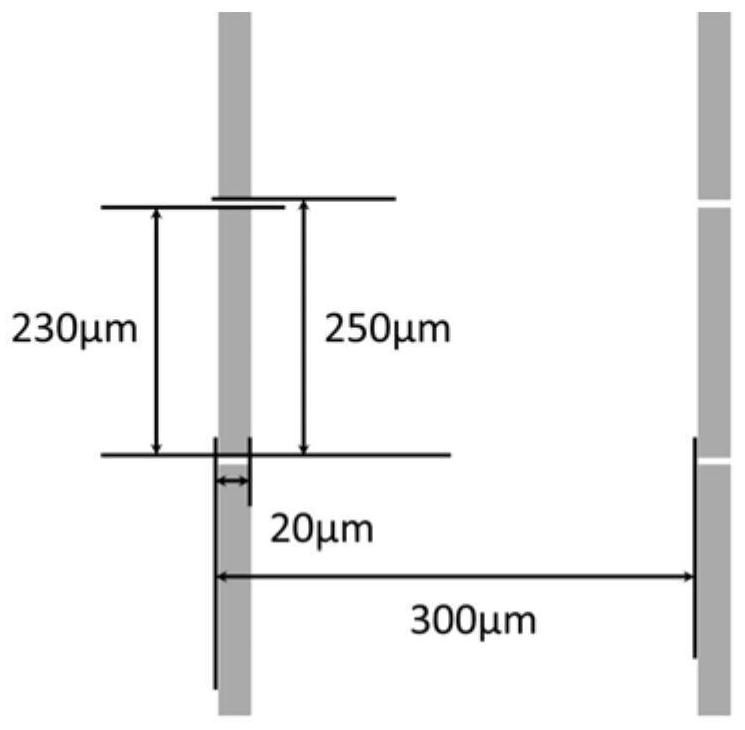

[0032] Such as Figure 1 to Figure 6 Shown, technical scheme of the present invention is:

[0033] A method for preparing DFB-LD grating debugging samples by electron beam exposure, which mainly optimizes the exposure layout according to the requirement of cross-section observation in the grating debugging process, which can greatly improve the efficiency of electron beam preparation of DFB-LD grating cross-section samples. Success rate. In this embodiment, an InP-based epitaxial wafer is taken as an example, and the method includes the following steps:

[0034] Step 1: Coat the electron beam gel Zep520A on the InP-based epitaxial wafer, the coating condition is 4000rpm, and the coating time is 40s;

[0035] Step 2: Put the InP-based epita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com