Improved bimetal plate and manufacturing method thereof

A bimetallic plate and metal plate technology, applied in the direction of manufacturing tools, metal layered products, metal processing equipment, etc., can solve the problems of short service life, low temperature resistance, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

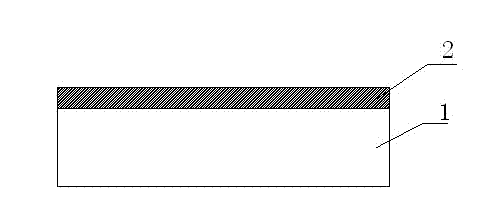

[0012] Such as figure 1 As shown, an improved bimetal plate of the present invention includes a metal plate body 1, and a flux cored layer 2 is provided on the surface of the metal plate body 1. The manufacturing method of the improved bimetallic plate comprises the following steps: taking an ordinary metal plate body 1 of suitable size as a substrate, cleaning and drying the metal plate body 1, and after the metal plate body 1 is fully dried, place the metal plate body 1 A layer of flux-cored welding layer 2 is surfacing by the method of swinging open arc on the surface, and the thickness of the flux-cored welding layer is 5-20mm. An improved bimetallic plate of the present invention, a layer of flux-cored welding layer 2 is surfacing on the surface of the metal plate body 1. Such a structural design can improve the wear resistance and heat preservation performance of the metal plate body 1, making its hardness up to Above HRC60, and the bimetal plate can be cut and assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com