A kind of supported catalyst and its preparation method, the method for catalytic synthesis of n-ethylaniline

A supported catalyst and catalyst technology, applied in the field of catalysis, can solve problems such as low selectivity of N-ethylaniline, and achieve the effects of high selectivity, improved selectivity and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the supported catalyst described in the above technical scheme, comprising the following steps:

[0034] Soluble Cu salt, organic solvent and Al 2 o 3 After mixing, dry to obtain solid product;

[0035] After mixing the solid product, tetraethyl silicate and ethanol, mixing with an alkaline pH regulator, and adjusting the pH value, a catalyst precursor is obtained;

[0036] The catalyst precursor is calcined to obtain the supported catalyst.

[0037] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0038] The present invention combines soluble Cu salt, organic solvent and Al 2 o 3 After mixing, drying afforded a solid product.

[0039] In the present invention, the soluble Cu salt preferably includes one or more of copper nitrate, copper acetate and copper chloride. In the present invention, the organic solvent ...

Embodiment 1

[0059] Take by weighing 241mg copper nitrate trihydrate (1mmol), join in 128g acetone, after stirring and dissolving in the round bottom flask, weigh 128gAl 2 o 3 Add it into a round bottom flask, stir at 35°C for 12h until the acetone evaporates, then dry at 120°C for 3h to obtain a solid product;

[0060] Mix 1.6g tetraethyl silicate and 198mL ethanol to obtain a tetraethyl silicate ethanol solution with a mass concentration of 1.0wt%, add the obtained solid product to the tetraethyl silicate ethanol solution, and stir thoroughly Finally, add ammonia water dropwise, adjust to pH=7.5, make tetraethyl silicate hydrolyze completely, the drip rate of ammonia water is 1mL / min, in Cu(OH) 2 / Al 2 o 3 Surface precipitation forms SiO 2 Thin film, obtain catalyst precursor;

[0061] The obtained catalyst precursors were washed with water in turn until neutral, filtered, and the filter residue was dried at 120°C for 3 hours, then placed in a muffle furnace, heated from room temper...

Embodiment 2

[0065] Take by weighing 400mg copper acetate (2mmol), join in 128g acetone, after stirring and dissolving in the round bottom flask, weigh 128gAl 2 o 3 Add it into a round bottom flask, stir at 35°C for 8h until the acetone volatilizes, then dry at 120°C for 3h to obtain a solid product;

[0066] Mix 3.2g tetraethyl silicate and 196mL ethanol to obtain a tetraethyl silicate ethanol solution with a mass concentration of 2.0wt%, add the obtained solid product to the tetraethyl silicate ethanol solution, and stir thoroughly Finally, add ammonia water dropwise, adjust to pH=7.5, make tetraethyl silicate hydrolyze completely, the drip rate of ammonia water is 1mL / min, in Cu(OH) 2 / Al 2 o 3 Surface precipitation forms SiO 2 Thin film, obtain catalyst precursor;

[0067] The obtained catalyst precursors were washed with water in sequence to neutrality, filtered, and the filter residue was dried at 120°C for 3 hours, then placed in a muffle furnace, heated from room temperature t...

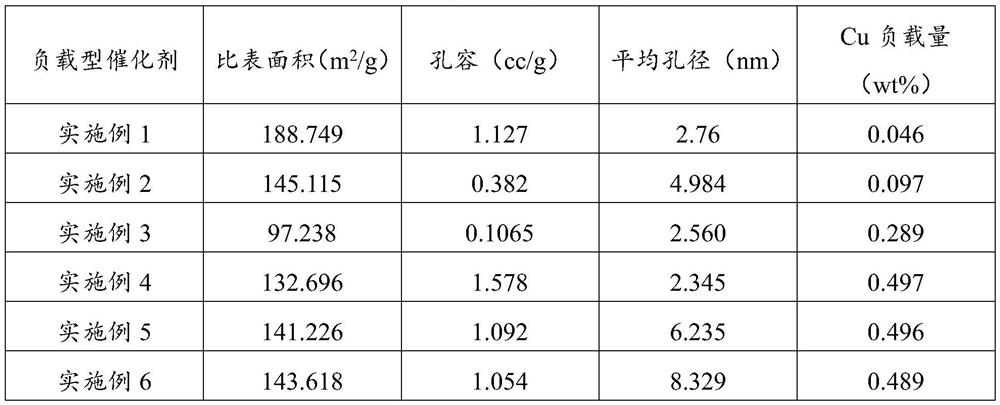

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com