Bipolar plate, fuel cell unit, fuel cell and manufacturing method thereof

A fuel cell unit and bipolar plate technology, which is applied to fuel cells, fuel cell parts, electrical components, etc., can solve the problems of single design, discontinuity, and low fuel concentration of interdigitated bipolar plates, and achieve enhanced The effect of fuel diffusion capacity, improved power generation performance, and uniform distribution of intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a bipolar plate for use in a fuel cell, such as Figure 1 to Figure 7 As shown, the bipolar plate in this embodiment includes an anode plate and a cathode plate. Wherein, in this embodiment, the flow channels at the power generation area of the anode plate are set as interdigitated flow channels 11 , and the flow channels at the power generation area of the cathode plate are set as parallel flow channels 21 .

[0061] The bipolar plate provided in this embodiment can strengthen the fuel diffusion capacity of the anode gas side of the fuel cell and increase the fuel concentration in the catalytic layer in the membrane electrode by setting the flow channel at the power generation area of the anode plate as an interdigitated flow channel 11 . , thereby improving the power generation performance of the fuel cell; at the same time, the flow channel at the power generation area of the cathode plate is set as a parallel flow channel 21, so that...

Embodiment 2

[0064] This embodiment provides a bipolar plate, compared with the previous embodiment, such as Figure 1 to Figure 7 As shown, this embodiment is further designed as follows:

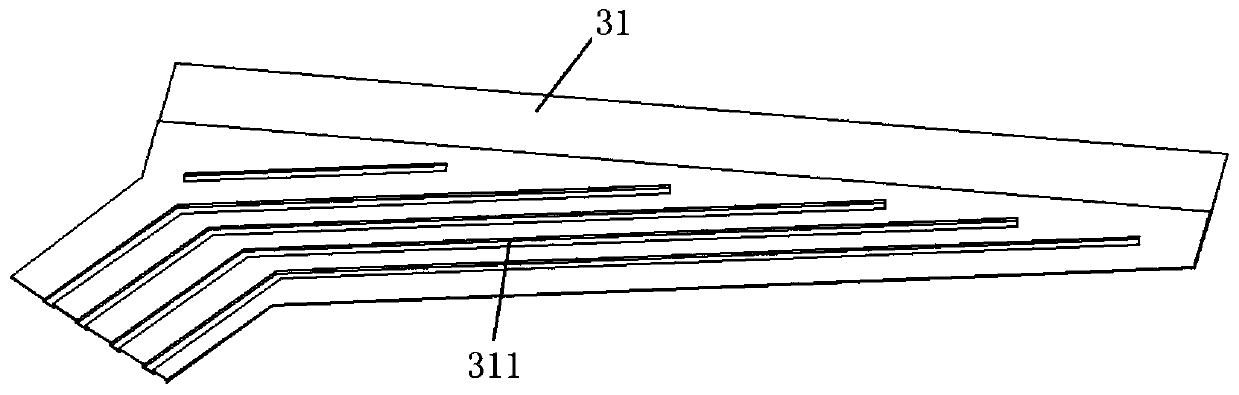

[0065] On the one hand, the anode plate in this embodiment is designed as follows: the anode plate includes an anode plate body 1 and a fuel distribution cover plate. The interdigitated flow channel 11 is located on the anode plate body 1 , and the anode plate body 1 is provided with a fuel inlet 101 , a fuel outlet 106 , an oxidant inlet 103 , and an oxidant outlet 104 . The fuel inlet 101 and the oxidant inlet 103 on the anode plate body 1 are located at one end of the anode plate body 1 , and the fuel outlet 106 and the oxidant outlet 104 are located at the other end of the anode plate body 1 . The interdigitated flow channel 11 is located at the middle position of the anode plate body 1 . Here, the fuel distribution cover plate includes a first fuel distribution cover plate 31 and a second fuel d...

Embodiment 3

[0078] This embodiment provides a bipolar plate, compared with the above-mentioned embodiments, such as Figure 1 to Figure 7 As shown, this embodiment is further designed as follows:

[0079] On the one hand, the anode plate is provided with a cooling liquid inlet 102 and a first cooling liquid distribution area 13; wherein, the first cooling liquid distribution area 13 is located between the cooling liquid inlet 102 and the interdigitated flow channel 11, for The cooling liquid flowing in from the cooling liquid inlet 102 is distributed into the cooling liquid flow field. (like Figure 7 shown in the coolant flow field 73 formed between the anode and cathode plates). Preferably, when the anode plate includes the anode plate body 1 and the fuel distribution cover plate, the cooling liquid inlet 102 and the first cooling liquid distribution area 13 are both arranged on the anode plate body 1 . Here, the cooling liquid inlet 102 is located on the end of the anode plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com