MEMS vibratory gyroscope structure and manufacturing method thereof

A gyroscope, vibrating technology, applied in the field of MEMS vibrating gyroscope structure and its manufacturing, can solve the problems affecting the geometric shape and material properties of the MEMS gyroscope, the accuracy and stability of the MEMS gyroscope, and the imbalance of the gyroscope microstructure. and other problems, to achieve the effect of improving the yield of the device, the method is simple and efficient, and the accuracy and performance are improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

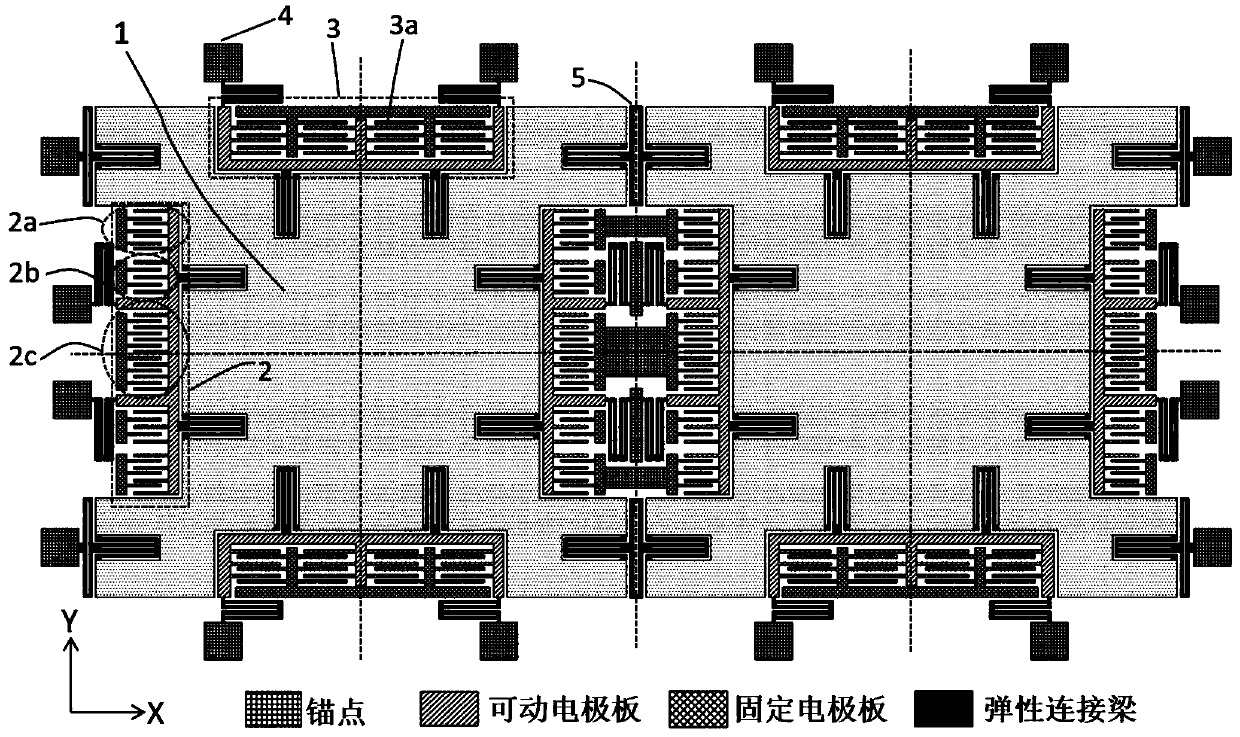

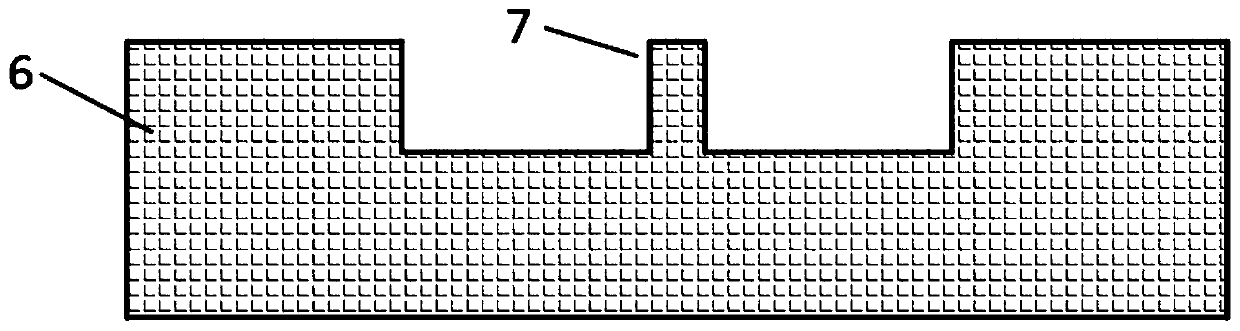

[0042] Embodiment 1: a kind of MEMS vibration type gyroscope, as figure 1 As shown, it includes a cover silicon wafer 10, a structural silicon wafer 9 and a substrate silicon wafer 6. The cover silicon wafer 10, the structural silicon wafer 9 and the substrate silicon wafer 6 are arranged layer by layer from top to bottom to form a vacuum chamber The "sandwich" structure of the MEMS vibrating gyroscope is installed on the structural silicon wafer 9 .

[0043] A cavity structure with support pillars 7 is provided on the substrate silicon wafer 6 , and a layer of silicon oxide layer 8 is deposited on both the front and back sides of the substrate silicon wafer 6 .

[0044] Such as figure 1 As shown, the devices installed on the structural silicon wafer 9 include two mass blocks 1 , four driving frames 2 , four detection frames 3 , several elastic connecting beams 5 and anchor points 4 . The two mass blocks 1 are arranged symmetrically at the left and right centers of the structu...

Embodiment 2

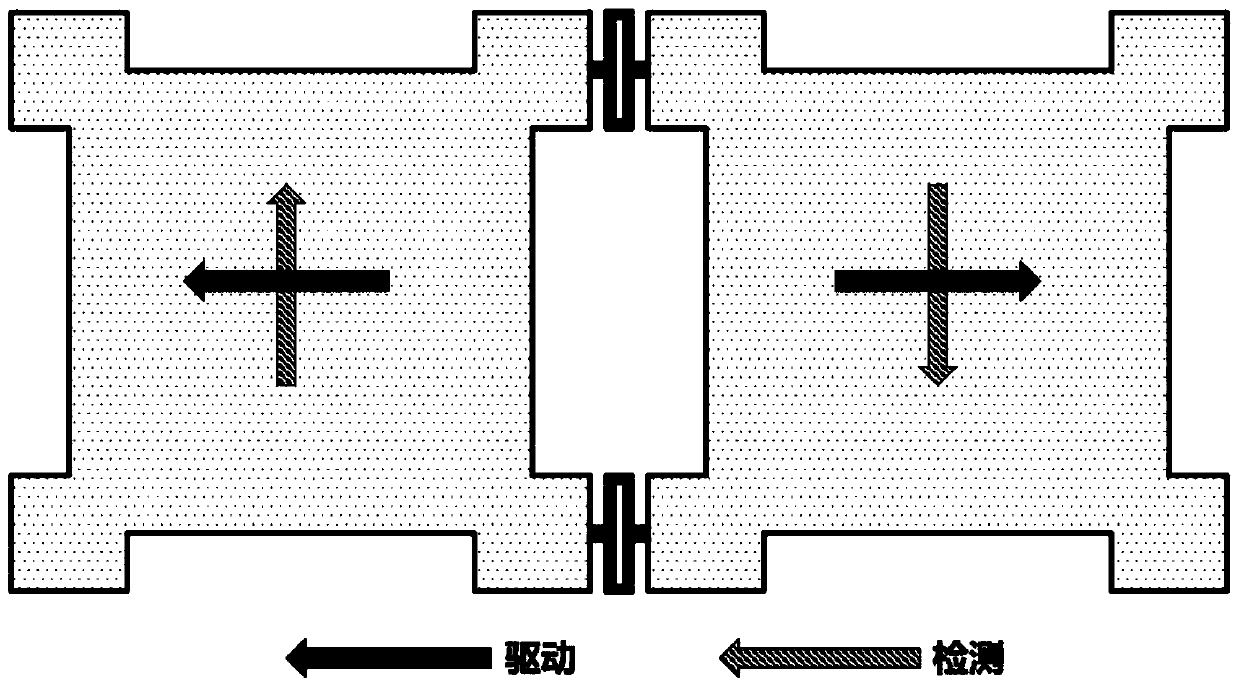

[0059] Embodiment 2: a kind of MEMS vibration type gyroscope, as Figure 4 As shown, the position of the quadrature compensation electrode 2a can be changed, and the quadrature compensation electrode 2a distributed at both ends of the driving frame 2 can be moved to the center position of the left and right masses 1, which can also realize the function of suppressing the quadrature coupling error. The scheme optimizes the electrode arrangement space and arrangement method, wherein various functional electrodes 21 can be flexibly arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com