Preparation method of negative ion formaldehyde-removing water-based paint

A negative ion, aldehyde water-based technology, applied in the field of preparation of negative ion aldehyde-removing water-based paint, can solve the problems of limited application scope, no longer obvious effect, limited amount of adsorbent material added, etc., and achieve the effect of safe air atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

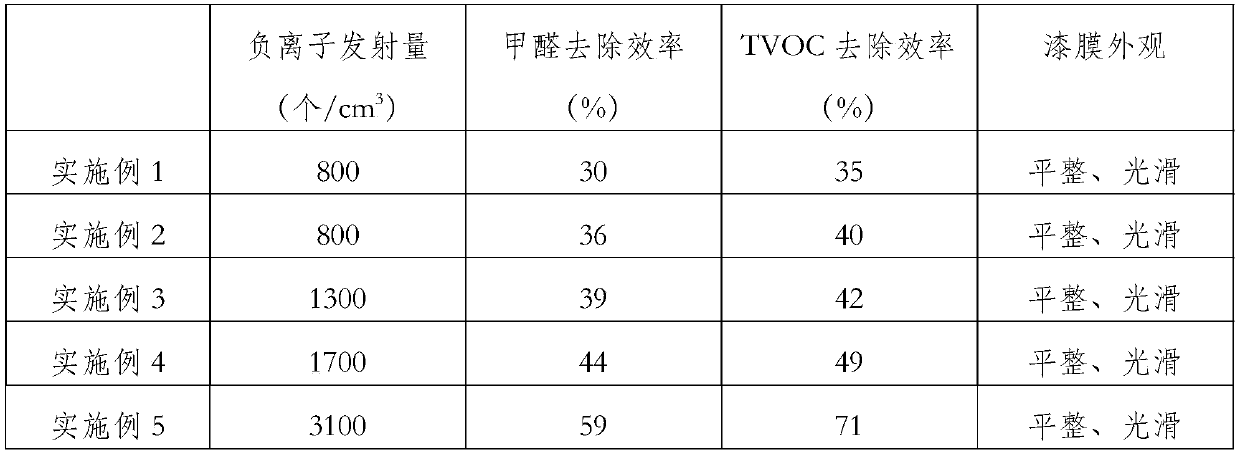

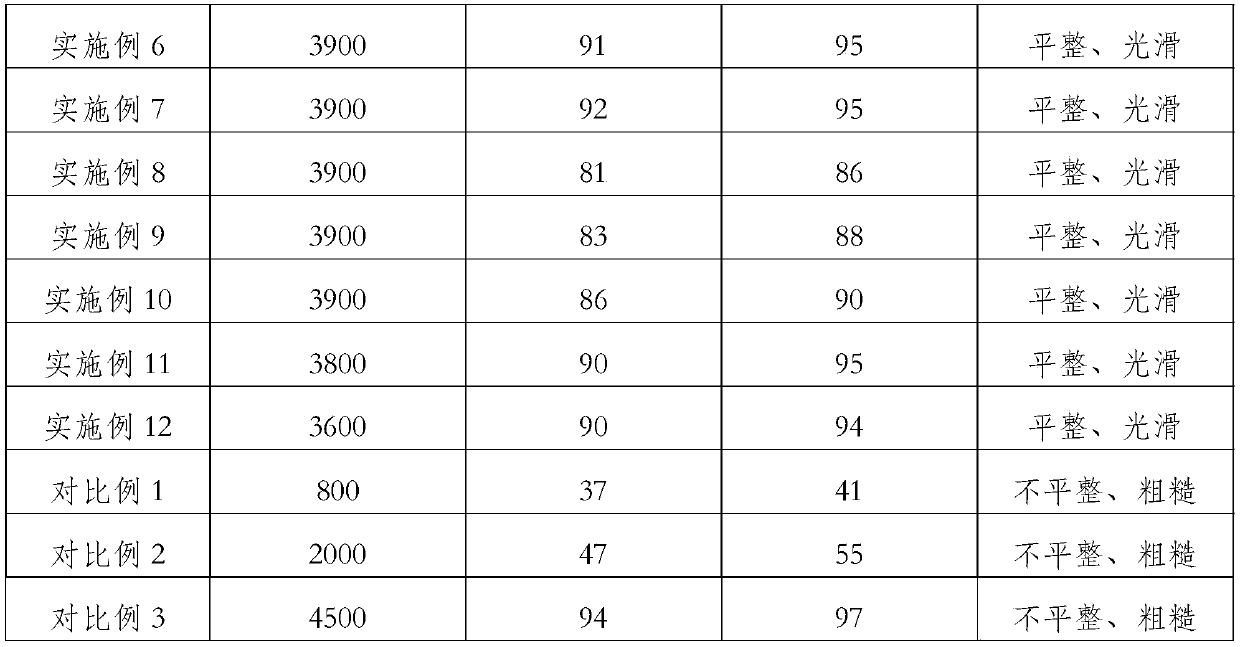

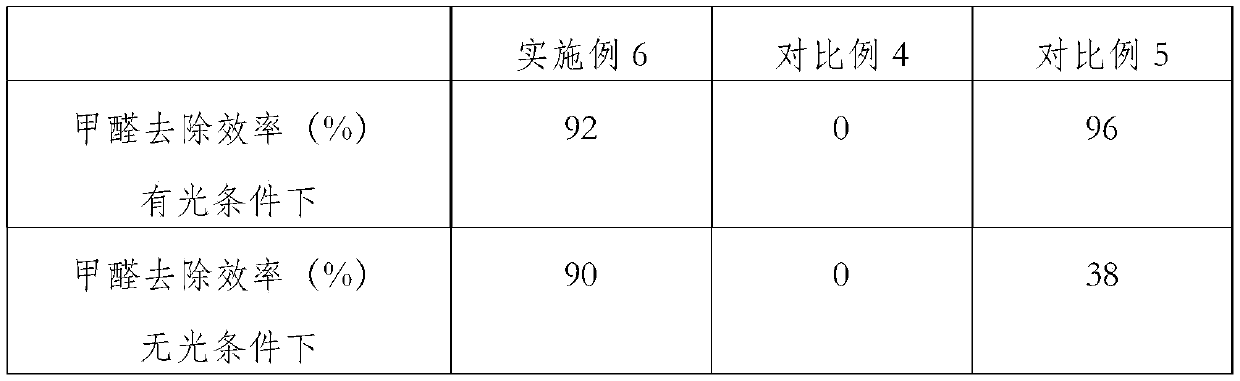

Examples

Embodiment 1

[0029] (1) Negative ion powder is mixed with monazite and tourmaline according to the ratio of 1:1, and is ground into negative ion powder slurry by ball mill. The grinding medium is pure water, the concentration of negative ion powder is 5%, and the particle size of negative ion powder is 80nm. ;

[0030] (2) Mix the potassium tungstate powder and the negative ion powder slurry according to the ratio of 1:1, and mix at a high speed of 1000r / min to obtain a uniform solution to form a negative ion stock solution;

[0031] (3) Add imidazolidinone into water, stir and dissolve at 35°C until uniform, and the concentration of imidazolidinone is 1%, forming an amino-rich aldehyde-removing stock solution;

[0032] (4) adding the negative ion stoste and the amino-rich aldehyde-removing stoste respectively into water and mixing, the mass ratio of the anion-rich stoste is 5%, and the mass ratio of the amino-rich aldehyde-removing stoste is 10%, forming an anion aldehyde-removing liquid;...

Embodiment 2

[0035] (1) Negative ion powder is mixed with monazite and tourmaline according to the ratio of 1:1, and is ground into negative ion powder slurry by ball mill. The grinding medium is pure water, the concentration of negative ion powder is 5%, and the particle size of negative ion powder is 70nm. ;

[0036] (2) Mix the potassium tungstate powder and the negative ion powder slurry according to the ratio of 1:1, and mix at a high speed of 1000r / min to obtain a uniform solution to form a negative ion stock solution;

[0037] (3) Add imidazolidinone into water, stir and dissolve at 35°C until uniform, and the concentration of imidazolidinone is 10%, forming an amino-rich aldehyde-removing stock solution;

[0038] (4) adding the negative ion stoste and the amino-rich aldehyde-removing stoste respectively into water and mixing, the mass ratio of the anion-rich stoste is 5%, and the mass ratio of the amino-rich aldehyde-removing stoste is 10%, forming an anion aldehyde-removing liquid...

Embodiment 3

[0041] (1) Negative ion powder is mixed with monazite and tourmaline according to the ratio of 1:1, and is ground into negative ion powder slurry by ball mill. The grinding medium is pure water, the concentration of negative ion powder is 10%, and the particle size of negative ion powder is 70nm. ;

[0042] (2) Mix the potassium tungstate powder and the negative ion powder slurry according to the ratio of 1:1, and mix at a high speed of 1000r / min to obtain a uniform solution to form a negative ion stock solution;

[0043] (3) Add imidazolidinone into water, stir and dissolve at 35°C until uniform, and the concentration of imidazolidinone is 10%, forming an amino-rich aldehyde-removing stock solution;

[0044] (4) adding the negative ion stoste and the amino-rich aldehyde-removing stoste respectively into water and mixing, the mass ratio of the anion-rich stoste is 5%, and the mass ratio of the amino-rich aldehyde-removing stoste is 10%, forming an anion aldehyde-removing liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com