Integral forming anti-oxidation long-life iron shell tundish water port

An integral forming and anti-oxidation technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of poor resistance to molten steel erosion and slag erosion, weak bonding of the tundish nozzle, and oxidation. Inclusion of impurities and impurities, etc., to achieve enhanced resistance to molten steel erosion and slag erosion, high efficiency and safety, and the effect of reducing air ingress and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In view of the deficiencies in the prior art, the case has been studied for a long time and a large amount of practice, and the technical scheme of the present invention can be proposed. The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

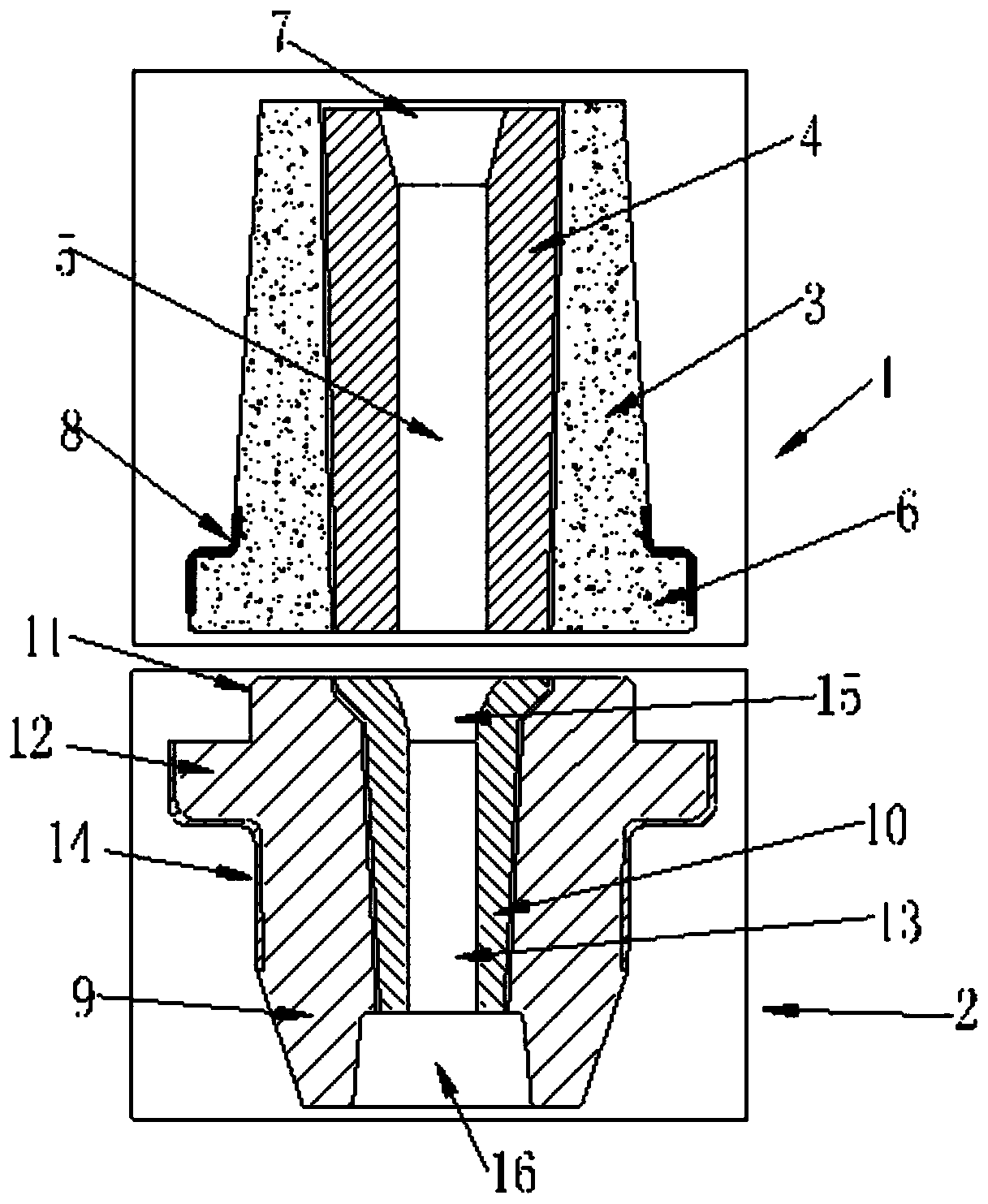

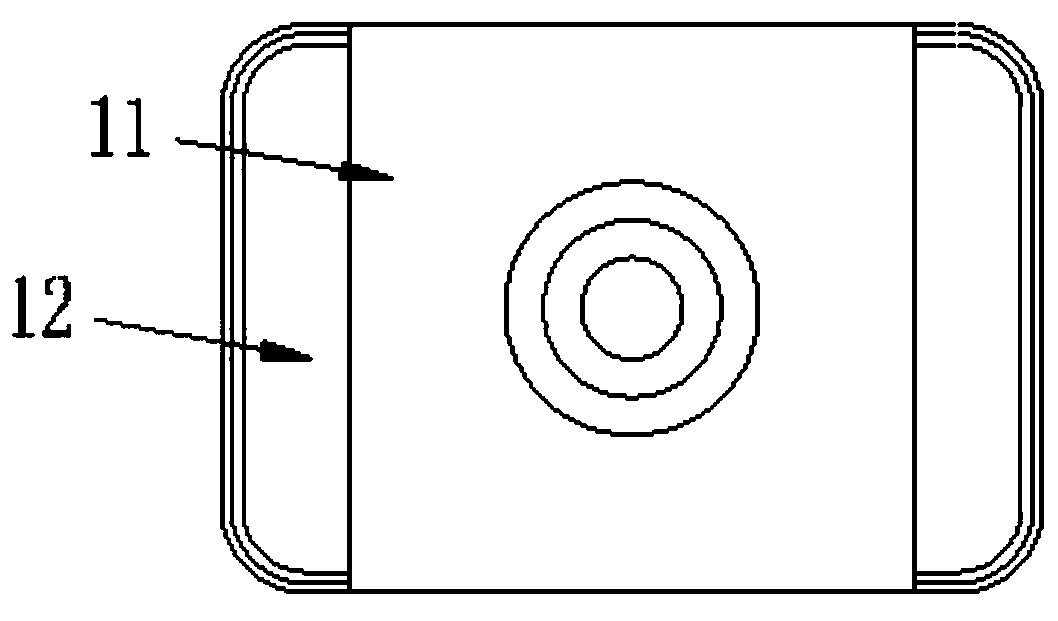

[0019] figure 1 It is a schematic diagram of the nozzle structure of an integrally formed anti-oxidation long-life iron shell tundish provided in the embodiment of the present invention, figure 2 It is a top view of the outlet nozzle of the tundish nozzle of an integrally formed anti-oxidation long-life iron shell of the present invention. Such as figure 1 and figure 2 As shown, an integrally formed anti-oxidation long-life iron shell tundish nozzle provided in the embodiment of the present invention includes an upper nozzle 1 and a lower nozzle 2, and the upper nozzle 1 is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com