Corrosion-resistant and high-temperature-resistant cable

A corrosion-resistant, high-temperature technology, applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of easy corrosion, anti-stripping performance affecting service life, etc., to achieve not easy to break, good anti-stripping performance, high temperature resistance and corrosion resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

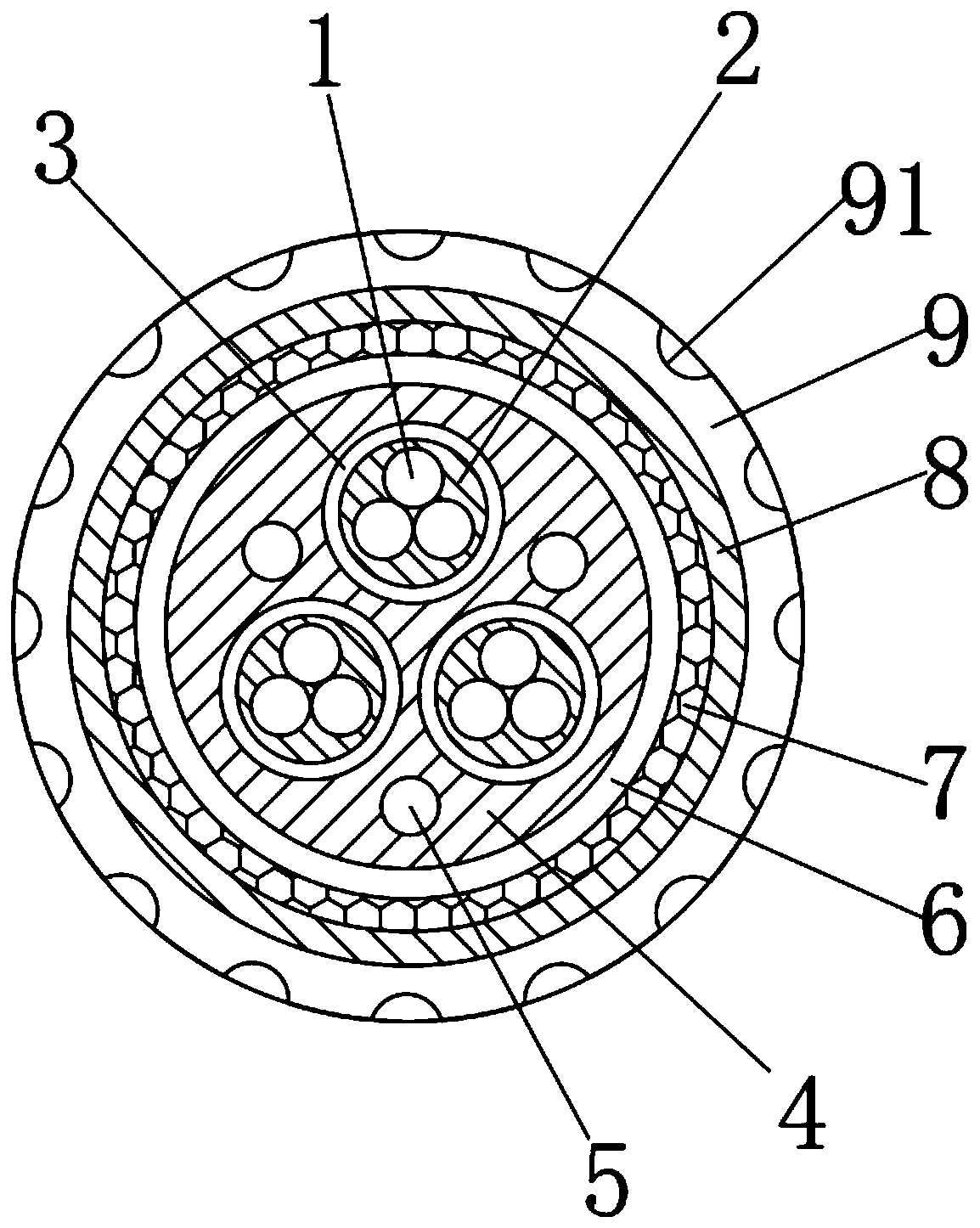

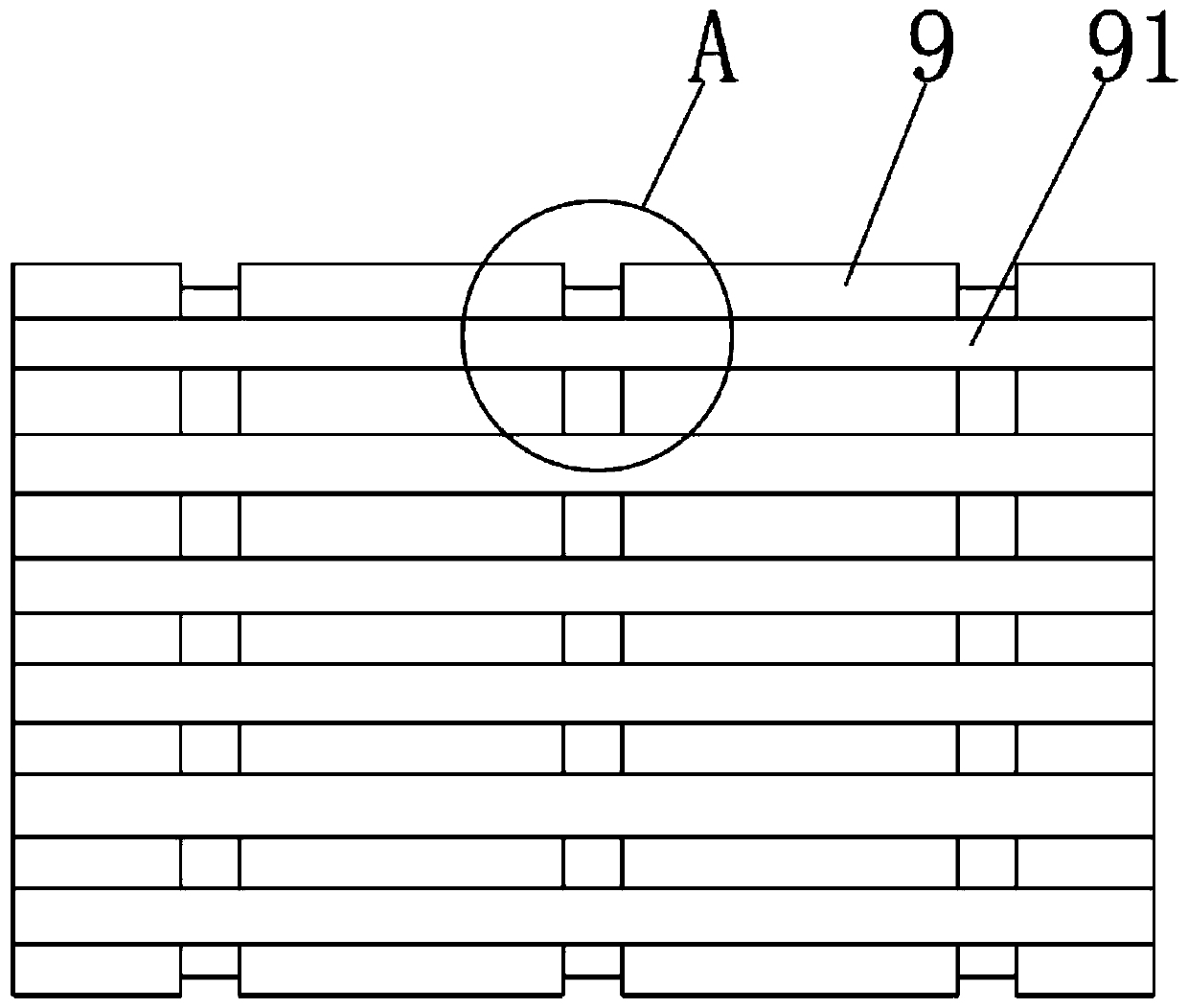

[0020] During specific implementation: if Figure 1 to Figure 3 As shown, a corrosion-resistant high-temperature cable includes a wire core 1, the outside of the wire core 1 is covered with a core layer 2, and the outside of the core layer 2 is covered with a rubber inner layer 3, and the rubber inner layer The outer side of the layer 3 is covered with a water-blocking layer 4, the interior of the water-blocking layer 4 is interspersed with carbon fiber threads 5, the outer side of the water-blocking layer 4 is covered with a rubber middle layer 6, and the outer side of the rubber middle layer 6 is covered There is a woven mesh layer 7, the outer side of the woven mesh layer 7 is bonded with a tackifying layer 8, the outer side of the tackifying layer 8 is covered with a rubber outer layer 9, and the outer side of the rubber outer layer 9 is provided with a transverse concave Groove 91 and radial groove 92.

[0021] By designing the rubber outer layer 9, the raw materials use...

Embodiment 2

[0034] During specific implementation: if Figure 1 to Figure 3 As shown, a corrosion-resistant high-temperature cable includes a wire core 1, the outside of the wire core 1 is covered with a core layer 2, and the outside of the core layer 2 is covered with a rubber inner layer 3, and the rubber inner layer The outer side of the layer 3 is covered with a water-blocking layer 4, the interior of the water-blocking layer 4 is interspersed with carbon fiber threads 5, the outer side of the water-blocking layer 4 is covered with a rubber middle layer 6, and the outer side of the rubber middle layer 6 is covered There is a woven mesh layer 7, the outer side of the woven mesh layer 7 is bonded with a tackifying layer 8, the outer side of the tackifying layer 8 is covered with a rubber outer layer 9, and the outer side of the rubber outer layer 9 is provided with a transverse concave Groove 91 and radial groove 92.

[0035] By designing the rubber outer layer 9, the raw materials use...

Embodiment 3

[0048] During specific implementation: if Figure 1 to Figure 3 As shown, a corrosion-resistant high-temperature cable includes a wire core 1, the outside of the wire core 1 is covered with a core layer 2, and the outside of the core layer 2 is covered with a rubber inner layer 3, and the rubber inner layer The outer side of the layer 3 is covered with a water-blocking layer 4, the interior of the water-blocking layer 4 is interspersed with carbon fiber threads 5, the outer side of the water-blocking layer 4 is covered with a rubber middle layer 6, and the outer side of the rubber middle layer 6 is covered There is a woven mesh layer 7, the outer side of the woven mesh layer 7 is bonded with a tackifying layer 8, the outer side of the tackifying layer 8 is covered with a rubber outer layer 9, and the outer side of the rubber outer layer 9 is provided with a transverse concave Groove 91 and radial groove 92.

[0049] By designing the rubber outer layer 9, the raw materials use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com