Cantilever beam type MEMS magnetic sensor and preparation method thereof

A cantilever-type, magnetic sensor technology, applied in the field of sensors, can solve the problems of limited acoustic wave disturbance ability, difficulty in increasing disturbance signals, and limited ability to detect weak magnetic fields, etc., and achieves the effect of low cost and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing:

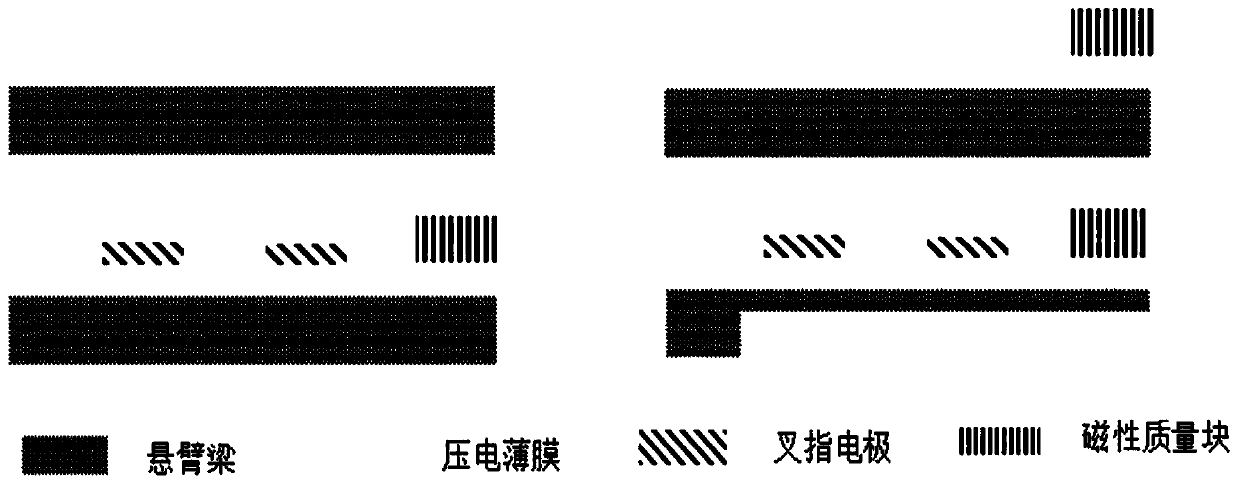

[0027] see Figure 1 to Figure 2 , a cantilever beam type MEMS magnetic sensor, comprising a silicon-based cantilever beam 1 , a surface acoustic wave device 4 , a magnetostrictive film 5 , and a magnetic mass block 6 . The surface acoustic wave device 4 is arranged above the silicon-based cantilever beam 1 ; the surface acoustic wave device 4 is composed of a piezoelectric film 2 and interdigital electrodes 3 ; the magnetic mass 6 is located at the free end of the silicon-based cantilever beam 1 .

[0028] The cantilever consists of a silicon substrate. The silicon substrate conforms to the semiconductor process, has low cost, and is easy to produce in large quantities.

[0029] The surface acoustic wave device is composed of a piezoelectric film and interdigital electrodes.

[0030] The surface acoustic wave device is a single port or delay line structure. In this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com