Square billet center macrosegregation analysis method

A technology of macro segregation and analysis method, which is applied in the field of analysis and evaluation of billet center macro segregation, which can solve problems affecting detection, reliability and guidance of analysis results, and achieve the effect of improving representativeness and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1. Continuous casting slab sampling:

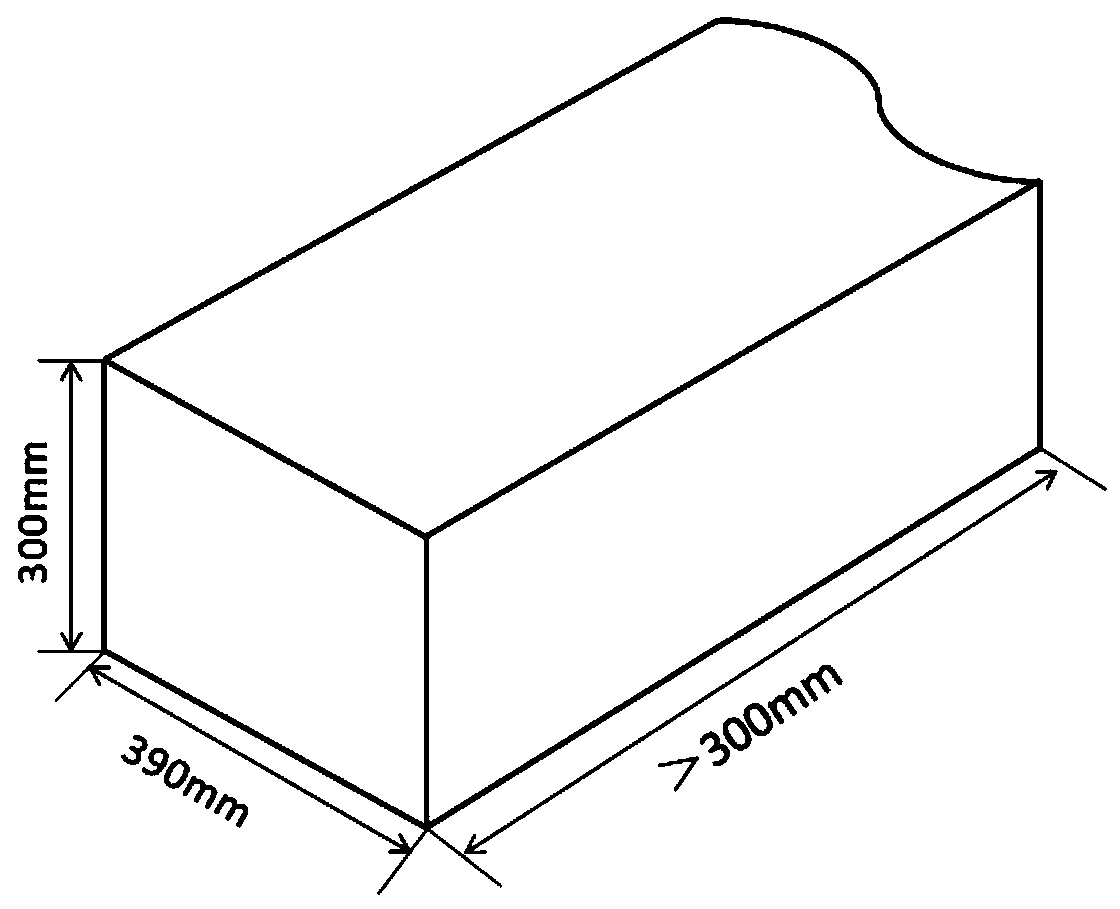

[0031] Cut the continuous casting billet section with a length of 350mm on the billet continuous casting billet to be analyzed (such as figure 1 As shown), cut low-magnification samples on the continuous casting slab section, and keep a distance of 20mm between the sample cutting area and the casting slab cutting area, avoiding the heat-affected zone of flame cutting.

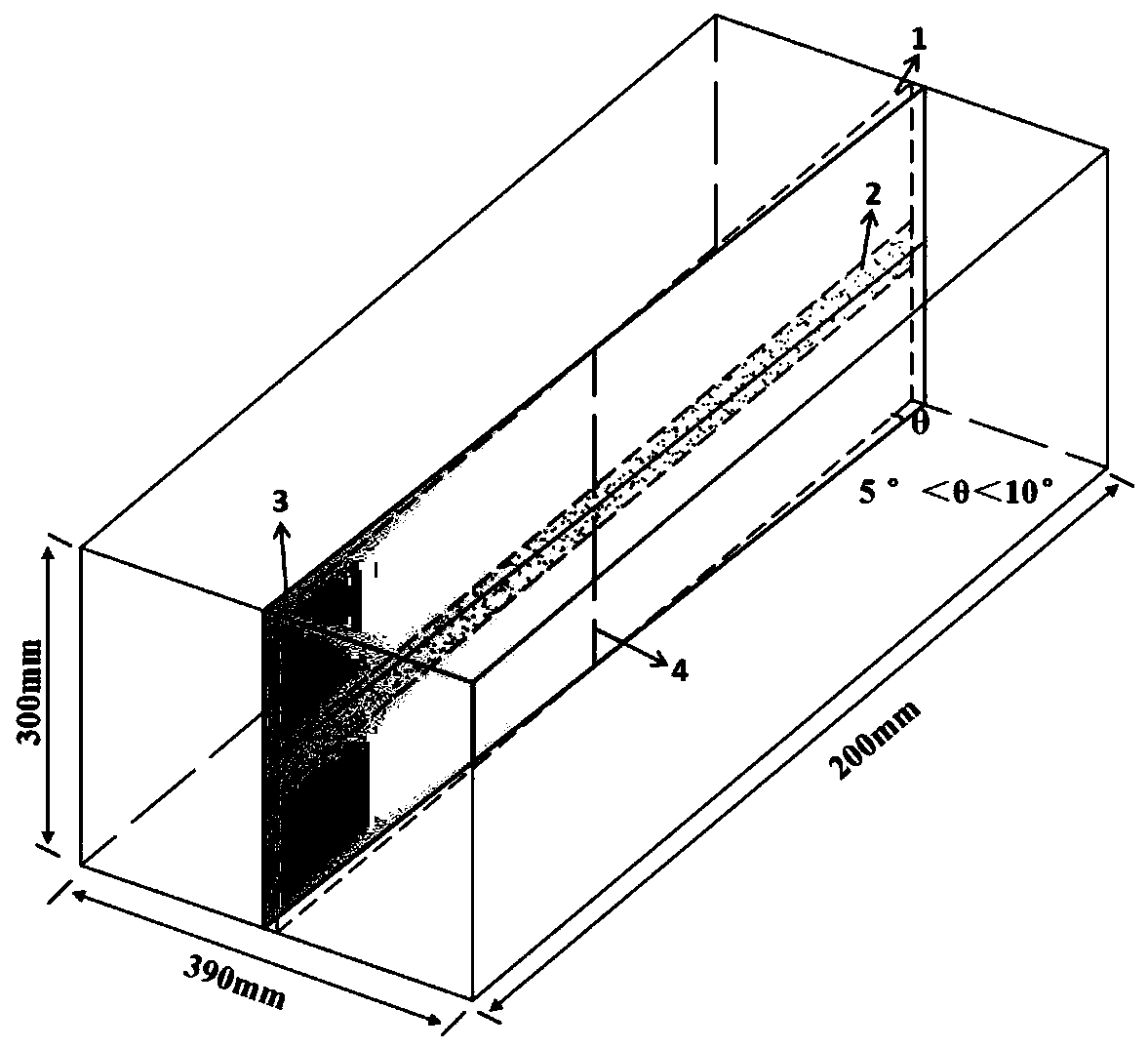

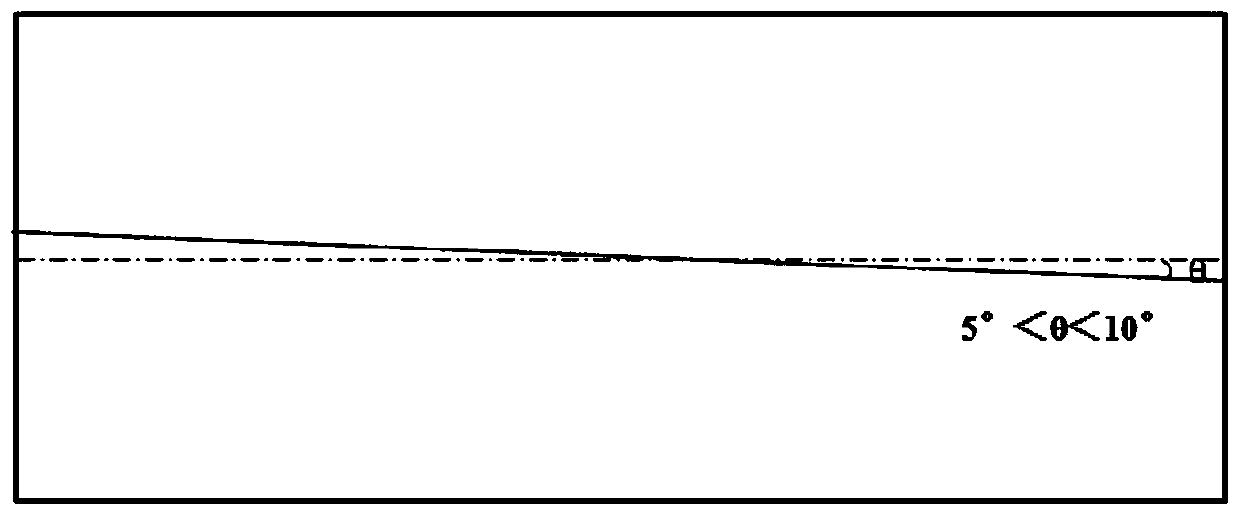

[0032] Sampling Sampling along the drawing direction. For sampling in the drawing direction, the present invention adopts cutting and sampling on a vertical plane with an included angle of 8° with the central longitudinal section of the billet, and the sample length is 200 mm long, such as figure 2 , image 3 , Figure 4 shown.

[0033] 2. Sample processing and storage:

[0034] Before pickling the low-magnification tissue, mill the cut surface (test surface) so that the roughness of the test surface of the sample is Ra≤0.8μm, and there should be no wear marks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com