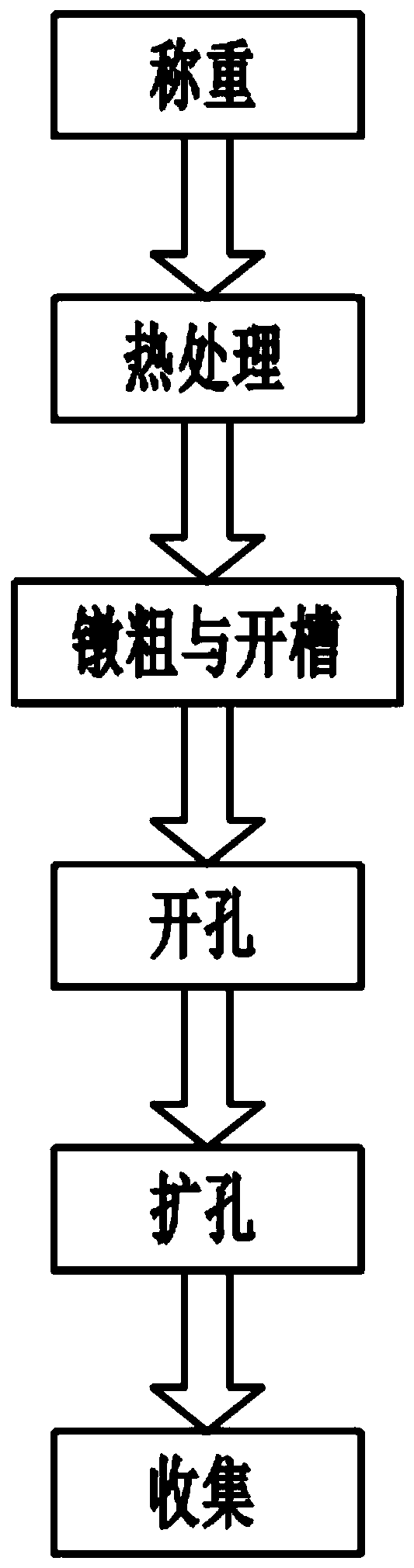

Rolling ring production process

A production process and ring rolling technology, applied in the field of ring rolling production process, can solve problems such as difficulty in opening holes, save manpower and material resources, improve mechanical properties, and improve plastic processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

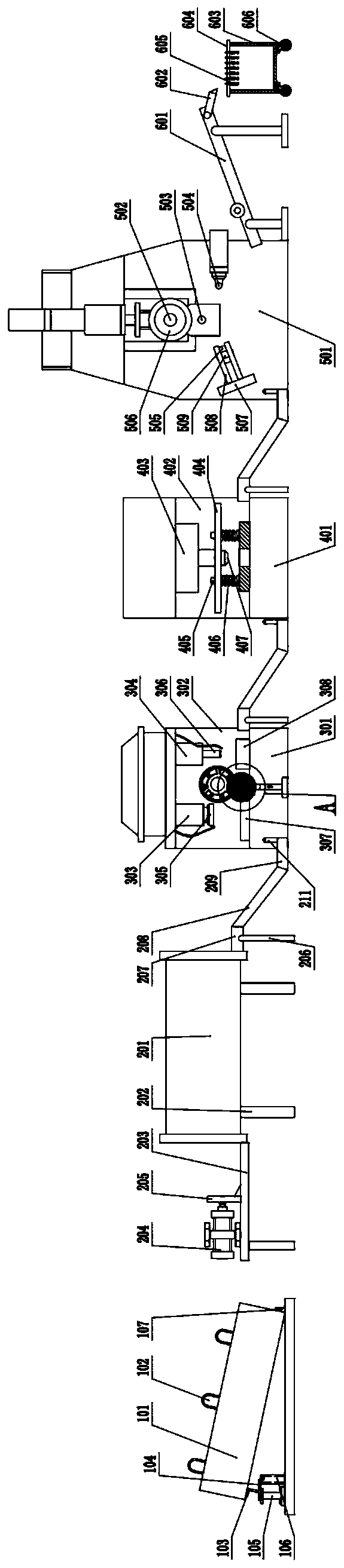

[0037] The following is further described in detail through specific implementation methods:

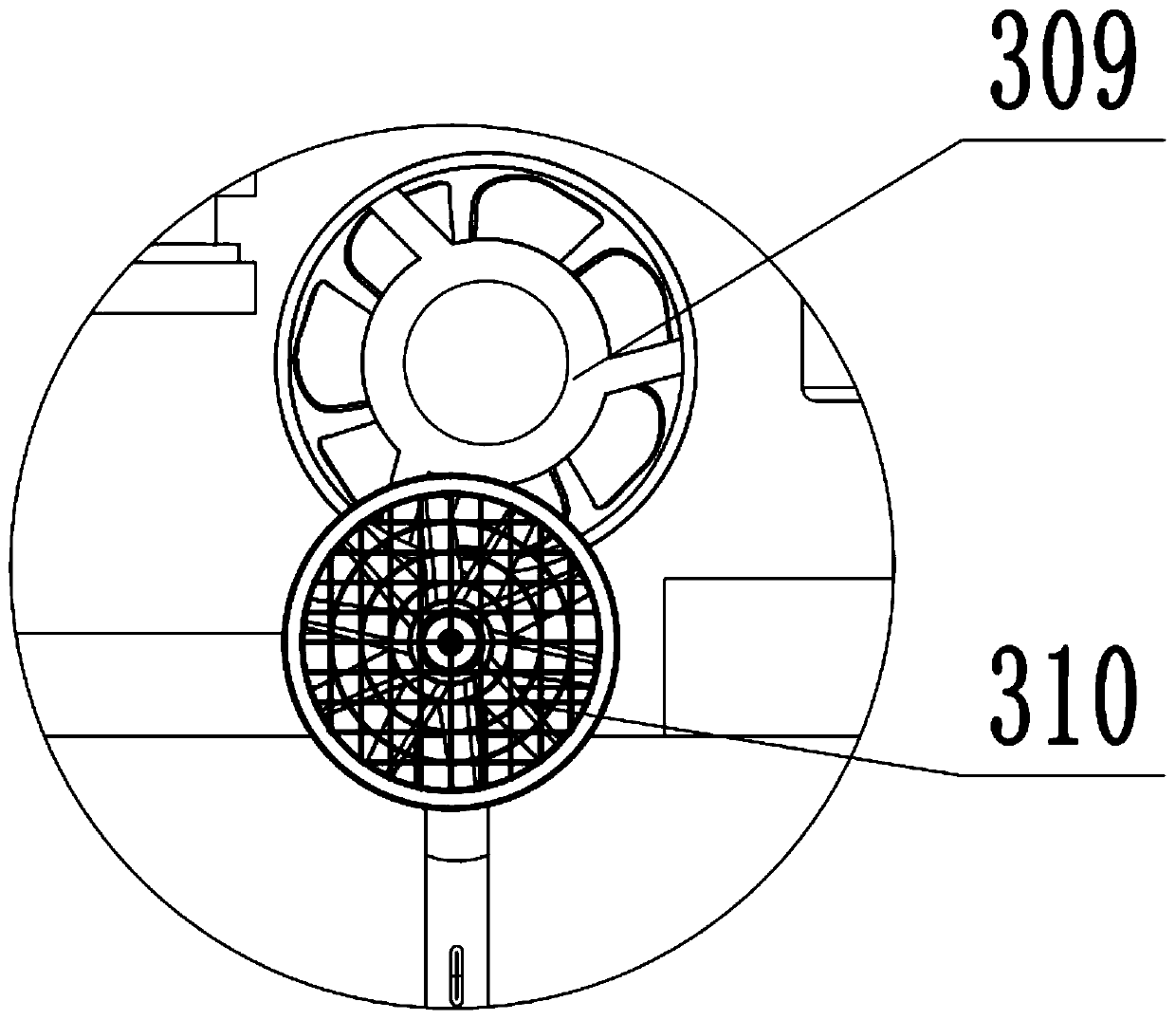

[0038] The reference numerals in the drawings of the description include: charging box 101, hanging lug 102, support member 103, hook 104, support column 105, positioning cylinder 106, stopper 107, continuous heating furnace 201, support frame 202, conveying plate 203, the first telescopic oil cylinder 204, the push plate 205, the legs 206, the first material guide 207, the second material guide 208, the third material guide 209, the baffle plate 211, the first workbench 301, the first support Seat 302, second and fourth telescopic oil cylinders 03, third and fourth telescopic oil cylinders 04, upsetting hammer 305, extrusion rod 306, upsetting table 307, extrusion table 308, negative pressure fan 309, positive pressure fan 310, the first Second workbench 401, second support seat 402, fourth telescopic oil cylinder 403, bearing plate 404, slide rod 405, compression spring 406, hole h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com